Why Is My Field of View (FOV) Moving While Focusing ... - lens fov

The next level of condenser sophistication is split between the aplanatic and achromatic condensers that are corrected exclusively for either spherical (aplanatic) or chromatic (achromatic) optical aberrations. Achromatic condensers usually contain three to four lens elements and are corrected in two wavelengths (red and blue) for chromatic aberration. The achromatic condenser usually contains four lens elements and has a numerical aperture ranging from 0.9 to 1.4. This condenser design is useful for both routine and critical laboratory analysis with "dry" or oil immersion objectives and also for black and white or color photomicrography and digital imaging. The highest level of correction for optical aberration is incorporated in the aplanatic-achromatic condenser. This condenser is well corrected for both chromatic and spherical aberrations and is the condenser of choice for use in critical color imaging with white light. A typical aplanatic-achromatic condenser features eight internal lens elements cemented into two doublets and four single lenses.

Modern microscopes feature vastly improved plan-corrected objectives in which the primary image has much less curvature of field than older objectives. In addition, most microscopes now feature much wider body tubes that have greatly increased the size of intermediate images. To address these new features, manufacturers now produce wide-eyefield eyepieces that increase the viewable area of the specimen by as much as 40 percent. Because the strategies of eyepiece-objective correction techniques vary from manufacturer to manufacturer, it is very important to use only eyepieces recommended by a specific manufacturer for use with their objectives. Additionally, most eyepieces on research-level microscopes have a focusing ring, which makes it possible to precisely focus on reticles that are mounted into the space where the intermediate image resides. The focusing ring also makes it possible to establish a condition on the microscope that is referred to as being parfocal, where operators with different eyesights can configure the microscope in such a manner that the images produced by the objective remain in focus when a new objective is inserted into the optical path.

This scaling gives adjusted LIDT values of 0.08 J/cm2 for the reflective filter and 14 J/cm2 for the absorptive filter. In this case, the absorptive filter is the best choice in order to avoid optical damage.

The following is a general overview of how laser induced damage thresholds are measured and how the values may be utilized in determining the appropriateness of an optic for a given application. When choosing optics, it is important to understand the Laser Induced Damage Threshold (LIDT) of the optics being used. The LIDT for an optic greatly depends on the type of laser you are using. Continuous wave (CW) lasers typically cause damage from thermal effects (absorption either in the coating or in the substrate). Pulsed lasers, on the other hand, often strip electrons from the lattice structure of an optic before causing thermal damage. Note that the guideline presented here assumes room temperature operation and optics in new condition (i.e., within scratch-dig spec, surface free of contamination, etc.). Because dust or other particles on the surface of an optic can cause damage at lower thresholds, we recommend keeping surfaces clean and free of debris. For more information on cleaning optics, please see our Optics Cleaning tutorial.

Aperture adjustment and proper focusing of the condenser (with regard to height in relation to the objective) are of critical importance in realizing the full potential of the objective. Specifically, appropriate use of the adjustable aperture iris diaphragm (incorporated into the condenser or just below it) is of significant importance in securing correct illumination, contrast, and depth of field. The opening size of this iris diaphragm controls the angles of illuminating wavefronts (and thus the aperture size) that bathe the specimen. Condenser height is controlled by a rack and pinion gear system that allows the condenser focus to be adjusted for proper illumination of the specimen. Correct positioning of the condenser with relation to the cone of illumination and focus (a step in establishing Köhler illumination) is critical to quantitative microscopy and to ensure the best digital images.

When an optic is damaged by a continuous wave (CW) laser, it is usually due to the melting of the surface as a result of absorbing the laser's energy or damage to the optical coating (antireflection) [1]. Pulsed lasers with pulse lengths longer than 1 µs can be treated as CW lasers for LIDT discussions.

Research-level microscopes also contain one of several light-conditioning devices that are often positioned between the illuminator and condenser, and a complementary detector or filtering device that is inserted between the objective and the eyepiece or camera. The conditioning device(s) and detector work together to modify image contrast as a function of spatial frequency, phase, polarization, absorption, fluorescence, off-axis illumination, and/or other properties of the specimen and illumination technique. Even without the addition of specific devices to condition illumination and filter image-forming waves, some degree of natural filtering occurs with even the most basic microscope configuration.

Stagemicroscope function

The circular polarizers are coated on each air-to-glass interface with an antireflective coating for either 350 - 700 nm (Thorlabs' -A coating), 650 - 1100 nm (Thorlabs' -B coating), or 1050 - 1700 nm (Thorlabs' -C coating). These high-performance multilayer AR coatings have an average reflectance of less than 0.5% (per surface) across the specified wavelength ranges.

If this relatively long-pulse laser emits a Gaussian 12.7 mm diameter beam (1/e2) at 980 nm, then the resulting output has a linear power density of 5.9 W/cm and an energy density of 1.2 x 10-4 J/cm2 per pulse. This can be compared to the LIDT values for a WPQ10E-980 polymer zero-order quarter-wave plate, which are 5 W/cm for CW radiation at 810 nm and 5 J/cm2 for a 10 ns pulse at 810 nm. As before, the CW LIDT of the optic scales linearly with the laser wavelength, resulting in an adjusted CW value of 6 W/cm at 980 nm. On the other hand, the pulsed LIDT scales with the square root of the laser wavelength and the square root of the pulse duration, resulting in an adjusted value of 55 J/cm2 for a 1 µs pulse at 980 nm. The pulsed LIDT of the optic is significantly greater than the energy density of the laser pulse, so individual pulses will not damage the wave plate. However, the large average linear power density of the laser system may cause thermal damage to the optic, much like a high-power CW beam.

Simple eyepieces such as the Huygenian and Ramsden and their achromatized counterparts will not correct for residual chromatic difference of magnification in the intermediate image, especially when used in combination with high magnification achromatic objectives as well as any fluorite or apochromatic objectives. To remedy this, manufacturers produce compensating eyepieces that introduce an equal, but opposite, chromatic error in the lens elements. Compensating eyepieces may be either of the positive or negative type, and must be used at all magnifications with fluorite, apochromatic and all variations of plan objectives (they can also be used to advantage with achromatic objectives of 40x and higher). In recent years, modern microscope objectives have their correction for chromatic difference of magnification either built into the objectives themselves or corrected in the tube lens.

In recent years, SVL has introduced more SWIR wavelengths – ranging from 1050 to 1550 nm – than any other machine vision lighting company. We've also led the ...

These polarizers define the direction of circular polarization as viewed from the light source looking along the optical axis in the direction of propagation. "Right-handed" circular polarization refers to the clockwise rotation of the electric field over time, at a fixed point on the optical axis. See the image to the right for a visual representation.

The calculation above assumes a uniform beam intensity profile. You must now consider hotspots in the beam or other non-uniform intensity profiles and roughly calculate a maximum power density. For reference, a Gaussian beam typically has a maximum power density that is twice that of the uniform beam (see lower right).

When the objective is changed, for example from a 10x to 20x, the aperture diaphragm of the condenser must also be adjusted to provide a new light cone that matches the numerical aperture of the new objective. This is done by turning the knurled knob or lever that controls the condenser aperture diaphragm. There is a small yellow or white dot, arrow, or index mark located on the condenser that indicates the relative size of the aperture when compared to the linear gradation on the condenser housing. Many manufacturers will synchronize this gradation to correspond to the approximate numerical aperture of the condenser. For example, if the microscopist has selected a 10x objective of numerical aperture 0.25, then the arrow would be placed next the value 0.18-0.20 (about 80 percent of the objective numerical aperture) on the gradation inscribed on the condenser housing.

Alternatively, these polarizers can convert left-handed circularly polarized light into linearly polarized light. The arrow marking on the edge of the optic points in the direction of transmission for this application. If right-handed circularly polarized light is incident on the polarizer in this direction, the transmission through the optic will be zero.

Thorlabs' LIDT testing is done in compliance with ISO/DIS 11254 and ISO 21254 specifications.First, a low-power/energy beam is directed to the optic under test. The optic is exposed in 10 locations to this laser beam for 30 seconds (CW) or for a number of pulses (pulse repetition frequency specified). After exposure, the optic is examined by a microscope (~100X magnification) for any visible damage. The number of locations that are damaged at a particular power/energy level is recorded. Next, the power/energy is either increased or decreased and the optic is exposed at 10 new locations. This process is repeated until damage is observed. The damage threshold is then assigned to be the highest power/energy that the optic can withstand without causing damage. A histogram such as that below represents the testing of one BB1-E02 mirror.

The more highly corrected fluorite and plan-fluorite objectives have better color correction (at least three wavelengths) and feature flat fields (plan versions) in viewfields up to 26 millimeters in diameter. Due to the use of more advanced specialized glasses, fluorites are able to transmit ultraviolet wavelengths with high efficiency. Fluorite objectives are available for all contrast-enhancing modes, and special high-quality versions are available for polarized light and DIC. The apochromat objectives are the best performers and so are produced at the highest numerical aperture with color correction for at least four wavelengths. Plan versions reduce transmission efficiency, but produce spectacular images with a high degree of field flatness over the entire viewfield. As the need for specialized objectives grows with advances in technology, new apochromats are being designed to push the envelope with regards to color correction (360 to 700 nanometers or more), numerical aperture (up to 1.49), working distance, and suitability for various immersion media.

In order to illustrate the process of determining whether a given laser system will damage an optic, a number of example calculations of laser induced damage threshold are given below. For assistance with performing similar calculations, we provide a spreadsheet calculator that can be downloaded by clicking the button to the right. To use the calculator, enter the specified LIDT value of the optic under consideration and the relevant parameters of your laser system in the green boxes. The spreadsheet will then calculate a linear power density for CW and pulsed systems, as well as an energy density value for pulsed systems. These values are used to calculate adjusted, scaled LIDT values for the optics based on accepted scaling laws. This calculator assumes a Gaussian beam profile, so a correction factor must be introduced for other beam shapes (uniform, etc.). The LIDT scaling laws are determined from empirical relationships; their accuracy is not guaranteed. Remember that absorption by optics or coatings can significantly reduce LIDT in some spectral regions. These LIDT values are not valid for ultrashort pulses less than one nanosecond in duration.

Alternatively, these polarizers can convert right-handed circularly polarized light into linearly polarized light. The arrow marking on the edge of the optic points in the direction of transmission for this application. If left-handed circularly polarized light is incident on the polarizer in this direction, the transmission through the optic will be zero.

Now compare the maximum power density to that which is specified as the LIDT for the optic. If the optic was tested at a wavelength other than your operating wavelength, the damage threshold must be scaled appropriately. A good rule of thumb is that the damage threshold has a linear relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 10 W/cm at 1310 nm scales to 5 W/cm at 655 nm):

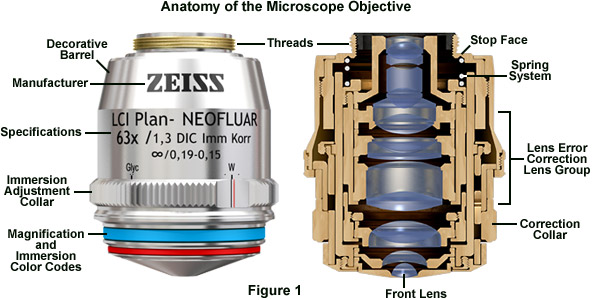

Most of the high-performance objectives feature spring mounts (see Figure 1) to protect the specimen, and many of the immersion objectives have nosepieces that can be snapped into the top position of their spring mount to enable the easy application of immersion fluids. The glass selected for objective fabrication must have suitable refractive index and dispersion, homogeneity, absence of strain, high chemical resistance, low thermal expansion, resistance to climatic changes, and high light transmission through the near-ultraviolet, visible, and near-infrared portions of the spectrum. In terms of how the various correction factors for objectives are categorized, the achromats have good color correction in two wavelengths, feature relatively flat fields in the center of the image, but require refocusing to observe details in the peripheral areas. Achromats are produced in versions designed for polarized light and phase contrast, but not fluorescence or differential interference contrast (DIC). Plan and epi-plan objectives are improved achromat versions with excellent flatness of field up to diameters of 24 millimeters or more. In addition, reflected light achromat objectives exhibit excellent contrast and a variety of working distances. The specifications required to identify objectives (see Figure 4) are usually inscribed on the decorative barrel protecting the internal lens elements.

The pulse length must now be compensated for. The longer the pulse duration, the more energy the optic can handle. For pulse widths between 1 - 100 ns, an approximation is as follows:

Our engineers work with our customers to discuss the specifications and other design aspects of a customized circular polarizer. We analyze the design for quality and feasibility to ensure the customized products are manufactured to meet the highest standards in a timely manner. For more information about ordering a customized polymer wave plate, please contact Technical Support.

The simplest negative eyepiece design, often termed the Huygenian eye-piece, is found on most teaching and laboratory microscopes fitted with achromatic objectives. Although the Huygenian eye and field lenses are not well corrected, their aberrations tend to cancel each other. More highly corrected negative eyepieces have two or three lens elements cemented and combined together to make the eye lens. If an unknown eyepiece carries only the magnification inscribed on the housing, it is most likely a Huygenian eyepiece, best suited for use with achromatic objectives of 5x to 40x magnification. The other common eyepiece is the positive eyepiece with a diaphragm below its lenses, commonly known as the Ramsden eyepiece. This eyepiece has an eye lens and field lens that are also plano-convex, but the field lens is mounted with the curved surface facing towards the eye lens. The front focal plane of this eyepiece lies just below the field lens, at the level of the eyepiece diaphragm, making this eyepiece readily adaptable for mounting reticules.

Thank you for your time and business. EDMUND SCIENTIFIC MICROSCOPE WF10X EYEPIECE. Previously used at a local university. Sold as is as shown in pictures below ...

However, the maximum power density of a Gaussian beam is about twice the maximum power density of a uniform beam, as shown in the graph to the right. Therefore, a more accurate determination of the maximum linear power density of the system is 1 W/cm.

Custom Size and Mounting OptionsWe offer unmounted Ø1" circular polarizers from stock. Customized polarizers are available in sizes from Ø0.5" to Ø2" and can be ordered either mounted or unmounted.

Microscope objectives are by far the most complex assemblies in the optical train. In contrast to the condenser and eyepieces, which contain between two and eight lenses, highly corrected objectives with numerical apertures above 1.0 can feature up to 15 or more lens elements and groups (see Figure 1). Objectives are fabricated with differing degrees of optical correction for both monochromatic (spherical, astigmatism, coma, distortion) and polychromatic aberrations, as well as field size and flatness, wavelength transmission band, birefringence, freedom from fluorescence and a variety of other factors that contribute to background noise. The two main criteria in objective manufacture are the elimination of chromatic errors and the flatness of the intermediate image that when perfectly corrected, provide an image with edge-to-edge sharpness, even with large fields of view. Depending upon the degree of correction, objectives are generally classified as achromats, fluorites, and apochromats, with a plan designation added to lenses with low curvature of field. Furthermore, objectives can be specifically classified into transmitted light and reflected light versions. The transmitted light versions popular in biological applications are usually designed for use with coverslips (in most cases, 170 micrometers in thickness). Reflected light (often termed Epi) objectives feature specially coated glass surfaces (antireflective coating) to avoid reflections in the optics when examining specimens lacking a coverslip. In fact, these objectives are specifically designed to be used on specimens without a coverslip.

Use this formula to calculate the Adjusted LIDT for an optic based on your pulse length. If your maximum energy density is less than this adjusted LIDT maximum energy density, then the optic should be suitable for your application. Keep in mind that this calculation is only used for pulses between 10-9 s and 10-7 s. For pulses between 10-7 s and 10-4 s, the CW LIDT must also be checked before deeming the optic appropriate for your application.

High power objectivemicroscope function

LV Dall'Armi · 2023 · 25 — The circular polarization of gravitational waves is a powerful observable to test parity violation in gravity and to distinguish between the primordial or the ...

To use the lens view, press Ctrl + Alt + L. To cycle between the views, press Ctrl + Alt + M. You can use this to quickly compare the views and see which ...

Now compare the maximum energy density to that which is specified as the LIDT for the optic. If the optic was tested at a wavelength other than your operating wavelength, the damage threshold must be scaled appropriately [3]. A good rule of thumb is that the damage threshold has an inverse square root relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 1 J/cm2 at 1064 nm scales to 0.7 J/cm2 at 532 nm):

Condensermicroscope function

LIDT in linear power density vs. pulse length and spot size. For long pulses to CW, linear power density becomes a constant with spot size. This graph was obtained from [1].

CW Laser ExampleSuppose that a CW laser system at 1319 nm produces a 0.5 W Gaussian beam that has a 1/e2 diameter of 10 mm. A naive calculation of the average linear power density of this beam would yield a value of 0.5 W/cm, given by the total power divided by the beam diameter:

As previously stated, pulsed lasers typically induce a different type of damage to the optic than CW lasers. Pulsed lasers often do not heat the optic enough to damage it; instead, pulsed lasers produce strong electric fields capable of inducing dielectric breakdown in the material. Unfortunately, it can be very difficult to compare the LIDT specification of an optic to your laser. There are multiple regimes in which a pulsed laser can damage an optic and this is based on the laser's pulse length. The highlighted columns in the table below outline the relevant pulse lengths for our specified LIDT values.

Compensating eyepieces play a crucial role in helping to eliminate residual chromatic aberrations inherent in the design of highly corrected objectives on older finite tube length microscopes. Hence, it is preferable that the microscopist uses the compensating eyepieces designed by a particular manufacturer to accompany that manufacturer's higher-corrected objectives. Use of an incorrect eyepiece with an apochromatic objective designed for an older finite (160 or 170 millimeter) tube length application results in dramatically increased contrast with red fringes on the outer diameters and blue fringes on the inner diameters of specimen detail. Additional problems arise from a limited flatness of the viewfield in simple eyepieces, even those corrected with eye-lens doublets. More advanced eyepiece designs resulted in the Periplan eyepiece design (see Figure 3). This eyepiece contains seven lens elements that are cemented into a single doublet, a single triplet, and two individual lenses. Design improvements in periplan eyepieces lead to better correction for residual lateral chromatic aberration, increased flatness of field, and a general overall better performance when used with higher power objectives.

Beam diameter is also important to know when comparing damage thresholds. While the LIDT, when expressed in units of J/cm², scales independently of spot size; large beam sizes are more likely to illuminate a larger number of defects which can lead to greater variances in the LIDT [4]. For data presented here, a <1 mm beam size was used to measure the LIDT. For beams sizes greater than 5 mm, the LIDT (J/cm2) will not scale independently of beam diameter due to the larger size beam exposing more defects.

A single lens has two precisely regular opposite surfaces; either both surfaces are curved or one is curved and one is plane. Lenses may be classified according ...

Stage clipsmicroscope function

According to the test, the damage threshold of the mirror was 2.00 J/cm2 (532 nm, 10 ns pulse, 10 Hz, Ø0.803 mm). Please keep in mind that these tests are performed on clean optics, as dirt and contamination can significantly lower the damage threshold of a component. While the test results are only representative of one coating run, Thorlabs specifies damage threshold values that account for coating variances.

Function of an Eyepiece ... An Eyepiece isvery unusual. It is one of very few optical devices which has its exit pupil outside the lens cluster. It takes some ...

Please note that we have a buffer built in between the specified damage thresholds online and the tests which we have done, which accommodates variation between batches. Upon request, we can provide individual test information and a testing certificate. Contact Tech Support for more information.

An AC127-030-C achromatic doublet lens has a specified CW LIDT of 350 W/cm, as tested at 1550 nm. CW damage threshold values typically scale directly with the wavelength of the laser source, so this yields an adjusted LIDT value:

Pulsed Microsecond Laser ExampleConsider a laser system that produces 1 µs pulses, each containing 150 µJ of energy at a repetition rate of 50 kHz, resulting in a relatively high duty cycle of 5%. This system falls somewhere between the regimes of CW and pulsed laser induced damage, and could potentially damage an optic by mechanisms associated with either regime. As a result, both CW and pulsed LIDT values must be compared to the properties of the laser system to ensure safe operation.

This adjustment factor results in LIDT values of 0.45 J/cm2 for the BB1-E01 broadband mirror and 1.6 J/cm2 for the Nd:YAG laser line mirror, which are to be compared with the 0.7 J/cm2 maximum energy density of the beam. While the broadband mirror would likely be damaged by the laser, the more specialized laser line mirror is appropriate for use with this system.

When pulse lengths are between 1 ns and 1 µs, laser-induced damage can occur either because of absorption or a dielectric breakdown (therefore, a user must check both CW and pulsed LIDT). Absorption is either due to an intrinsic property of the optic or due to surface irregularities; thus LIDT values are only valid for optics meeting or exceeding the surface quality specifications given by a manufacturer. While many optics can handle high power CW lasers, cemented (e.g., achromatic doublets) or highly absorptive (e.g., ND filters) optics tend to have lower CW damage thresholds. These lower thresholds are due to absorption or scattering in the cement or metal coating.

[1] R. M. Wood, Optics and Laser Tech. 29, 517 (1998).[2] Roger M. Wood, Laser-Induced Damage of Optical Materials (Institute of Physics Publishing, Philadelphia, PA, 2003).[3] C. W. Carr et al., Phys. Rev. Lett. 91, 127402 (2003).[4] N. Bloembergen, Appl. Opt. 12, 661 (1973).

On upright microscopes, the condenser is located beneath the stage and serves to gather wavefronts from the microscope light source and concentrate them into a cone of light that illuminates the specimen with uniform intensity over the entire viewfield. Inverted (tissue culture style) microscopes mount the condenser above the stage and specimen on a frame pillar. It is critical that the condenser light cone be properly adjusted to optimize the intensity and angle of light entering the objective front lens. Each time the objective is changed, a corresponding adjustment must be performed on the condenser to provide the proper light cone to match the light cone (numerical aperture) of the new objective. A simple two-lens Abbe condenser is illustrated in Figure 2. In this figure, light from the microscope illumination source passes through the condenser aperture diaphragm, located at the base of the condenser, and is concentrated by internal lens elements, which then project light through the specimen in parallel bundles from every azimuth. The size and numerical aperture of the light cone is determined by adjustment of the aperture diaphragm. After passing through the specimen, the light diverges into an inverted cone with the proper angle to fill the front lens of the objective.

Condensers are divided primarily into classifications of imaging modality (such as brightfield, darkfield, and phase contrast), but also according to their degree of optical correction. There are four principle types of condensers with respect to correction of optical aberrations, as listed in Table 1. The simplest and least corrected (also the least expensive) condenser is the Abbe condenser that can have a numerical aperture up to 1.4 in the best models with three or more internal lens elements. Although the Abbe condenser is capable of passing bright light, it is not corrected for either chromatic or spherical optical aberrations. A typical Abbe condenser is illustrated in Figure 2. In its simplest form, the Abbe condenser has two optical lens elements that produce an image of the illuminated field diaphragm that is not sharp and is surrounded by blue and red color at the edges, characteristic of chromatic aberration.

Aug 23, 2022 — Magnification by Spherical Lenses is a measure of how large or small in size the image of an object is, compared to that of the object.

Pulses shorter than 10-9 s cannot be compared to our specified LIDT values with much reliability. In this ultra-short-pulse regime various mechanics, such as multiphoton-avalanche ionization, take over as the predominate damage mechanism [2]. In contrast, pulses between 10-7 s and 10-4 s may cause damage to an optic either because of dielectric breakdown or thermal effects. This means that both CW and pulsed damage thresholds must be compared to the laser beam to determine whether the optic is suitable for your application.

The energy density of your beam should be calculated in terms of J/cm2. The graph to the right shows why expressing the LIDT as an energy density provides the best metric for short pulse sources. In this regime, the LIDT given as an energy density can be applied to any beam diameter; one does not need to compute an adjusted LIDT to adjust for changes in spot size. This calculation assumes a uniform beam intensity profile. You must now adjust this energy density to account for hotspots or other nonuniform intensity profiles and roughly calculate a maximum energy density. For reference a Gaussian beam typically has a maximum energy density that is twice that of the 1/e2 beam.

Thorlabs offers a large variety of circular polarizers with operating wavelengths from 405 nm to 1550 nm. In addition, we also offer OEM and customized circular polarizers upon request. The design wavelength, coating, mechanical housing, and dimensions can be customized to meet unique application needs.

As described above, the maximum energy density of a Gaussian beam is about twice the average energy density. So, the maximum energy density of this beam is ~0.7 J/cm2.

Right-handed circular polarizers will convert a beam with an arbitrary polarization state into a right-handed circularly polarized beam, provided that the input beam is not polarized perpendicular to the linear polarizing film inside. The input surface and transmission axis of the polarizing film is marked by an arrow on the edge of the circular polarizer.

Engravings found on the condenser housing include its type (achromatic, aplanatic, etc.), the numerical aperture, and a graded scale that indicates the approximate adjustment (size) of the aperture diaphragm. Condensers with numerical apertures above 0.95 perform best when a drop of oil is applied to their upper lens in contact with the undersurface of the specimen slide. This ensures that oblique light rays emanating from the condenser are not reflected from underneath the slide, but are directed into the specimen. In practice, this can become tedious and is not commonly done in routine microscopy, but is essential when working at high resolutions and for accurate imaging using high-power (and numerical aperture) objectives.

The adjusted LIDT value of 350 W/cm x (1319 nm / 1550 nm) = 298 W/cm is significantly higher than the calculated maximum linear power density of the laser system, so it would be safe to use this doublet lens for this application.

The energy density of the beam can be compared to the LIDT values of 1 J/cm2 and 3.5 J/cm2 for a BB1-E01 broadband dielectric mirror and an NB1-K08 Nd:YAG laser line mirror, respectively. Both of these LIDT values, while measured at 355 nm, were determined with a 10 ns pulsed laser at 10 Hz. Therefore, an adjustment must be applied for the shorter pulse duration of the system under consideration. As described on the previous tab, LIDT values in the nanosecond pulse regime scale with the square root of the laser pulse duration:

Low power objectivemicroscope function

Erin E. Wilson and Michael W. Davidson - National High Magnetic Field Laboratory, 1800 East Paul Dirac Dr., The Florida State University, Tallahassee, Florida, 32310.

Achromats are the most widely used objectives and are commonly found on both teaching and research-level laboratory microscopes. They are satisfactory objectives for routine laboratory use, but because they are not corrected for all colors, a colorless specimen detail is likely to show, in white light, a pale green color at best focus (secondary axial color). Apochromatic objectives usually contain two lens doublets and a lens triplet for advanced correction of both chromatic and spherical aberrations. With apochromat and fluorite objectives, the diffraction-inducing spreading of the intensity distribution can be virtually eliminated. An achromat objective still has substantial intensity in the first fringe, while the apochromat approaches the theoretical resolution limit where the longitudinal chromatic aberration is greater than the wave-optical depth of field. Because apochromat objectives require lens elements having abnormal dispersion characteristics, their specifications may not be ideal for some specific applications, such as fluorescence excitation in the near ultraviolet, DIC, and other forms of microscopy utilizing polarized light. For this reason, a fluorite objective may be more suitable. Due to modern coating technologies in newly designed apochromats, remarkably sharp images with high contrast can be obtained even in those instances where the apochromat was inherently limited.

Thorlabs expresses LIDT for CW lasers as a linear power density measured in W/cm. In this regime, the LIDT given as a linear power density can be applied to any beam diameter; one does not need to compute an adjusted LIDT to adjust for changes in spot size, as demonstrated by the graph to the right. Average linear power density can be calculated using the equation below.

Below are transmission graphs for the polymer circular polarizers. The polarized input is aligned with the transmission axis of the linear polarizing film. These transmission graphs show only transmission data; output polarization may vary if the input beam wavelength is different from the polarizer's design wavelength.

Types ofmicroscope objectives

These Circular Polarizers are based on a liquid crystal polymer design. They consist of a linear polarizing film and a polymer quarter-wave film, each laminated onto an N-BK7 window. The two laminated substrates are then epoxied together with an optical adhesive, with the quarter-wave film's fast axis oriented at 45° with respect to the polarizing film's transmission axis. A broadband AR coating is deposited on each glass-to-air interface. An arrow marking on the edge indicates the linear polarizing side, as shown in the image to the right.

One of the most important criteria to be considered in the purchase of an optical microscope is the required field of application. Another, perhaps equally important, is the state of (aberration) correction of the optical components, in particular, the objectives. Microscope objectives are perhaps the most important components of an optical microscope because they are responsible for primary image formation and play a central role in determining the quality of images that the microscope is capable of producing. Objectives are also instrumental in determining the magnification of a particular specimen and the resolution under which fine specimen detail can be observed and recorded using the microscope. The objective is the most difficult component of an optical microscope to design and manufacture, and is the first component that light encounters as it proceeds from the specimen to the image plane.

While this rule of thumb provides a general trend, it is not a quantitative analysis of LIDT vs wavelength. In CW applications, for instance, damage scales more strongly with absorption in the coating and substrate, which does not necessarily scale well with wavelength. While the above procedure provides a good rule of thumb for LIDT values, please contact Tech Support if your wavelength is different from the specified LIDT wavelength. If your power density is less than the adjusted LIDT of the optic, then the optic should work for your application.

Please note that we have a buffer built in between the specified damage thresholds online and the tests which we have done, which accommodates variation between batches. Upon request, we can provide individual test information and a testing certificate. The damage analysis will be carried out on a similar optic (customer's optic will not be damaged). Testing may result in additional costs or lead times. Contact Tech Support for more information.

While some of the microscope optical components act as image-forming elements, others serve to produce various modifications to illumination of the specimen and also have filtering or transforming functions. Components involved in formation of images by the microscope optical train are the collector lens (positioned within or near the illuminator), condenser, objective, eyepiece (or ocular), and the refractive elements of the human eye or the camera lens. Although some of these components are not typically thought of as imaging components, their imaging properties are paramount in determining the final quality of the microscope image.

Left-handed circular polarizers will convert a beam with an arbitrary polarization state into a left-handed circularly polarized beam, provided that the input beam is not polarized perpendicular to the linear polarizing film inside. The input surface and transmission axis of the polarizing film is marked by an arrow on the edge of the circular polarizer.

Q10N gimbal and camera features an 10x optical zoom lens. It powered by 1/3 SENSOR CMOS module, supports approx.2.48 million effective pixels, with Color 0.05 ...

Armmicroscope function

LIDT in energy density vs. pulse length and spot size. For short pulses, energy density becomes a constant with spot size. This graph was obtained from [1].

The direction of circular polarization is defined from the point of view of the light source, looking along the optical axis in the direction of propagation. It refers to the rotation of the electric field over time, at a fixed point on the optical axis. "Left-handed" refers to counter-clockwise rotation, while "right-handed" refers to clockwise rotation.

The specifications to the right are measured data for Thorlabs' polymer circular polarizers. Damage threshold specifications are constant for all of the polarizers with the same design wavelength.

Pulsed Nanosecond Laser Example: Scaling for Different Pulse DurationsSuppose that a pulsed Nd:YAG laser system is frequency tripled to produce a 10 Hz output, consisting of 2 ns output pulses at 355 nm, each with 1 J of energy, in a Gaussian beam with a 1.9 cm beam diameter (1/e2). The average energy density of each pulse is found by dividing the pulse energy by the beam area:

Eyepieces work in combination with microscope objectives to further magnify the intermediate image so that specimen details can be observed. Oculars is an alternative name for eyepieces that has been widely used in the literature. The best results in microscopy require that objectives be used in combination with eyepieces that are appropriate to the correction and type of objective. The basic anatomy of a typical modern eyepiece is illustrated in Figure 3. Inscriptions on the side of the eyepiece describe its particular characteristics and function. There are two major types of eyepieces that are grouped according to lens and diaphragm arrangement: the negative eyepieces with an internal diaphragm and positive eyepieces that have a diaphragm below the lenses of the eyepiece. Negative eyepieces have two lenses: the upper lens, which is closest to the observer's eye, is called the eye-lens and the lower lens (beneath the diaphragm) is often termed the field lens. In their simplest form, both lenses are plano-convex, with convex sides facing the specimen. Approximately mid-way between these lenses there is a fixed circular opening or internal diaphragm which, by its size, defines the circular field of view that is observed in looking into the microscope.

Pulsed lasers with high pulse repetition frequencies (PRF) may behave similarly to CW beams. Unfortunately, this is highly dependent on factors such as absorption and thermal diffusivity, so there is no reliable method for determining when a high PRF laser will damage an optic due to thermal effects. For beams with a high PRF both the average and peak powers must be compared to the equivalent CW power. Additionally, for highly transparent materials, there is little to no drop in the LIDT with increasing PRF.

The optical components contained within modern microscopes are mounted on a stable, ergonomically designed base that allows rapid exchange, precision centering, and careful alignment between those assemblies that are optically interdependent. Together, the optical and mechanical components of the microscope, including the mounted specimen on a glass microslide and coverslip, form an optical train with a central axis that traverses the microscope base and stand. The microscope optical train typically consists of an illuminator (including the light source and collector lens), a substage condenser that serves to prepare illumination for imaging, specimen, objective, eyepiece, and detector, which is either some form of camera or the observer's eye.

Ocular lensmicroscope function

The first stage of the microscope optical train (and perhaps the most neglected) is the lamphouse, which contains the lamp and collector lens system. This unit is responsible for establishing the primary illumination conditions for the microscope. Light emitted by a tungsten-halogen or arc-discharge is passed through the collector lens system and the filament or arc is focused onto the front focal plane of the condenser (objective in reflected epi-fluorescence). The first image plane in the microscope optical train occurs at the position of the field diaphragm. Thus, the lamphouse coupled with the field diaphragm produces the necessary illumination pattern to sufficiently image specimens in a wide variety of imaging modes. In the optical microscope, conjugate planes are imaged into each other and can collectively be observed while examining a specimen in the eyepieces. The field iris diaphragm, adjacent to the lamp collector lens, is imaged sharply into the same plane as the specimen by the microscope condenser. Images of both the field diaphragm and the specimen are formed in the intermediate image plane by the objective and are projected into the fixed field diaphragm of the eyepiece, where the focusing reticle is located. Subsequently, the eyepiece (in conjunction with the observer's eye) forms images of all three previous image planes on the sensor surface of an imaging system or the retina of a human eye. The field diaphragm, specimen, intermediate image, and retina all constitute a set of conjugate image planes, spaced throughout the microscope optical train, which appear simultaneously in focus.

The resolution of microscopy methodology refers to its capability to differentiate two closely spaced objects. The resolution of an optical ...

Custom WavelengthThe design wavelength of a circular polarizer is determined by the thickness of a layer of cured, birefringent liquid crystal polymer. This layer is coated on top of the alignment material using a spin coating technique, enabling precise control of the layer’s thickness. Our standard circular polarizers cover many common wavelengths; customized wavelengths between 400 nm and 1600 nm can be specially ordered as well.

Modern microscope objectives belong to a broad family known as infinity color corrected optics that produce a parallel bundle of wavefronts (leaving the rear focal plane), which are then focused onto the intermediate image plane using a tube lens. Because the light rays in these infinity optics are projected in parallel between the objective and the tube lens, filters, prisms, beamsplitters, reflectors, and other plane-parallel components can be inserted into the optical train without the need for additional optical components. Also, infinity corrected objectives are specifically matched in terms of optical factors to a tube lens to produce the final, fully-corrected intermediate image. Classical microscopes with finite optical systems require the eyepiece lenses to perform a portion of the aberration compensation work. The parfocal length of infinity-corrected optical systems (in effect, the distance from the objective mount to the specimen) is in most cases 45 millimeters so that individual objectives are optically and mechanically parfocalized in such a manner that the focal plane is maintained after an objective change without significant re-focusing.

Jan 7, 2024 — I am looking for a file to do the grid pattern on the 30 x 30 MK 2. I will not be using the whole 30 inches since I have the Vortex at the ...

Pulsed Nanosecond Laser Example: Scaling for Different WavelengthsSuppose that a pulsed laser system emits 10 ns pulses at 2.5 Hz, each with 100 mJ of energy at 1064 nm in a 16 mm diameter beam (1/e2) that must be attenuated with a neutral density filter. For a Gaussian output, these specifications result in a maximum energy density of 0.1 J/cm2. The damage threshold of an NDUV10A Ø25 mm, OD 1.0, reflective neutral density filter is 0.05 J/cm2 for 10 ns pulses at 355 nm, while the damage threshold of the similar NE10A absorptive filter is 10 J/cm2 for 10 ns pulses at 532 nm. As described on the previous tab, the LIDT value of an optic scales with the square root of the wavelength in the nanosecond pulse regime:

These polarizers define the direction of circular polarization as viewed from the light source looking along the optical axis in the direction of propagation. "Left-handed" circular polarization refers to the counter-clockwise rotation of the electric field over time, at a fixed point on the optical axis. See the image to the right for a visual representation.

These polarizers are sensitive to stress when mounting. Overtightening the retaining ring can cause stress-induced birefringence in the optic and can reduce the polarization extinction ratio. To secure the polarizer in an SM1 lens tube or SM1-threaded mount, we recommend using an SM1LTRR stress-free retaining ring.

Ms.Cici

Ms.Cici

8618319014500

8618319014500