What is Polarization of Light: Definition, Types and Examples - polarization of light examples

Note that this curve is different for every wavelength and f/# (or NA). However, the only thing that changes is the scale of the abcissa (x-axis). The cutoff frequency is given by

Using C-mount lenses has many benefits, they are designed specifically for use in industrial environments. They are built to be robust and durable to withstand harsh conditions such as high temperatures, humidity, vibration, and other adverse factors. Some other advantages include:

One final pointer: We are often asked, “What MTF is good enough?” The answer is, of course, “it depends…” But a good rule of thumb is that when the MTF drops below 0.2 (20%), it is probably unacceptable. Beyond that, lenses are rarely as good as the ideal model in the computer. How much difference depends on the manufacturer and the tightness of tolerances. Tolerances are discussed on another page.

So how does that relate to spatial frequency? Actually, dpi is spacial frequency! Let’s change the units to make this clear. To make one cycle, we need two pixels so one can be on and the other off. This means that 400 dpi = 200 cycles per inch. Since optics is done in metric, we still need to convert to millimeters. There are roughly 25 mm in 1 inch, so we just divide cycles per inch by 25. Thus 400 dpi = 200 cy/in = 8 cy/mm.

From this equation, you can see that if min = 0, modulation will be 1.0, and if max = min, the contrast will be 0.0. When the modulation is near one, the contrast is very high, and the image looks sharp. Conversely, when the modulation is near zero, it is so blurred that it is difficult or impossible to see details.

Spatial Frequency is defined as one divided by the period of a repeated structure. A picture would probably be helpful here.

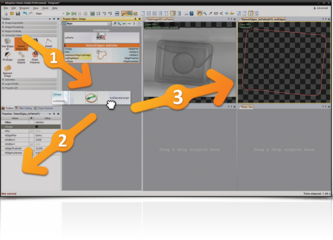

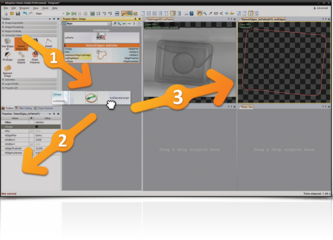

Framoslens

If you in the process of selecting the right lens for your machine vision application, it is essential to consider various factors. These factors include the desired field of view, working distance, sensor size, and required focal length. To help you calculate the right lens, you can use our Lens calculator to determine the right focal length for your application. This tool can also be used as a C-mount lens calculator for your specific field of view. Another point to consider is the match between the lens resolution (resolving power) with the pixel size of your industrial camera. You can read more about this on this article: "How to select the best lens resolution for the pixel size of your camera". This article explains in detail the relationship between the lens resolution and pixel size. We have an experienced team that can help you select the best lens for your application. Please contact us for a direct assistance!

Another way to get a picture of spatial frequency is to think in terms of dots per inch (dpi). Computers went through a revolution when Hewlett Packard introduced its first laser printer that produced 300 dpi. A few years later 600 dpi became the norm and now printers put out so many dpi that we don’t care anymore. The same thing is happening in cell phones. My first cell phone had a 1.75″ display with 320 x 240 resolution. That works out to 230 dpi. Now you can get a cell phone with over 400 dpi, so the picture is much sharper.

MTF stands for Modulation Transfer Function. It is a function that calculates the sharpness or fuzziness of an image. It is important to understand several terms before we can fully describe MTF.

Cs mount

Modulation: Assume the above square wave plot is the amount of light in an image, and the peaks represent bright portions and the valleys represent dark portions. Let’s call the amount of light in the peaks “max” and the amount in the valleys “min”. Then the modulation, or contrast, is given by:

Tangential: related to resolution for periodic patterns with the period tangent to a circle centered on the optical axis.

C-Mount

Based on these definitions, we can state that MTF is a plot of contrast versus spatial frequency. Experience tells us that smaller details are harder to see. In terms of MTF, this is expressed by saying that the modulation decreases as spatial frequency increases. Somewhat surprisingly, this is true even for lenses that are perfect. Such lenses are called “diffraction limited” because a physical phenomenon called diffraction keeps them from resolving infinitesimal detail. A plot of MTF for a perfect lens is shown below.

Saggital: related to resolution for periodic patterns with the period parallel to a line through the center of the image.

C mount1 32 un 2b

Note that there are now five curves on the plot rather than just one and also that the maximum spatial frequency is only 100 cy/mm rather than 840. The blue curve (labeled TS 0.00 deg) is for the center of the image. Before discussing the green and red curves, we need two more definitions.

Some types of lenses, such as telescopes and microscopes, commonly reach the diffraction limit. Others, for example camera lenses, rarely approach the diffraction limit. A camera lens might have an MTF plot like the one below:

In the square wave pictured above, the spatial frequency would be 1.0 divided by the distance shown. For example, if one period is 10mm, the spatial frequency would be 0.1 cycles/mm, sometimes written 0.1cy/mm. It is important to remember that spatial frequency increases as the period gets smaller.

As you may have surmised by now, periodic patterns away from the center of the image have an MTF that depends on their orientation. If you orient a periodic pattern of parallel lines so one of the lines passes through the center of the image, the MTF of that pattern will be determined by the Saggital MTF curve, which is the one labeled S. MTF also varies with the distance from the axis of symmetry (optical axis) of the system. That’s why there are separate curves for 0.00 deg (the optical axis or center of the image), 14 deg and 20 deg. This particular lens was analyzed by tracing rays through the lens that made a 14 degree angle with the optical axis and another set at 20 degrees. In this lens, things don’t get much worse between 14 and 20 degrees, but they are different. Other lenses will behave differently, depending on the aberrations of the optical system. But that’s another topic.

What should I consider when looking for a C-mount lens? For every lens series, a variety of focal lengths are available. Most of our C-mount lenses have a fixed focal length, providing stability in your application and enabling high resolution and contrast in captured images. This makes them ideal for use in industrial applications, where fixed parameters such as working distance and field of view are necessary. The cost of a fixed-focus lens is relatively low, allowing the possibility of meeting the needs of large-scale industrial productions. If you in the process of selecting the right lens for your machine vision application, it is essential to consider various factors. These factors include the desired field of view, working distance, sensor size, and required focal length. To help you calculate the right lens, you can use our Lens calculator to determine the right focal length for your application. This tool can also be used as a C-mount lens calculator for your specific field of view. Another point to consider is the match between the lens resolution (resolving power) with the pixel size of your industrial camera. You can read more about this on this article: "How to select the best lens resolution for the pixel size of your camera". This article explains in detail the relationship between the lens resolution and pixel size. We have an experienced team that can help you select the best lens for your application. Please contact us for a direct assistance! Advantages of C-mount lenses Using C-mount lenses has many benefits, they are designed specifically for use in industrial environments. They are built to be robust and durable to withstand harsh conditions such as high temperatures, humidity, vibration, and other adverse factors. Some other advantages include: Suitable for image sensors up to 1.4; Manual aperture (iris) adjustment; Manual focus setting; Screws to fix securely the iris and focus position; You can easily and securely mount the lens; Selected lenses with very high light sensitivity, apertures ranging up to F1.4 Applications for C-mount lenses C-mount lenses are versatile optical tools employed in a wide spectrum of applications, including quality control, inspection, and monitoring of the production process in machine vision systems. In robotics and automation, they serve as essential components for object identification, positioning, and tracking. Their ability to provide sharp and detailed images is particularly valuable in scientific research and medical imaging for capturing intricate details of samples and tissues. From inspecting products on assembly lines to assisting robots in manipulating objects, C-mount lenses demonstrate their adaptability and versatility across diverse fields. Get Cameras portfolio of C-mount lenses We have more than 50 different C-mount lenses on offer in our portfolio, GeT Cameras provides an extensive line of high-performance lenses for each resolution level (45MP, 25MP, 20MP, 10MP, 12MP or 5MP), each with different focal lengths and sensor sizes. We also offer options of macro lenses and varifocal lenses. If you could not find a solution for you in our online store//if your applications requires a very specific solution that you cannot find directly in our portfolio, please make an enquiry for custom C-mount lenses. Our goal is to provide high-quality products with an extremely low level of variation among individual lenses. Are you in need of a perfect camera to match with your C-Mount Lens? Check out our selection of Machine Vision Cameras. Differences of C-mount lenses Our portfolio of standard C-mount lenses can be divided into three categories based on their focal length, aperture, and optical design: Fixed focal length lenses: This type of lens is the standard in machine vision applications. While focus and aperture can be set, the focal length (magnification) can’t be changed. This enables the manufacturer to construct a lens with more light sensitivity, compared to other types of lenses. In addition, less mechanical parts make the lenses more rigid and reliable to perform in an industrial environment. The focal length of a lens depends on the sensor size, working distance and desired field of view for the application. Our lens calculator is a perfect tool to determine the needed focal length. Zoom lenses: These lenses offer a variable magnification, allowing for a wide range of field of views without changing camera position or more flexibility in the working distance. They are typically characterized by their maximum and minimum focal length. Zoom lenses are available in manual focus or motorized/autofocus such as those commonly used in CCTV systems and machine vision applications. Macro lenses: These lenses are specialized for close-up images, designed for high resolution applications where a short working distance is required. They feature a short minimum focusing distance and a shallow depth of field, making them ideal for capturing intricate details of small subjects. We have macro lenses available for 12MP resolution for 25, 35, 50 and 75mm focal length. In addition, we have also available telecentric C-mount lens that you can use in your application. Lens filters and adapters for a C-mount lens We offer a wide portfolio of lens filter for C-mount lenses. With our filters you can improve the contrast in your machine vision application. You can find a diverse range of bandpass, long pass, UV, NIR and polarizing filters. Choose from a variety of filter threads to match your specific C-mount lens. If you are using a camera with a CS-mount, you can simply pair your C-mount lens with our C-EXTENSION-RING-5MM adapter and easily integrate it into your system. It is also possible to use a focal extender such as our 2x focal length extender or our 4x focal length extender. to zoom a factor of 2 or 4 and increase your focal length of a C-mount lens. These focal extenders can be very useful when working with a C-mount lenses with a microscopic for example, where the field of view is usually smaller. C-mount lenses production and quality control Our manufacturing facility has the capacity to produce more than 300,000 lenses each year. We keep a stock of 500 units specifically for machine vision lenses. These lenses undergo meticulous crafting and polishing to attain the precise aspherical size. Constructed with glass elements and housed in metal, the initial production step involves cutting the glass elements, followed by polishing and thorough cleaning. Rigorous quality control measures are implemented to ensure that our C-mount lenses meet stringent quality standards, providing an outstanding price-performance ratio. C-mount lens shock & vibration test The industrial c-mount lens for Machine Vision applications is tested on shock and vibrations. The lens is designed with glasses that are fixed with a pressure ring. Lenses are tested under the following conditions: Vibration testing: a generated sine wave with an amplitude of 1.5mm and a frequency of 10hz-55hz will shake the lens for 25 minutes in three perpendicular directions Drop test: The lens, packaged in the standard package, is dropped 5 times, each from 1 corner, 3 edges and 6 sides at a height of 1m on a rigid surface (steel plate) For machine vision applications where the c-mount lens might vibrate, we advise to use blue Loctite® glue to be sure that the lens locking screws for focus and aperture will not vibrate or loosen up. These are best practices for industrial C-mount lenses.

Ms.Cici

Ms.Cici

8618319014500

8618319014500