Chemical Storage and Segregation - chemical storage

Choose from a variety of wording, materials, and graphics to perfectly match your building’s needs. If you can't find exactly what you're looking for, we're here to help — contact us for custom signage solutions!

For those looking for a deep dive into pre-shift hoist inspections, HMI produced a webinar focused solely on this topic. In addition to hoist inspection publications, HMI offers a variety of other technical resources — including a comprehensive library of product guides; a hoist certification program; OSHA Alliance safety tip sheets, fact sheets and quick cards; multiple technical papers and more — via its website at www.MHI.org/hmi.

“The pre-shift hoist inspection should also include any guidelines or areas for assessment recommended by the hoist’s manufacturer,” Frazier added. “Those are in the equipment owner’s manual.”

“For operations needing more help with establishing a pre-shift hoist inspection process, HMI offers a comprehensive guide. HMI 100.24 Hoist Inspection and Maintenance Manual is a free download,” said Frazier. “The manual also includes helpful checklists that detail these key inspection areas.”

Also, the operator should document the findings of every pre-shift hoist inspection, either on paper or electronically. The facility should retain those records to confirm they are being performed and to identify any areas of concern or patterns of wear.

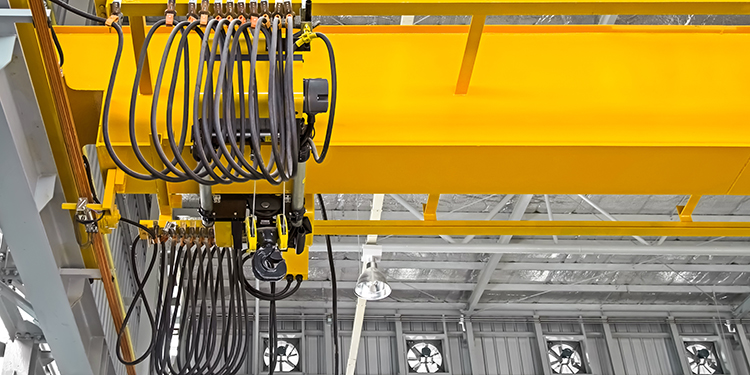

Pre-shift hoist inspections are important because hoists lift and lower heavy loads overhead. A hoist failure could potentially lead to the load falling from its suspended height, endangering the lives of personnel. A drop could also damage the lifted product, surrounding equipment, and facility structures.

Multiple safety regulations and standards call for performing pre-shift hoist inspections. Sources include the Occupational Safety and Health Administration (OSHA), the American Society of Mechanical Engineers (ASME), and HMI. Applicable codes and standards are:

The Overhead Alliance is the marketing arm to the Crane Manufacturers Association of America (CMAA), the Hoist Manufacturers Institute (HMI) and the Monorails Manufacturers Association (MMA) which provides information on the benefits of using overhead lifting technologies and safety.

MHI is the nation’s largest material handling, logistics and supply chain association. MHI offers education, networking and solution sourcing for members, their customers and the industry as a whole through programming and events. Learn more about MHI.

Indicate the location of fire extinguishers and fire hoses within buildings like apartments, condominiums, offices, industrial buildings, warehouses, schools, hospitals and more with Safety Media's highly-visible signage. It's mandatory to have fire extinguisher signage wherever an extinguisher is mounted. For guidance on proper placement, refer to this NFPA guide. Our signage options include:

There are several key areas to assess when performing a pre-shift hoist inspection, noted Matthew Frazier, Senior Manager of Engineering in New Product Development at HMI member Columbus McKinnon. Frazier presented this portion of the webinar.

Before using a wire rope, chain, or lever hoist for the first time during a shift or day, it’s important that the operator perform a pre-shift hoist inspection. These inspections, recommended by the Hoist Manufacturers Institute (HMI), ensure the safety of personnel and the proper functioning of the hoist. The HMI Technical Committee recently presented a webinar, “Dos and Don’ts of Safe Hoist Operation,” highlighting several best practices — including inspections. Ultimately, pre-shift hoist inspections keep an overhead lifting operation safe.

Additionally, routinely verifying that a hoist is in safe, proper operating condition maximizes productivity. This confirmation reduces the risk of unplanned downtime and can extend the service life of the hoist.

Ms.Cici

Ms.Cici

8618319014500

8618319014500