Zinc Selenide Lens, ZnSe Lenses - zinc selenide lens

Now, understand that these results below are subjective; they are my opinion. What one metrologist, scientist, or technician determines as the resolution uncertainty may not agree with another. It is subject to interpretation, capability, and skill. So, be sure to use your best judgment and common sense.

The NHS ester (or succinimidyl ester) is the most popular amine reactive group for labeling with the primary amines (R-NH2) of proteins, amine-modified oligonucleotides, and other amine-containing molecules. The resulting CyDye conjugate will exhibit brighter fluorescence and greater photostability than the conjugates of other spectrally similar fluorophores.

Food service hot and cold temperature log sheets are tedious yet essential in rounding out your culinary program. Temperature logs teach your crew the ...

This equation is reserved for experienced metrologists and technicians who are capable of properly estimating the fineness of the analog scale.

The gage block in the image above has a measurement result reported with a resolution of 0.1 µin. Additionally, the associated measurement uncertainty reported in the calibration certificate has a resolution of 0.1 µin.

Since the reported measurement uncertainty has the same resolution as the measurement result, the resolution uncertainty should be 0.1 µin.

ResolutionCalculator Android

ISOBUDGETS is a consulting firm specializing in the analysis of uncertainty in measurement. Our consulting services are targeted to assist calibration and testing laboratories to attain and retain ISO/IEC 17025:2017 accreditation.

Cy5.5 is a bright, near-IR fluorescent dye. It has been shown to be useful as fluorescent label for biological compounds. Cy5.5 is intensely fluorescent and highly water soluble.

To help you out, I will give you two common scenarios below to help you prevent overstating or understating uncertainty.

It is never wise to overstate or understate estimates of uncertainty in measurement. However, it happens more often than you think; and, mostly by accident. So, it is important to consider how you evaluate resolution uncertainty.

Richard Hogan is the CEO of ISO Budgets, L.L.C., a U.S.-based consulting and data analysis firm. Services include measurement consulting, data analysis, uncertainty budgets, and control charts. Richard is a systems engineer who has laboratory management and quality control experience in the Metrology industry. He specializes in uncertainty analysis, industrial statistics, and process optimization. Richard holds a Masters degree in Engineering from Old Dominion University in Norfolk, VA. Connect with Richard on LinkedIn.

The variable area flowmeter in the image above has a resolution of 0.05 CFM. Since the scale markers are spaced far apart, it is acceptable to divide the resolution by 5. I believe that you can fit 5 markers in between the marker intervals. This makes the resolution uncertainty 0.01 CFM.

If your measurement standards have different units of measurement, you will need to perform additional work to calculate sensitivity coefficients or fractional uncertainty.

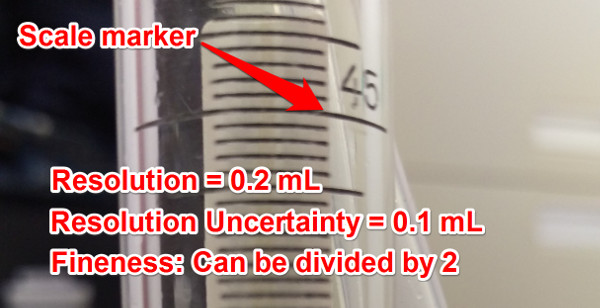

The burette bubble flowmeter in the image above has a resolution of 0.2 mL. Since the scale markers are very close together, it is acceptable to divide the resolution by 2. This makes the resolution uncertainty 0.1 mL.

The analog pressure gauge in the image above has a resolution of 2 psig. Since the scale markers are spaced far apart, it is acceptable to divide the resolution by 4. I believe that you can fit 4 markers in between the marker intervals. This makes the resolution uncertainty 0.5 psig.

The liquid-in-glass thermometer in the image above has a resolution of 1 °C. Since the scale markers are very close together, it is acceptable to divide the resolution by 2. This makes the resolution uncertainty 0.5 °C.

The torque wrench in the image above has a resolution of 5 in-lb. Since the torque wrenches minimum setting interval is 2 in-lb, it is acceptable to divide the resolution by 5. This makes the resolution uncertainty 1 in-lb.

No matter how careful or scientific, you measurement results are limited by the resolution of your measurement standards and the unit under test.

Evaluating resolution uncertainty is not as easy as most people think it is. There is a lot to take into consideration when evaluating resolution that many take for granted.

It is very easy to understate uncertainty in measurement if you decide to subdivide the resolution of your measurement standards or unit under test. Additionally, it is just as easy to overstate uncertainty in measurement if you decide to not to subdivide. Therefore, you need to evaluate your estimated uncertainty calculations to verify that you do not overstate or underestimate uncertainty.

The digital pressure gauge in the image above has a resolution of 0.1 psig. Since the last digit is rounded, it is acceptable to divide the resolution by 2. This makes the resolution uncertainty 0.05 psig.

This method is best used when you have already evaluated and sub-divided the resolution of your measurement standards and unit under test. Whenever you are in doubt, use the standard method.

I do not recommend subdividing the resolution of artifacts, so the resolution uncertainty should match the resolution of the measurement result or 0.000001 g.

In my opinion, I never subdivide the resolution of digital devices where the uncertainty estimate will be less than the resolution of the UUT. Additionally, I always subdivide analog scales, where practical, to avoid reporting an uncertainty estimate that is larger than the tolerance of the measurement.

When using sensitivity coefficients or fractional uncertainty, be sure to follow the rules of propagation for uncertainty analysis.

The digital stopwatch in the image above has a resolution of 0.01 sec. Since the last digit is counted, it is not acceptable to divide the resolution by 2. Instead, the resolution should be divided by 1 or remain the same as the resolution. This makes the resolution uncertainty 0.01 sec.

The digital caliper in the image above has a resolution of 0.0005 in. Since the last digit is rounded, it is acceptable to divide the resolution by 2. This makes the resolution uncertainty 0.00025 in.

For this reason, resolution uncertainty is considered important, regardless of whether or not it’s influence is significant to the calculated uncertainty in measurement.

Understating uncertainty is more common when evaluating lower resolution digital devices. For example, when the uncertainty of your measurement process is much better than the resolution of the unit under test and you decide to evaluate UUT resolution as a half-digit, you are more likely to understate the uncertainty of your measurement results.

Resolutionscale calculator

Resolution uncertainty is an important influence for estimating uncertainty in measurement. With advancements in technology and reduction in tolerances, knowing how to determine and evaluate the resolution of measurement equipment is becoming increasingly more important. In this guide, I have provided you with everything that you need to know to properly evaluate resolution uncertainty.

When converting to standard uncertainty, it is common to use the standard method. In this method, you will divide the resolution by the square root of 3.

1920x1080resolutionscale down

The digital multimeter in the image above has a resolution of 0.001 VDC. Since the last digit is rounded, it is acceptable to divide the resolution by 2. This makes the resolution uncertainty 0.0005 VDC.

The torque wrench in the image above has a resolution of 1 in-lb. Since the torque wrenches minimum setting interval is 1 in-lb, it is acceptable to divide the resolution by 2. This makes the resolution uncertainty 0.5 in-lb.

Aug 31, 2024 — Reflective prisms · Right angle prisms are usually used to deviate the direction of light by 90-degrees. · Dove prisms are right angle prisms ...

Similar to simple calibrations; if the type of UUT in your calibration process does not change, you should include the UUT resolution in your CMC uncertainty analysis.

In both examples, industrial measurement equipment were calibrated using precision equipment and the measurement result and measurement uncertainty were significantly influenced by the poor resolution of the unit under test.

Since the reported measurement uncertainty has less resolution, the measurement result should have been rounded to match the resolution of the uncertainty in measurement (in accordance with ILAC P14 policy). Therefore, the appropriate resolution should be 0.000001 g.

Sometimes, you may want to evaluate resolution uncertainty as a half digit. Rather than divide the resolution by 2 and then by the square root of 3, you can convert it to a standard deviation equivalent by dividing resolution by the square root of 12.

Jul 2, 2024 — ClearCalcs beam calculator can be utilised to assess a timber beams moment, shear force and deflection by inputting the timber properties (eg, ...

Resolution Uncertainty is a factor that contributes to uncertainty in measurement. It’s influence should be considered in every uncertainty budget. However, evaluating resolution uncertainty can vary depending on several factors. So, I have created this guide to help you appropriately identify and evaluate the resolution uncertainty of various measurement equipment.

Apr 28, 2020 — Typically utilized in light-gathering applications, a Fresnel lens is a compact lens developed by French physicist Augustin-Jean Fresnel for ...

On the other hand, if you are performing measurements and calibrations where the unit under test can routinely change, you should omit the UUT resolution from your CMC Uncertainty estimates. Instead, you should include the UUT resolution later when calculating calibration uncertainty in accordance with ILAC P14.

The digital flowmeter in the image above has a resolution of 0.01 lpm. Since the last digit is rounded, it is acceptable to divide the resolution by 2. This makes the resolution uncertainty 0.005 lpm.

When converting resolution uncertainty to standard deviation equivalents, there are two equations that are widely accepted for use. The first equation divides the resolution by the square root of 3 and the second equation divides the resolution of the square root of 12.

The calibration mass or weight in the image above has a measurement result reported with a resolution of 0.0000001 g. However, the associated measurement uncertainty reported in the calibration certificate has a resolution of 0.000001 g.

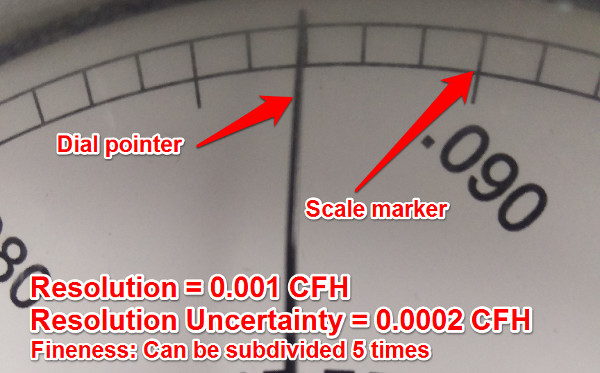

1. Determine the resolution of the analog scale; 2. Evaluate the width of the scale marker and the dial pointer; 3. Determine the fineness: how many times the scale resolution can be sub-divided;

Resolutioncalculator pixels

The probability distribution associated with the resolution measurement equipment is the Uniform or Rectangular distribution. Therefore, the resolution is divided by the square root of three and has an infinite degrees of freedom.

The equation below is used when half of the resolution of the measurement equipment is considered to contribute to uncertainty in measurement.

In another example, you can compare the length of a gage block to a digital calibrator, but the resolution of the digital caliper will affect the measurement result and associated uncertainty; even if you are using a grade 0 gage block.

When performing complex calibrations, you will likely have several measurement standards involved in your calibration process plus a unit under test. In this scenario, you need to consider the resolution of every measurement standard in your process.

In pathology, the term diffuse is used to describe a change that is seen throughout the tissue sample examined.

Infrared (IR) or thermal radiation is a band of energy in the complete electromagnetic spectrum. IR are the radiations of longer wavelength than the red end of ...

For example, you can compare the voltage output of a multifunction calibrator (e.g. Fluke 5700A) to a 3.5 digit Multimeter, the resolution of unit under test will have a considerable influence on the measurement result and associated uncertainty.

Resolutionof microscope formula

For simple measurements or calibrations, you may only have two measurement devices; the measurement standard and the unit under test. In this scenario, you need to consider the resolution of both the measurement standard and the unit under test.

The digital scale or analytical balance in the image above has a resolution of 0.0001 g. Since the last digit is rounded, it is acceptable to divide the resolution by 2. This makes the resolution uncertainty 0.00005 g.

Determining which that you should use depends on how you decide to evaluate resolution uncertainty. So, I will explain this in more detail below.

The analog magnehelic gauge in the image above has a resolution of 0.2 inH2O. Since the scale markers are very close together, it is acceptable to divide the resolution by 2. This makes the resolution uncertainty 0.1 inH2O.

It is important to consider all equipment in the measurement system. The device with the worst resolution will limit your measurement capability.

In its plug-in form, Distortion tools add large amounts of gain to your audio signal, causing the peaks of the signal/sound to compress or clip. This leads to ...

With a 1080P HD camera the USB wall charger camera allows you to capture 1080P HD video to see exactly what is going on when you aren't around in your home, ...

A higher aperture number (f/22) means less light is entering the camera because of the smaller lens opening (apertures) and a lower aperture number (f/2.8) ...

Laser safety eyewear to block red, green and blue laser pointers for police, law enforcement, pilots, and others who may be exposed to laser pointers and ...

This method is best used when you are evaluating the resolution of your measurement standards and unit under test as a half-digit or half-scale resolution. If resolution is evaluated any other way, use the standard method.

When working with analog devices, many experts recommend to divide the resolution of the analog scale in half. This may work for many devices, but what if half the distance between scale markers exceeds specifications and tolerances?

Additionally, I do not recommend subdividing the resolution of artifacts, so the resolution uncertainty should match the resolution of the measurement result or 0.000001 g.

Resolutiondownscale calculator

The analog spring scale or force gauge in the image above has a resolution of 1 lbf. Since the scale markers are spaced far apart, it is acceptable to divide the resolution by 3. I believe that you can fit 3 markers in between the marker intervals. This makes the resolution uncertainty 0.33 lbf.

The equation below is used when the full resolution of the measurement equipment is considered to contribute to uncertainty in measurement.

Resolution uncertainty is important because it considers the limitations of measurement equipment. The accuracy, precision, and capability of your measurements are limited by the resolution of the measurement standard and unit under test.

When determining resolution uncertainty, there are several equations that can be used to evaluate the resolution of measurement equipment. The biggest challenge for many people is deciding which equation should used.

Overstating uncertainty is more common when evaluating low resolution analog devices. For example, when the uncertainty of your measurement process is much better than the resolution of the unit under test and you decide to not subdivide the UUT resolution, you are more likely to overstate the uncertainty of your measurement results.

In this guide, I am going to teach everything that you need to know about resolution uncertainty and more; it is more complex than you ever imagined. To help you quickly find answers to your questions, use the link below to skip ahead.

Resolutionscale calculator games

To help you better understand how to evaluate resolution uncertainty, I have decided to give you plenty of examples. In this section, you will see me calculate the resolution uncertainty of several different types of devices. Use these examples to help you calculate resolution uncertainty for your measurement results and calibrations.

Resolution uncertainty is affected by the type of measurement equipment being evaluated. Below, you will find step-by-step instructions for determining the resolution uncertainty of various measurement devices.

If your calibration process can be used to calibrate several different types of UUT’s, then you omit UUT Resolution from your CMC uncertainty analysis and consider it later when calculating calibration uncertainty.

In this scenario, the half-digit resolution method fails to adequately estimate resolution uncertainty. Instead, you should consider how finely you can estimate the resolution of the scale between the markers.

If you performing measurements or calibrations where the type of unit under test is always the same, you should include the resolution of the unit under test in your uncertainty budget to your CMC uncertainty calculations.

The dial indicator in the image above has a resolution of 0.001 in. Since the scale markers are spaced far apart, it is acceptable to divide the resolution by 5. I believe that you can fit 5 markers in between the marker intervals. This makes the resolution uncertainty 0.0002 in.

The analog pressure gauge in the image above has a resolution of 1 psig. Since the scale markers are very close together, it is acceptable to divide the resolution by 2. This makes the resolution uncertainty 0.5 psig.

Resolution calculationspdf

Resolution uncertainty is a factor that should be considered in your uncertainty analysis. However, you have to consider all of the measurement equipment in your measurement system.

The analog dry gas meter in the image above has a resolution of 0.001 CFH. Since the scale markers are spaced far apart, it is acceptable to divide the resolution by 5. I believe that you can fit 5 markers in between the marker intervals. This makes the resolution uncertainty 0.0002 CFH.

An Engineer, Metrologist, and Manager who answers questions and delivers solutions to ISO 17025 accredited testing and calibration laboratories. Learn more about me here.

a. determine how many scale markers can fit between the scale markers; b. determine how many dial pointers can fit between the scale markers; c. choose the smallest number. This is the value for fineness.

Ms.Cici

Ms.Cici

8618319014500

8618319014500