UV Curing Systems - uv light curing systems

When reading the scale, be sure to read the scale from the front. As shown in the figure, changing the eye position from (A) to (B) to (C) will change the scale alignment position. To avoid errors due to eye position, read the scale from the position (B) perpendicular to the point where the sleeve reference line and thimble scale line meet.

Solutions promoting color or signal separation, signal and “color” isolation, color temperature correction, aesthetic lighting effects, selective wavelength or color illumination, Dichroic color separation, filters for Heads Up Display (HUD).

A micrometer is a simple-looking tool, but the standard model can read down to 1 μm(micrometer). 1 μm is 1/1000 of 1 mm, which is about 90 μm for copy paper, 70 to 80 μmfor a hair, and 10 μm for food film. This unit is very fine, showcasing how precise a tool such as the micrometer is.

Here we explain the main usage and precautions, using a standard outside micrometer as an example. Micrometers can measure from 0 mm to 2000 mm. Confirm the measuring range and select a type suitable for the shape of the object to be measured and the purpose of use.

The thimble scale is read where the reference line on the sleeve and the thimble scale line are aligned. If there is a deviation, read the scale below the reference line. The sleeve scale reads the maximum visible value.

Opticalcoating jobs

Abbe's principle states that "the object to be measured and the standard scale must be aligned in the direction of measurement". Micrometers are tools based on this principle and are capable of higher precision measurements than calipers and other measuring instruments.

Cold & Hot Mirrors assist with redirecting infrared (heat) & light where best utilized or removed. ITO coated Total Solutions are electrically activated so as to heat surfaces for anti-fogging, de-icing & maintaining temperature while imaging.

Abrisa Technologies works in close collaboration with you, our customer to understand your market challenges and your program needs. Our expertise in photonics enabled applications and design capability in thin film optical coatings and technology glass combined with our volume manufacturing experience, makes us uniquely positioned to offer technical solutions and economies of scale not available from other glass or optical coating sources. Our team provides Total Solutions with single-point accountability that embody application specific optical performance, fitness-for-use enhancements and excellent economies of scale with volume manufacturability to meet your program and budget needs. Abrisa Technologies, your Total Solution Partner from concept to production.

Anti reflective coating

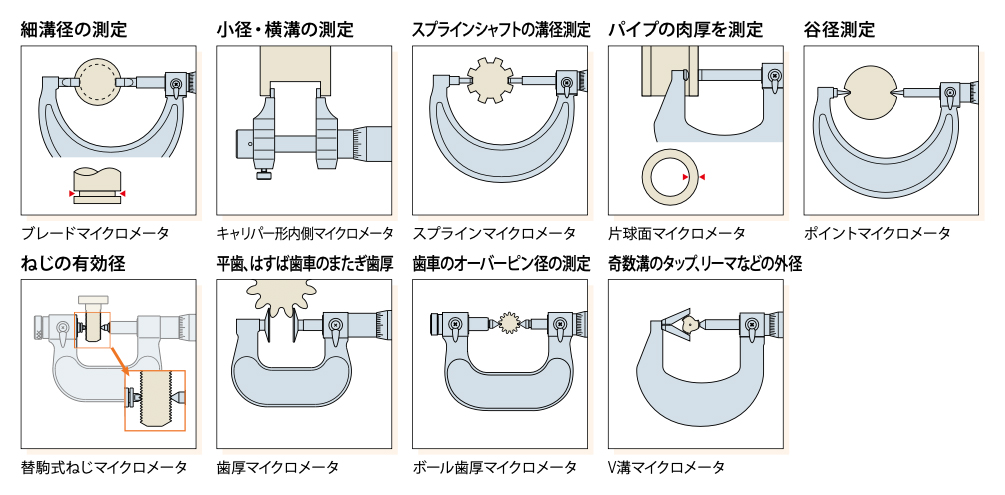

Generally speaking, micrometers are cylindrical in shape, with the measuring surfaces facing each other, but there are various types of micrometers for different purposes.

When the ratchet stop is turned, it spins with a crackling sound to apply the appropriate measuring force to the surface to be measured.

ZC&R Coatings for Optics (ZC&R), an Abrisa Technologies company, designs and manufactures innovative precision thin film optical coating solutions for Micro-electronics, Defense and Avionics, Display, Industrial Automation, Optical Sensors and Imaging, Photonics, Medical/Dental, Life Science Analytics, and other market applications. Custom designed and standard optical coatings are available for use from 200nm in the UV up to 20 microns in the far infrared, with thicknesses of a few angstroms to 10’s of microns. We use advanced Physical Vapor Deposition (PVD) processes including sputtering and Ion Assisted Deposition (IAD) e-beam to deposit optical coatings on a variety of materials including fabricated and polished glass, HIE™ aluminosilicates, wafers, ceramics, crystalline quartz, filter glass, IR materials, polished metals, and other materials of our and customer furnished supply. Contact us with your request.

Coated solutions designed to manage UV & IR content along with visible light spectrum from broadband lighting, solar sources & lasers. Solutions to enhance or block throughput, filter for select UV, provide solar suppression & manage heat and IR.

Optical coatingsapplications

Reflective & partially reflective coatings for laser beam steering, imaging, scanning, LiDAR, visible signal suppression, heat management of illumination sources. Metallic, dielectric & hybrid cut-to-order & custom from mm to meter sizes.

Unique optical coatings designed to meet rigorous optical specifications as well as thermal, mechanical, weathering or bio compatibility requirements for challenging use environments as medical, dental, military, outdoor, UV/IR & high heat.

As shown in the figure below, there are various other types available for different purposes of use, such as measuring the diameter of narrow grooves, pipe wall thickness, and gear overpindiameter. *We can also accommodate custom-made products according to the purpose of use.

Types of lens coating for glasses

Since ancient times, measurement has been necessary in various aspects of human society, including pyramids. In manufacturing, "what cannot be measured correctly cannot be processed correctly," and "measurement" is essential to evaluate the quality of products. A micrometer is one of the indispensable tools for precision measurement.

Micrometers are indispensable precision measuring tools in the manufacturing field. This section provides basic explanations of the measurement methods and features of micrometers, as well as correct usage and precautions.

Types ofoptical coatings

AR coatings are all dielectric single or multi-layers, designed to minimize losses & reduce ghost imaging caused by surface reflections in the UV, visible, near & far IR. They can be designed for laser lines or broadband use & range of angles.

Opticalcoating companies

Beam Splitters separate incoming light into two beams. In reverse, they combine. Partial transmitters allow a portion of incoming light to pass & reject the rest. Can be metallic, dielectric or a mix & rejected light absorbed, reflected or both.

Examples of typical types include the "caliper type inside micrometer" for measuring small diameter and horizontal grooves, the "replacement piece type screw micrometer" for measuring the effectiveness of screws, and the "tooth thickness micrometer" for measuring the straddle tooth thickness of spur and helical gears.

Custom Indium Tin Oxide & Index-Matched Indium Tin Oxide (ITO/IMITO) coatings for photonics. Optimized for durability & index matched for transmittance in excess of 98%. Optional glare reducing broadband & laser line anti-reflective properties.

As part of daily maintenance, thoroughly wipe away dust and chips from the outer circumference of the spindle and the measurement surface. Also, thoroughly wipe away dirt and fingerprints from each part with a dry cloth.

Opticalcoating process

When measuring, slowly bring both measuring surfaces into light contact with the workpiece to be measured in the same posture and under the same conditions as when the base point was checked, and turn the ratchet stop slowly 3 to 5 times to avoid excessive measuring force by the spindle. To avoid deformation of the workpiece, turn the ratchet stop slowly during contact.

Ratchet stop type is generally used as a device to keep the measuring force constant, but friction thimble type and ratchet thimble type are also available for the same purpose.

Cold mirrors reflect UV or the visible & transmit the infrared (heat) at temperatures to ≥400°C. Hot mirrors or shortwave pass filters (SWP) reflect the infrared & separate it from an application. ITO heated windows heat to an ambient temperature.

A micrometer is a tool to precisely measure the outer diameter and length (thickness) of an object to be measured by clamping it. The measurement method uses a precision screw with a pitch of 0.5 mm, and the rotation of the screw is calculated as the axial displacement of the screw. Currently, there are models that use a 2.0 mm pitch precision screw, enabling faster measurement by using a screw with a larger pitch.

Optical coatingsfor lenses

For example, more than 3,000 micrometers are actually used at production sites of aircraft-related companies, playing an important role in air safety. *The above is a description of the outer micrometers.

Coatings as Indium Tin Oxide (ITO) are used to shield electromagnetic interference (EMI) while transmitting high levels of visible light or displayed image, to heat windows for anti-fogging & serve as transparent electrodes for LC based devices.

When mounting the micrometer on a micrometer stand, clamp it across the center of the micrometer frame and do not excessively tighten. Then, adjust the angle of the stand so that the upper and lower scales are evenly visible centered on the zero scale line of the thimble, and fix it in place.

Ms.Cici

Ms.Cici

8618319014500

8618319014500