USB Cameras | Shop USB 2.0 and USB 3.0 Digital Cameras - digital camera with usb cable

Analyzing the interference of light passing through two slits lays out the theoretical framework of interference and gives us a historical insight into Thomas Youngâs experiments. However, most modern-day applications of slit interference use not just two slits but many, approaching infinity for practical purposes. The key optical element is called a diffraction grating, an important tool in optical analysis.

Ozone is a gaseous form of oxygen which is formed by ultraviolet light generated from arc type UV lamps (not LED lamps which generate no ozone). It’s characteristic odor is readily detectable at low concentrations (0.02 to .05 parts per million). Excessive exposure to ozone produces local irritation of the eyes and of the respiratory tract. It can be dangerous at higher than acceptable levels in the workplace. Be sure your equipment has adequate ventilation. Do not use your equipment in a confined space. Maintain work area ozone levels below the OSHA permissible exposure limits of 0.1 part of ozone per million (ppm) of air in an 8-hour time weighted average. Maintain a healthy work area by monitoring ozone levels using detecting instruments such as the EZ-1X device available from Ozone Solutions.

Take the same simulation we used for double-slit diffraction and try increasing the number of slits from N=2N=2 to N=3,4,5...N=3,4,5.... The primary peaks become sharper, and the secondary peaks become less and less pronounced. By the time you reach the maximum number of N=20N=20, the system is behaving much like a diffraction grating.

Cross Scratch Test: A cross scratch test is simple, and only requires a blade. You will know an image will not stand the test of time if a blade is pressed against it and scratches it off. You might even be able to remove the ink using your fingernail.

24.7M posts. Discover videos related to Focal Length Comparison on TikTok. See more videos about Medium Length Haircut.

Diffraction gratings work both for transmission of light, as in Figure 4.14, and for reflection of light, as on butterfly wings and the Australian opal in Figure 4.15. Natural diffraction gratings also occur in the feathers of certain birds such as the hummingbird. Tiny, finger-like structures in regular patterns act as reflection gratings, producing constructive interference that gives the feathers colors not solely due to their pigmentation. This is called iridescence.

Great customer service is part of our culture here at Systematic Automation. We’re ready and happy to help you with your questions, and assist you in selecting the right machine for your specific application. We’re also happy to provide you with a customized quote. Just get in touch - we’d love to hear from you.

RFLXF | Complete Reflex Advanced Materials Corp. stock news by MarketWatch. View real-time stock prices and stock quotes for a full financial overview.

Diffraction grating imagesfree

"We were new to screen printing and Systematic Automation helped us from the beginning of what inks to choose, making our screens and training us on screen printing. We still call for assistance now and then and are met with immediate support."

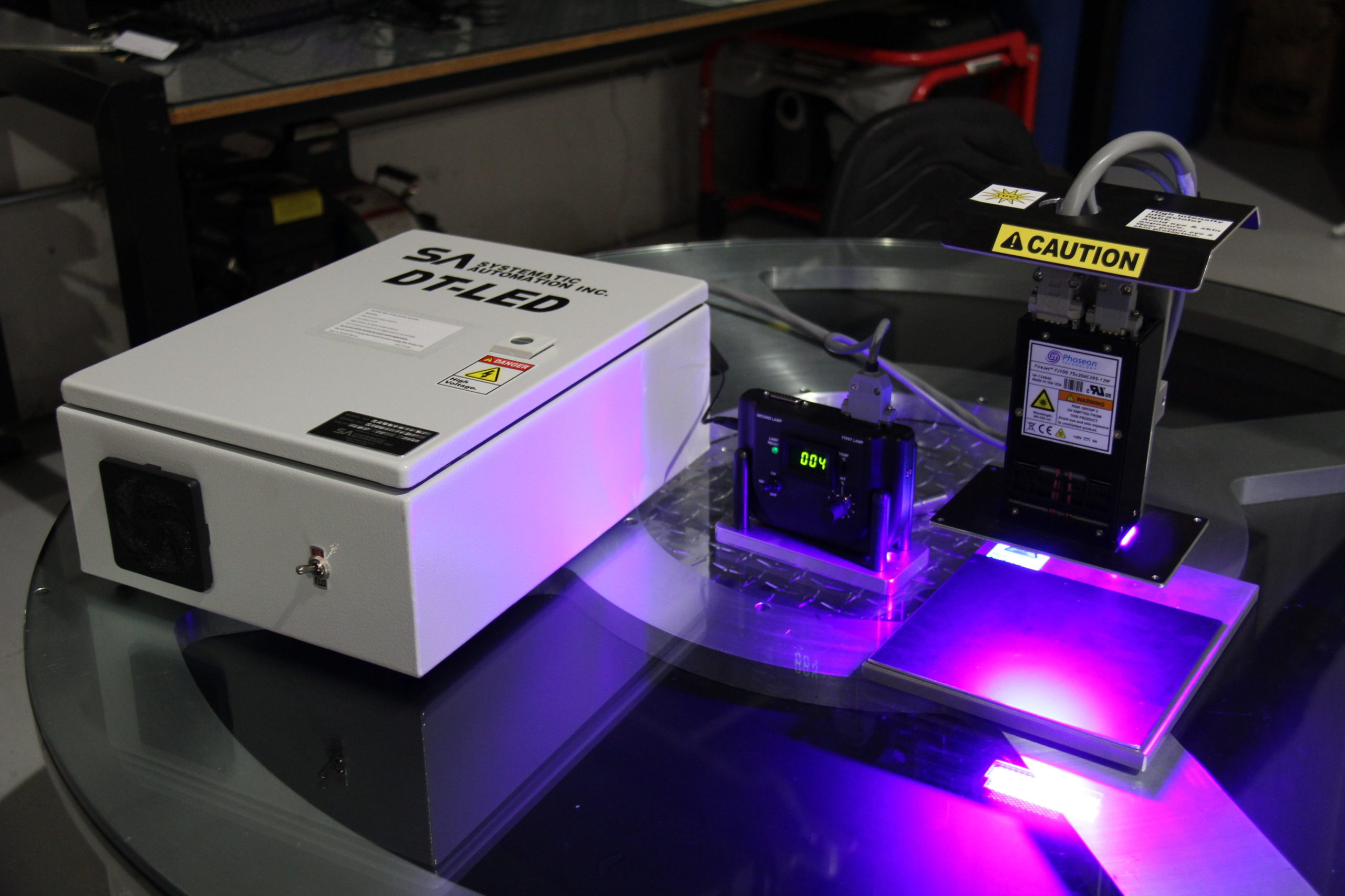

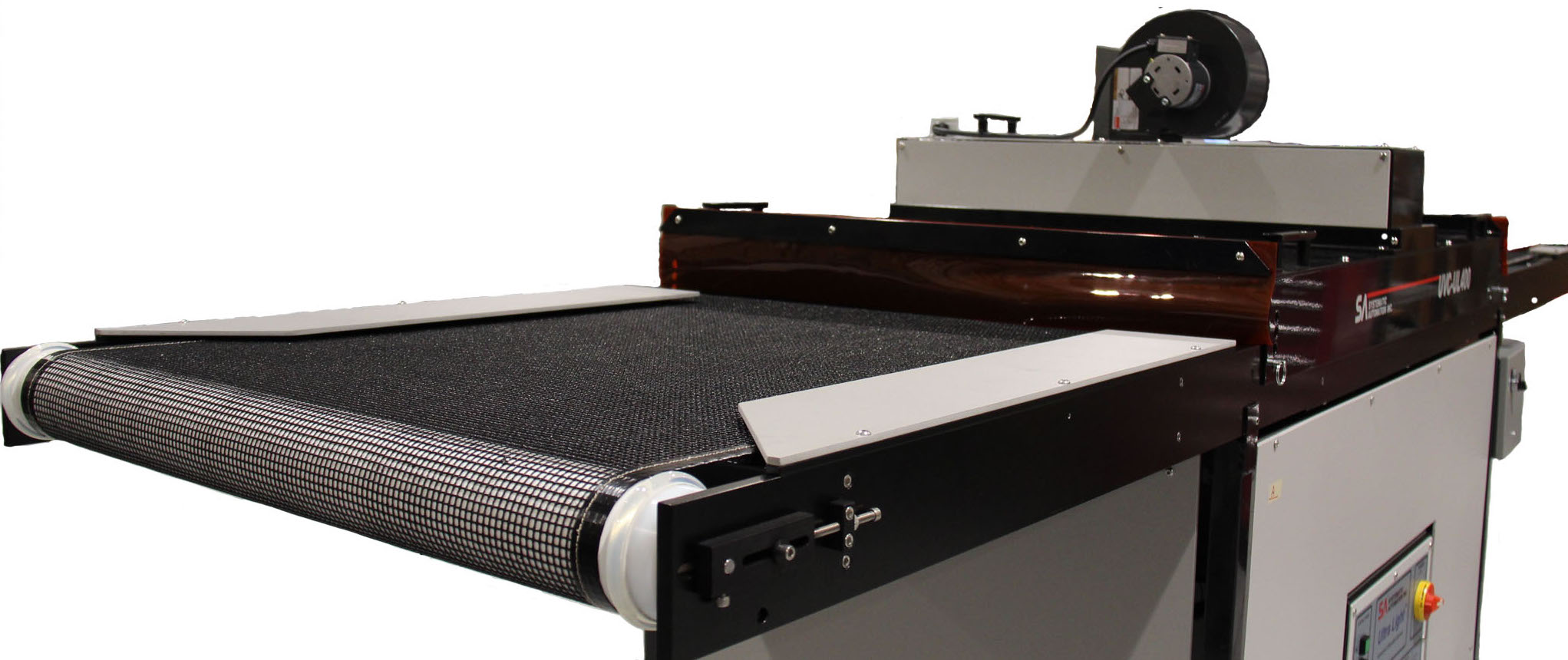

In recent decades, UV curing technology has grown rapidly. The instant curing technology that revolutionized printing has now spread to other industries and technologies due to its ability to be processed and packaged within seconds of exposure.

An iron lamp will significantly increase intensity. Nanometer ranges are available on our website under UV and lamps. Iron spikes in the 395 nm range. Gallium additive is also available with a peak in the 410 nm range. Your ink supplier will verify if this will be more effective. If so, we recommend you try out an iron lamp and raise the lamp an inch or more. By raising it, you will allow more of the light emanating from the center of the lamp to reach to outside of the material being printed. Iron lamps and additive lamps in our experience are harder to start (they may need to be fully cool to start and may require more than one attempt). They also have a shorter life.

Systematic Automation offers UV curing solutions for your application and budget. Contact us to learn more about the best options for your business.

In reality, the number of slits is not infinite, but it can be very largeâlarge enough to produce the equivalent effect. A prime example is an optical element called a diffraction grating. A diffraction grating can be manufactured by carving glass with a sharp tool in a large number of precisely positioned parallel lines, with untouched regions acting like slits (Figure 4.13). This type of grating can be photographically mass produced rather cheaply. Because there can be over 1000 lines per millimeter across the grating, when a section as small as a few millimeters is illuminated by an incoming ray, the number of illuminated slits is effectively infinite, providing for very sharp principal maxima.

Since there are 10,000 lines per centimeter, each line is separated by 1/10,000 of a centimeter. Once we know the angles, we an find the distances along the screen by using simple trigonometry.

A high quality cable, rated at 20 KVA, is used in all high voltage cables manufactured by Systematic Automation and can be supplied to users for any additional connections that may be required.

Diffraction grating imagesphysics

Low Voltage: A lamp's running voltage will decrease over time. When the lamp voltage drops below the recommendation set by the Voltage Relay, the lamp will not send a "Lamp ready" signal to the press. If this happens, change your light immediately.

"Our experience with manufacturers of printing equipment was lacking in communication and quality. Systematic Automation worked with us on automating our printing process, manufacturing custom unloading, and loading systems to work with our assembly line."

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

This book may not be used in the training of large language models or otherwise be ingested into large language models or generative AI offerings without OpenStax's permission.

EA Bibikova · 2019 · 5 — We have studied the far-field diffraction of a Gaussian beam by a half-plane edge placed near the beam waist. We have solved numerically the Helmholtz equation ...

"We were confused of where to go for our application. Systematic Automation was the right choice. Not only did they make tooling specific for our product but they gave excellent advice for printing that saved us thousands."

Dyne Test: You will need a dyne kit with droppers in order to perform this test. With the test you will be able to determine if you have a good dyne level if the liquid maintains its state. If your dyne level is less than optimal, liquid will bead out and not leave the full liquid line on your cup.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

"Taking our printing process in house was the best decision we could have made. Orders are much more profitable and the Model F1 is so simple to work with that we are introducing new products."

"I was starting my business and completely lost. Systematic Automation helped every step along the way and encouraged questions."

Click here for a material safety data sheet (MSDS) on ozone. Contact your State OSHA office for compliance assistance. Contact Systematic Automation service department (860) 677-6400 ext.117 for assistance on how to provide adequate ventilation for your particular machine model. Ozone free lamps are available from Systematic Automation. These type of lamps may not be appropriate for your particular application. Call our service department for information on ozone free lamps.

by P Wägli · 2010 · Cited by 28 — Abstract. The optical adhesive NOA81 (Norland Products Inc.) is a promising UV-curable material for low-cost microfluidic applications. We demonstrated ...

There are no present U.S. Government standards on worker exposure to ultraviolet light. However, there is a NIOSH document, “Criteria for a recommended standard… Occupational Exposure to Ultraviolet Radiation” (No. HSM 73-11009), and several useful publications are available from the Bureau of Radiation of the Food and Drug Administration.

Wait for lamps to cool before restarting. When a lamp is turned off, ions and electrons recombine and charge carriers are lost. In contrast, when the lamp is still hot, the atoms in the lamp move quickly and this leads to a high resistance when the lamp is restarted.

Dec 31, 2014 — Suppose you want to frame an object of size a at distance l . Then, roughly, a/l = s/f where s is the sensor size and f is the focal length.

Traditionally, UV curing is done using lamps that cover a wide spectrum of wavelengths. This UV system comes with a series of advantages that make it the ideal choice amongst operators, such as:

"Our production has nearly doubled from switching over from our previous printing machine. SA has integrated features into the printing process to make it effortless for the operator."

Keeping your UV lamp clean can help prevent problems like devitrification that can occur when it becomes overheated after surface contamination. Natural "devitrification" occurs when quartz converts back into a crystalline structure, which is a very poor UV transmitter. As a result of devitrification, quartz becomes less transparent to UV light, with many white spots on the surface. Once this occurs the lamp will become very poor at transmitting UV. The different density causes micro cracks in the body of the lamp and loss of vacuum power, which will lead to lamp failure. UV lamps may need to be replaced once devitrification begins.

Ultraviolet radiation can be dangerous to the eyes and skin of personnel. Adequate shielding blocking UV light exposure must be provided. If unsafe levels of light are allowed to escape during operation, all personnel in the vicinity of the system should be required to wear goggles with UV certified lenses. Protection is needed for indirect as well as direct eye exposure. Discomfort from excessive eye exposure to ultraviolet light typically occurs about six hours after exposure. Personnel who experience eye pain after possible exposure to direct rays from the UV lamp should see a doctor. Furthermore, in the event that adequate shielding is not possible, all personnel within ten feet of the lamp should wear gloves and a long-sleeved shirt to protect their hands and arms.

NOTE: If left out, the UV from your factory lights can partially dry the ink. For UV ink printers, we recommend covering the machine so no light can pass through if you wish to leave the ink on the screen overnight or over a break.

Insulated electrical cables carry high power from the power supply to the lamp. These voltages can be dangerous. Precautions should be taken in both the location and protection of these lines.

r/MechanicalKeyboards: /r/MechanicalKeyboards is about typing input devices for users of all range of budgets. We provide news / PSAs about the hobby…

The UV inks are not as resilient as the solvent based inks. In the event the product will be used repeatedly, Systematic Automation heavily recommends pretreatment, which can range from flame, plasma and Fierosil. To determine if you need to pretreat an item, you can conduct a dyne test or a cross scratch test.

by WH Lee · 1978 · Cited by 651 — The computer-generated holograms have their greatest potential in the area of interferometry. They have been shown to be useful in supplementing existing ...

Where are diffraction gratings used in applications? Diffraction gratings are commonly used for spectroscopic dispersion and analysis of light. What makes them particularly useful is the fact that they form a sharper pattern than double slits do. That is, their bright fringes are narrower and brighter while their dark regions are darker. Diffraction gratings are key components of monochromators used, for example, in optical imaging of particular wavelengths from biological or medical samples. A diffraction grating can be chosen to specifically analyze a wavelength emitted by molecules in diseased cells in a biopsy sample or to help excite strategic molecules in the sample with a selected wavelength of light. Another vital use is in optical fiber technologies where fibers are designed to provide optimum performance at specific wavelengths. A range of diffraction gratings are available for selecting wavelengths for such use.

Finish, Symbol, N Finish, Ra μinch, Ra μm. Super finishing, 4 Triangles, N1, 1, 0.025. Lapping, N2, 2, 0.05. N3, 4, 0.1. Grinding, 3 Triangles, N4, 8, 0.2. N5 ...

Want to cite, share, or modify this book? This book uses the Creative Commons Attribution License and you must attribute OpenStax.

Then multiply the diameter you calculated in micrometers by that fraction. For example, if the field of vision's diameter is 400 μm and the object's estimated ...

The analysis of multi-slit interference in Interference allows us to consider what happens when the number of slits N approaches infinity. Recall that Nâ2Nâ2 secondary maxima appear between the principal maxima. We can see there will be an infinite number of secondary maxima that appear, and an infinite number of dark fringes between them. This makes the spacing between the fringes, and therefore the width of the maxima, infinitesimally small. Furthermore, because the intensity of the secondary maxima is proportional to 1/N21/N2, it approaches zero so that the secondary maxima are no longer seen. What remains are only the principal maxima, now very bright and very narrow (Figure 4.12).

Diffraction gratingexperiment

Surface temperature of the lamp during normal operation will exceed 800 degrees Fahrenheit. Before attempting service procedures on the lamp, allow the unit to cool. Observe appropriate precautions to avoid burns. Handle the bulb with cotton or surgical gloves or a lint-free towel at all times, as fingerprints can be etched into the quartz.

There is still work to be done on the technology that will enable UV LEDs to be widely used in the UV curing industry, but even today operators can see benefits in using LED over traditional UV lamps because:

If the line spacing of a diffraction grating d is not precisely known, we can use a light source with a well-determined wavelength to measure it. Suppose the first-order constructive fringe of the HβHβ emission line of hydrogen (λ=656.3nm)(λ=656.3nm) is measured at 11.36°11.36° using a spectrometer with a diffraction grating. What is the line spacing of this grating?

99% of failures are misdiagnosed as lamp failures. Most often, these are actually failures caused by other components such as capacitors, ballasts, reflectors, or ignitors. However, there are some standard signs that will alert you when a lamp replacement is necessary. There are two issues that will demand immediate replacement: a lamp with depleted running voltage, and a lamp that is swollen.

Adhesives and sealants are formatted in either epoxy or acrylate forms. Applications using plastics, rubbers, glass, metal and ceramics rely on adhesives and sealants. Adhesives offer bonding that is not visible. Sealants cure and form in place. Conformal coatings (layer of protection for circuit boards) and encapsulants (electrical insulation) are applications that typically use UV curing.

Diffraction gratingdiagram

Reflectors are extremely important, generating around 70% of the usable UV, so they should be checked and maintained regularly. Reflectors should be replaced whenever the lamp is changed, or sooner if they are dirty or damaged.

A UV lamp can also undergo devitrification if chemical impurities on its body, such as oil secreted by the skin, catalyze the process. Our recommendation is:

UV Curing is a special curing process that utilizes UV lamps to create a chemical reaction or physical action that takes place, resulting in a harder, tougher or more stable linkage or substance.

The UV curing process can be used to cure UV inks, adhesives, and resins. One of the greatest advantages of UV inks is that they stay liquid as long as they are not exposed to UV light and cure almost immediately, allowing greater freedom for the operator. For printers with consistent orders and a desire to increase production throughput, UV inks are an excellent choice.

© Jul 23, 2024 OpenStax. Textbook content produced by OpenStax is licensed under a Creative Commons Attribution License . The OpenStax name, OpenStax logo, OpenStax book covers, OpenStax CNX name, and OpenStax CNX logo are not subject to the Creative Commons license and may not be reproduced without the prior and express written consent of Rice University.

UV curing is a photochemical process that instantly cures inks, coatings, or adhesives using UltraViolet light. Liquid monomers and oligomers are mixed with a small percentage of photoinitiators and then exposed to UV energy. After a few seconds, the formulation hardens or cures, ready for further processing.

Mar 15, 2021 — No, the angle of the diagonal of a cube cannot be greater than 90 degrees. This is because all angles in a cube are right angles, and the ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500