What is the Role of Lenses in Microscopy? - define objective lens microscope

Presented in Figure 1 is a cut-away diagram of a typical helium-neon laser system, which is constructed of glass with a large oxidized-aluminum cold cathode as the electron emitter. Operating in the abnormal glow current density gas discharge region, helium-neon lasers are generally high-voltage and low current systems, with discharge currents being limited to a few milliamperes and potentials ranging from several hundred to a thousand volts. Progressive deterioration of the oxide coating on the cathode, which ultimately leads to sputtering of aluminum, is the limiting factor in helium-neon laser operating life. Large-diameter discharge tubes typically have longer life spans than smaller tubes (40,000 hours versus about 10,000 hours, respectively).

NIR imaging technology marks a significant advancement in the field of optical imaging. It utilizes the electromagnetic spectrum, specifically wavelengths beyond the visible light spectrum, ranging from 650nm to 950nm. Capable of penetrating complex objects, it provides detailed images under various conditions.

Laser

NIR cameras typically use color filters to improve the quality of the captured images. For example, RGB color filters can be used to simplify palette selection and improve color accuracy. However, in NIR imaging, these filters can be adjusted or replaced with infrared-pass filters to allow more near-infrared light to reach the sensor, resulting in clearer images.

To achieve NIR imaging, cameras are typically equipped with a thicker base layer, which is more sensitive to the near-infrared spectrum than the visible spectrum. This allows for the capture of high-quality images even in extremely low ambient light. The process involves the following steps:

Rubylaser

Sinoseen boasts over 14 years of experience and expertise in the field of embedded vision, with a professional team that has provided dedicated NIR camera support for more than 50+ clients. Should you require the integration of a suitable camera for NIR imaging, feel free to contact us, and we will offer you the most professional one-stop customized service.

In the industrial sector, NIR cameras are used for quality control, inspecting products for defects or foreign objects, and monitoring manufacturing processes. They can also be employed in agriculture to assess the health of crops and predict yields.

NIR imaging is a cutting-edge technology offering unique perspectives in the wavelength range of 650nm to 950nm. Unlike visible light imaging, NIR is less affected by color changes, enabling high-precision visualization of any object. This distinctive feature makes NIR imaging a forefront technology in numerous fields, from medical diagnostics to industrial quality control.

According to recent market research, the NIR imaging market is on an upward trend. The market size has doubled from approximately $285 million in 2019 and is projected to reach $485 million by 2030. This growth can be attributed to the increasing adoption of NIR technology in healthcare, security, agriculture, and industrial inspection.

Solid-statelaser

NIR cameras are designed to detect and process light within the near-infrared range, typically between 700nm and 1000nm. This is achieved through specialized sensors that are more sensitive to infrared light than visible light. The high quantum efficiency (QE) of these sensors ensures that a majority of incident photons are converted into electrons, which are then processed into usable images. Quantum efficiency is a key parameter for NIR camera performance. It measures the camera's ability to convert incident photons into detectable electrical signals. A higher QE means better image quality, even under low-light conditions.

Helium-neon lasers are among the most widely utilized laser systems for a broad range of biomedical and industrial applications, and display a superior Gaussian beam quality that is virtually unrivaled by any laser. These lasers are readily available at relatively low cost, have compact size dimensions, and exhibit a long operating life (often reaching 40,000 to 50,000 hours). The low power requirements, superior beam quality (virtually a pure Gaussian profile), and simple cooling requirements (convection) make helium-neon lasers the choice system for many confocal microscopes.

In the R&D sector, NIR cameras are invaluable for analyzing materials with unique NIR spectral characteristics. They assist scientists and researchers in identifying and quantifying specific substances, which is crucial for drug development, chemical analysis, and materials science.

Semiconductorlaser

Proper exposure control is crucial for capturing high-quality NIR images. Overexposure can cause image washing out, while underexposure can lead to noisy or dark images. NIR cameras usually have automatic exposure features that adjust exposure time and aperture to achieve the best image under varying lighting conditions. Additionally, maintaining the correct aspect ratio ensures image distortion is minimized, which is vital for accurate analysis and interpretation.

NIR imaging employs continuous wave motion principles, offering a unique sensitivity curve that clearly projects distant objects. Compared to traditional imaging methods, NIR imaging is not color-dependent, meaning it can provide high-contrast images, making them easier for human observers to interpret.

2nd Floor,Building C,Innovation Silicon Valley Industrial Park,No.17,Jingtian Road,Guanhu Street, Longhua New District,Shenzhen,Guangdong,China

The realization of NIR imaging demonstrates the progress in sensor technology and understanding of the electromagnetic spectrum. NIR imaging is achieved through specialized cameras sensitive to the near-infrared range near the visible spectrum. It covers wavelengths just beyond the range of visible red light, which is approximately 700nm, up to 950nm.

CO2laser

One of the main advantages of NIR imaging is its ability to penetrate certain materials, such as plastics and human tissue. Additionally, NIR imaging systems can operate effectively under low-light conditions, with good sensitivity and high-resolution capabilities.

Nitrogenlaser

Once NIR light is captured by the camera's sensor, it undergoes a series of image processing steps. These steps may include noise reduction, contrast enhancement, and color correction. Advanced image processing algorithms can also be used to extract specific information or enhance the visibility of certain features in the image.

Dyelaser

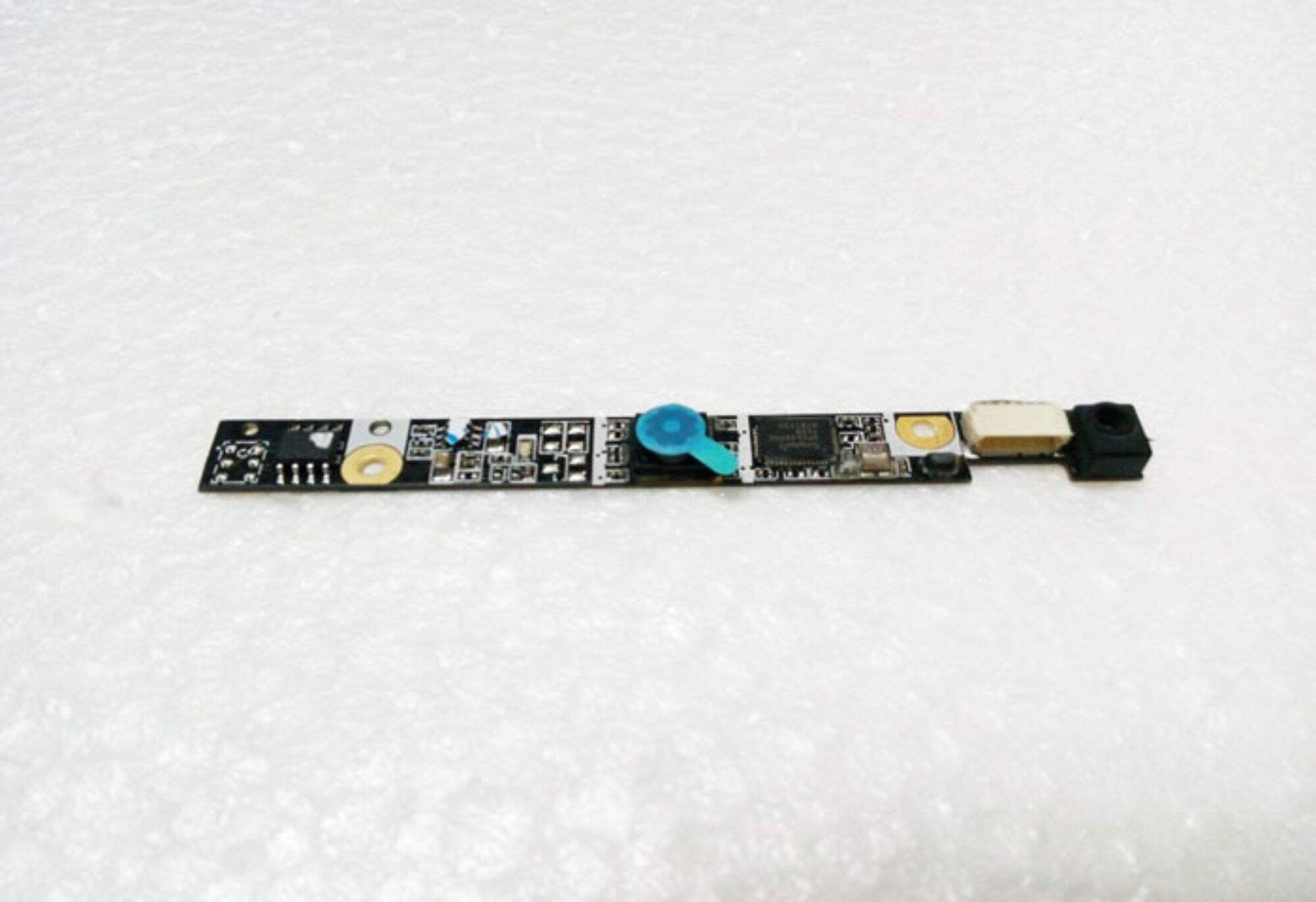

China top 10 camera module manufacturer. We customize all kinds of USB/MIPI/DVP camera modules as per your request. We are confident to offer customers with the most competitive price and quality. Any product related with camera module,we can find the best solution.

The tutorial initializes with a cutaway drawing of a helium-neon gas laser illustrated in the central window, and having the operating speed set to Medium, a level that enables the visitor to observe the slow build-up of light in the laser cavity as it is reflected back and forth through the Brewster windows and mirrors. In order to operate the tutorial, translate the Laser Wavelength slider between the various available laser spectral lines (543, 594, 612, 633, and 1523 nanometers), and observe how the color of the output beam changes with wavelength. Use the Tutorial Speed slider to adjust the speed of light oscillations within the laser cavity and the level of light emitted through the output lens.

However, NIR imaging also faces some challenges. For instance, objects with wavelengths beyond 700nm to 1000nm may not be visible to NIR camera module. Moreover, due to the lack of ambient light, NIR imaging may require additional light sources in nocturnal scenarios.

OEM IMX258 13MP mipi Camera Module 4K Camera Module Autofocus Camera Module wide-angle mini for Machine Vision Product Vision

NIR technology plays a significant role in biometric systems, particularly iris recognition. The technology can capture detailed images under various lighting conditions, making it an ideal choice for secure access control applications.

Capturing images in RAW format provides greater flexibility in post-processing as it preserves more of the original image data. This is particularly useful in NIR imaging, where analysis often requires the highest possible image quality. Using high-quality IR filters can also enhance image clarity by blocking unwanted light wavelengths.

NIR cameras, such as those used for night vision or traffic monitoring, are designed with sensors highly sensitive to the near-infrared spectrum. Traditionally, CCD sensors were used for NIR imaging, but the emergence of CMOS technology has revolutionized the field. CMOS sensors exhibit greater sensitivity in the near-infrared range, especially above 850nm, making them more cost-effective and suitable for a broader range of applications.

Ti:sapphirelaser

In the past, the application of helium-neon lasers in confocal microscopy was somewhat hampered by the relatively low intensity and red emission wavelength. This difficulty has been overcome in part by the development of new lasers having additional spectral lines. The emission at 633 nanometers (termed the He-Ne line) of the common helium-neon laser has been supplemented by development of variants having emissions in the green (543 nanometers), yellow (594 nanometers), orange (612 nanometers), and near infrared (1523 nanometers) spectral regions. Typical power output values for the 633 nanometer red spectral line range from 0.5 to 10 milliwatts up to a maximum of about 75 milliwatts. The introduction of semiconductor and diode lasers having spectral lines in similar wavelength regions may ultimately lead to a reduction in the use of helium-neon lasers for confocal microscopy.

Moreover, the quality of NIR imaging can be significantly enhanced using specific techniques and tricks. For instance, image intensifiers can boost the camera's ability to capture usable images under low-light conditions. Additionally, the use of filters can help block unwanted wavelengths, ensuring that the camera only detects near-infrared light relevant to the current application.

Ms.Cici

Ms.Cici

8618319014500

8618319014500