What's a Parfocal Lens and Why Is It so Important? - parfocal

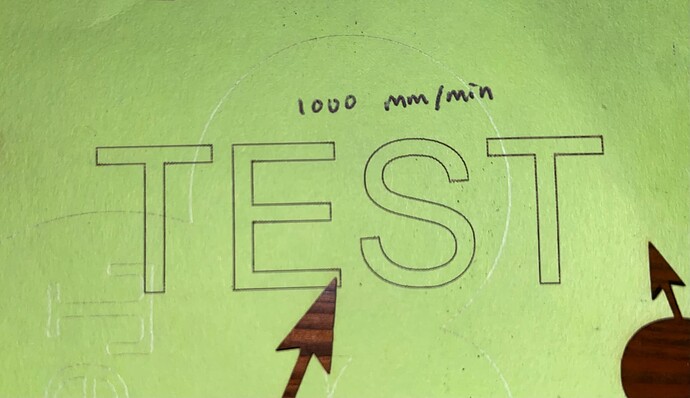

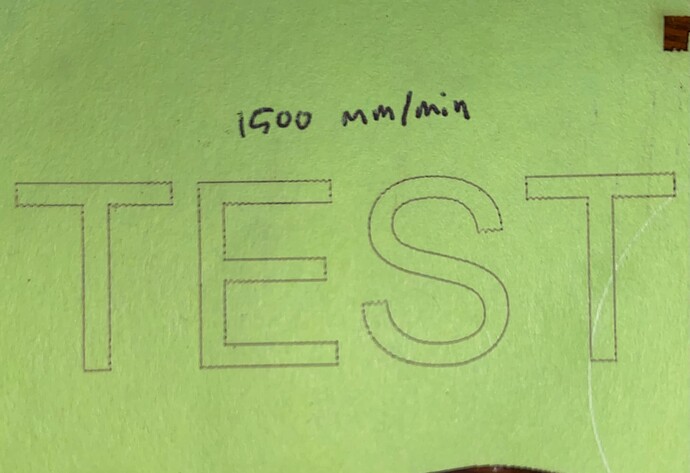

Allen wrenchvs hex key

I am having an issue with my laser burning straight lines. I just had this issue with a previous model and never could get it fixed, even through troubleshooting with an Ortur engineer. Ortur replaced my previous laser with a newer version (I now have the Ortur Laser Master 2 S2) since mine was still under warranty. However, after setting it up, I’m having almost the exact same issue. I have checked a rechecked all belts, bolts, etc. and there is nothing that is loose or that has any kind of play in it. I though maybe somehow it could be a Lightburn issue since when my last laser started this, it was right after an update. I have reinstalled an older version of Lightburn and still am experiencing this issue. I have attached photos with test burns on paper at two different speeds. Any help with this would be greatly appreciated. Thanks.

Allen wrenchsizes

Thanks for the response. I’ve noticed the issue isn’t quite as noticeable at lower speeds, but I had frequently ran projects at 1500 mm/min and up to 2000 mm/min previously with no issue, then this just showed up one day on my old laser. Brand new laser doing the same right out of the box. Just dumbfounded at this point because I’ve tried pretty much everything I can think of or find online.

Allen wrenchhome depot

i don’t know the machine you’re talking about but, laser head carriage is moving on wheels? and there is some eccentric nut? maybe that eccentric is too lose?

The horizontal arm came out of the box already fully installed, but I did check all cables and nuts/bolts to ensure everything was good and tight. Right now, there’s no wiggle or wobble anywhere that I can find.

i had seen these before too when the laser is set up on a non firm table top for example. I have a portable table i use that will get perfect harmonic fibrations at 2500mm/min for some reason

Allen wrenchnear me

Allen wrenchset

@timtacious this might sound like a silly test but a) can you send a image of how your module is set up - to focus. Assumning you testing on paper and assuming you have a LU2-4-SF its fully extended down? b) can you try the same test wheere machine is set on the floor?

I can get some pictures when I get it set back up to try and troubleshoot later, but the laser is on a large, 2x2 piece of plywood with 3D printed braces around the feet to prevent it from moving. And yes, I ran these tests on paper using the acrylic focusing tool to get the right laser height. I haven’t tried running the new laser on the floor, but the previous one that I had this issue with I actually did think to try running it on the floor just to see if it was an issue with my worktable. I came up with the same results.

Hello timtacious Even if the machine appears to be on solid ground (it has rubber bumpers), vibration can cause these jagged lines. This is also the case with milling machines. In machines with axles running on wheels, the slightest deviation in concentricity can lead to such errors. This would mean that the error could be reduced at a different speed or acceleration. Only trying helps. Another cause could be - but this is only a theory - that the workpiece to be lasered moves slightly due to the finest vibration. A connection with the LightBurn software seems very unlikely to me; an output of the GCode in a file would show that.

Ms.Cici

Ms.Cici

8618319014500

8618319014500