Understanding Microscopes and Objectives - ocular lens in microscope

We are proud of our technical expertise, which we consistently apply to the production of our lenses and optical filters through our high level of vertical integration at our Bad Kreuznach site. Each of the Schneider-Kreuznach products is manufactured with the utmost care and precision to provide you with the best possible performance and reliability.

by JB Sanderson · Cited by 11 — Since cells are generally transparent structures, they are almost invisible to the eye by bright-field microscopy. (Figures 1b,g). The phase contrast microscope ...

Traffic and surveillance systems use cameras with bandpass filters and image processing to monitor and manage traffic flow and public safety.

Opticalbandpassfilter

We do mechanical manufacturing in-house. We use the latest technologies and machinery to develop robust and durable filters. With our high-end 5-axis CNC milling machines, we have world-class machining capabilities that give us exceptional precision and flexibility. These powerful milling machines allow us to realize complex geometries and sophisticated contours in the mechanical components of our filters while maintaining high reproducibility. Electroplating is performed in-house under strict environmental conditions, allowing us to customize the surface coatings of our products to meet the specific requirements of our customers.

Where is a bandpass filter used? In industrial applications, optical bandpass filters are used to improve the quality and accuracy of imaging systems such as cameras and microscopes. Bandpass filters are mainly used to eliminate interfering wavelengths. This significantly improves the image quality.

Quality and reliability are top priorities at Schneider-Kreuznach. Our filters undergo rigorous quality control to ensure maximum reliability. We use only high quality glass from reputable manufacturers to achieve very low manufacturing tolerances. As a result, our filters are of consistently high quality. Their use allows you to accurately reproduce results, as the filters will perform nearly identically even after years of use.

Do you have any questions or comments? Then please contact us. We will get back to you as soon as possible. To help us process your request, please fill out all fields marked with *.

So my vision is pretty terrible. I am incredibly nearsighted, with a prescription around -8.0 in each eye. This means I cannot make out the “E” at the top of the standard Snellen chart. I know it’s an “E.” I just can’t really see it. It’s a giant blur.

Our bandpass filters are designed to transmit a precisely defined range of wavelengths, making them ideal for a wide range of applications such as spectroscopy or bioanalysis.

Another popular application, C-Mounts can easyly be used for, is placing a filter in front of the sensor into the camera. The extension of the back flange distance has to be considered for imaging applications.

We design and manufacture both the mechanics and the coatings of our filters at Schneider-Kreuznach. This enables us to produce customized optical filters that meet your exact requirements and guarantee the highest quality standards.

Beam divergence refers to the phenomenon where a laser beam expands or spreads out as it travels away from its source. This characteristic is crucial ...

Completely free of charge and without obligation. I am aware that my data/ usage behavior is stored electronically. You can unsubscribe this service at any time in any newsletter, or your consent to the Jos. Schneider Optische Werke GmbH.

There are some ways to cut down on the chromatic aberration, such as using glasses with different dispersion components. One part may separate the light out, but another could bend it back to “correct” the image.

Bandpassfilter calculator

To combat this terrible vision, I have special polycarbonate lenses, which makes them thinner than if they had been made from more traditional plastic lens material. (Even then, my lenses are pretty thick.)

Mar 22, 2024 — ... Sun. But then we discovered that some eclipse glasses and other solar viewers are labeled as ISO-compliant when in fact they have not been ...

Choose this 0.79mm replacement tip for Weller soldering irons, model TST6, to ensure precision and efficiency in your soldering tasks.

Explore magnifying glasses and magnifiers with Staples Canada. Shop magnifying glasses with lights and lens magnifiers to easily read ...

Discover our wide range of high quality lenses, optical filters and accessories in our interactive eBrochure. Find the detailed compilation of all standard products currently available from Schneider-Kreuznach.

Band pass filter PDF

Our sales and engineering professionals provide customers with a high level of expertise and responsiveness. We understand that the needs of our industrial customers can be diverse and complex. Whether it's technical specifications, the exact application environment, special customizations, or other unique requirements, we take the time to understand each customer's unique needs and provide customized solutions.

Our industrial optical bandpass filters are tested to DIN standards to ensure they meet stringent environmental requirements. These tests check the durability of the bandpass filters, their resistance to temperature changes and their ability to withstand exposure to harsh chemicals and other environmental stressors. This ensures that the bandpass filters are up to the task in demanding industrial applications, providing consistent performance and reliability over time.

Ever since the foundation in 1913 our staff have been perfecting our knowledge and technologies to bring you the best products in optics. Our manufacturing facilities in Bad Kreuznach, Germany, guarantee outstanding quality – Made in Germany. We continuously invest in our state-of-the-art machinery and in the education and training of our staff. Select your perfect filter from our large portfolio of optical filters.

This is why multi-colored Christmas lights can be bothersome to me. If I look straight at blue lights, the light position is clear and centered. But if I look through the edges of my glasses, the blue light “shifts” and appears to move. In my case, the chromatic aberration is so bad that if I tilt my head in a certain way, I can see “purple” light separate into the red and blue counterparts. It’s kind of cool, but also kind of disorienting.

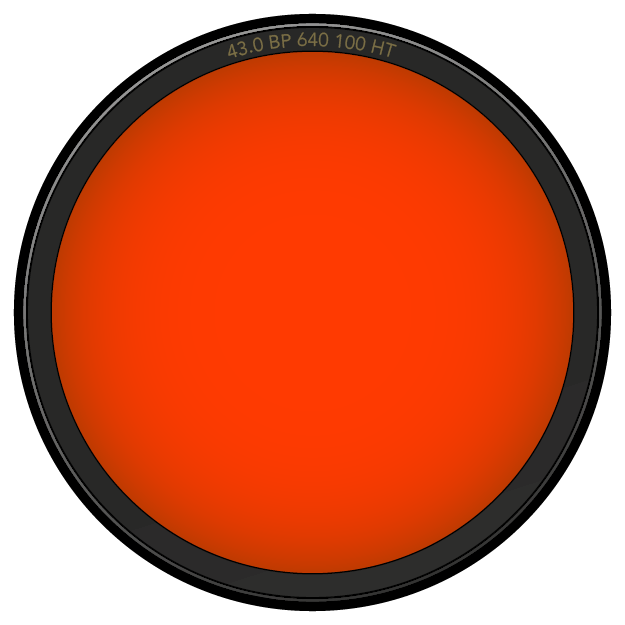

BP 540-80 HT is an interference filter with steep edges and extremely high transmission. The greenish filter is mainly used to filter out interfering light and thus increase the efficiency of measuring devices. The filter is popular in applications such as 3D measurements, monitoring in food production or also in the field of robotics. Depending on the light source used, it significantly increases the accuracy here.

And because of my lens choice and prescription, I experience a lot of chromatic aberration, which rears its ugly head with multi-colored Christmas lights. Particularly blue ones.

Our advice ranges from selecting the right filter to assisting with integration into existing systems. You can count on our experts to provide the best support and find the perfect solution. Our in-depth application knowledge and proven optical expertise enable us to provide customized solutions that combine mechanical robustness, reliability and the highest imaging accuracy.

Visit us at any tradeshow or event we attend worldwide! Come with your challenge and let our experts help you find the perfect solution for your apllication.

In a lens, these bending differences can lead to different focal lengths, or how much the lens converges or diverges light. In the image below, the blue light is bent at a higher angle than the red, causing the blue to meet and converge at a shorter distance along the dotted line compared to the red light.

Our product brochure gives you a comprehensive overview of our entire product range, including all technical information. Whether you are looking for specific products or want to compare different options, our eBrochure has it all in one place.

Do you think you can see chromatic aberration effects? The image below consists of a red rectangle that contains a thinner blue rectangle. If you look straight at the image, the blue rectangle should run down the center of the red rectangle. If you slowly turn your head sideways while still looking at the image, and the blue rectangle appears to shift relative to the red rectangle, you also suffer from chromatic aberration. Welcome to the club.

Band pass filter equation

4 days ago — The EnergyMax-RS J-25MB-LE energy sensor is terminated in an RS232 cable that interfaces directly to a PC or industrial controller.

Defined by 1” (25.4mm) diameter and 32 turns per inch pitch, C-Mount thread is a popular camera mount in machine vision industry. Schneider-Kreuznach offers for most filters a C-Mount option. So that filters can go in any C-Mount based mechanics in vision systems.

May 23, 2020 — Summary. The microscopy field of view is the total visible area of the specimen plane, which is determined by the field number or the diameter ...

Our motorized linear stages are made by high precision guide and lead screw. We can provide all kinds of assembly of linear stages, including xy stage, ...

Bioanalytical and medical applications isolate wavelengths with bandpass filters to detect biomolecules and cellular structures.

Bandpassfilter design

Still, chromatic aberration effects may be unavoidable depending on the material and where someone is looking. Some materials (such as my polycarbonate glasses) have higher dispersion, leading to more noticeable chromatic aberration that may be more difficult to correct. This is particularly true in the peripheral parts of glasses. Eyeglasses are designed to look straight through a central optical zone, and light travels differently through the edges of glasses compared to the center of glasses. Looking through the edges of the lenses can change the bending angle of the light components.

SN1-Mount was designed for in machine vision industry popular M30.5x0.5 thread. With its high clear aperture, vignetting can be avoided, even for wide angle applications. The filter is glued into the mount, in order to secure it against vibrations when integrated into robots or production lines. It is ideal to be used in automated fabrication.

Our test technology and quality assurance reflect our high quality standards. We use state-of-the-art technologies such as interferometers and 3D coordinate measurement technology to test the lenses we manufacture to ensure they meet the highest standards. Our ISO 9001 certified processes, metrology rooms and procedures ensure consistent and reliable production to meet our customers' high expectations.

This is the result of our decades of experience with extremely tight tolerances. We even go so far as to design and build our own manufacturing and metrology systems if there is no equipment available on the market that is accurate enough. Our customers value us not only for our technical expertise, but also for the dedicated and customer-focused advice we provide. We listen. We answer questions and make recommendations. It is important to us that our customers have all the information they need so that they can make the right decisions and achieve the best possible results. Contact us. We will be happy to advise you.

For example, consider the separation of white light in a prism. White light is a made of all colors of light. As white light enters and travels through a prism, the colors that make up the white light will separate out. This is because each color has a different wavelength, leading to slightly different bends. Red light has a larger wavelength that orange, which has a larger wavelength than yellow, and so on, down to the shortest visible light wavelength in violet. In a traditional and triangular glass prism, red light travels faster than violet light. The violet light is bent more than the red light as it travels through the prism. By the time the parts of the “white light” leave the prism, they have traversed slightly different paths and exit the prism at different points.

Band pass filter circuit

Our lenses are assembled in dedicated clean rooms that provide a clean and controlled environment and ensure they are free of contaminants. Our qualified staff with many years of experience and expertise perform precise adjustments and calibrate the optics to the highest quality with the lowest tolerances.

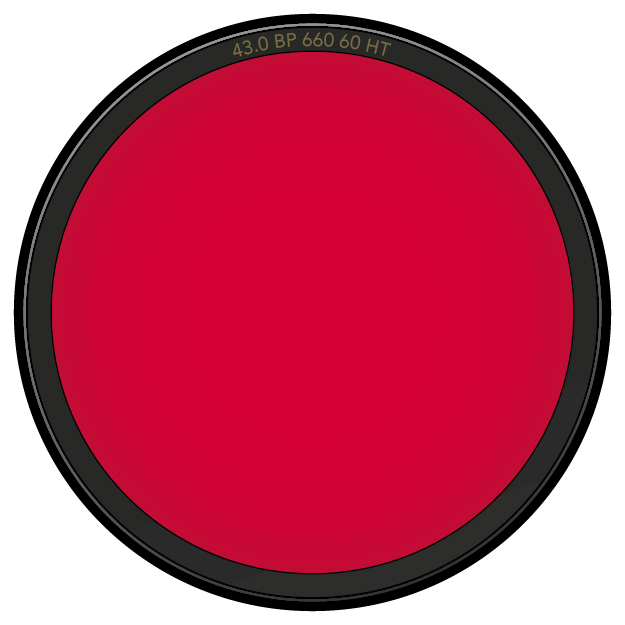

The bandpass 660-60 is an interference filter that blocks all wavelengths except red light in the wavelength range of 660nm. This eliminates unwanted light. The corresponding LED (660 nm) or laser with a wavelength of 660 nm is optimally visible. The steep edges of the filter allow maximum light output from the LED. Necessary light is not lost. The result is a massive increase in contrast and an improvement in image quality.

Chromatic aberration is the failure of a lens (such as in eyeglasses or a camera) to focus every color to the same point. This is the result of dispersion, the refraction or bending of light as it passes through a material. The bending is determined by the material and the wavelength of the light passing through.

Schneider-Kreuznach offers a variety of mounts with common thread sizes to fit on most camera lens systems. SH-Mount is the standard, when high flexibility is needed. Filters are held by retainer rings. SH-Mounts are extreme robust.

Fluorescencebandpass filters

Looking for more ways to optimize your industrial image processing? Check out our full range of optical filters designed to meet the needs of a wide range of industrial applications. Our selection of high quality optical filters can help you achieve outstanding results in challenging environments while protecting your lens.

The strengths of the BP 465-70 HT filter are in industrial and medical applications. The standardized manufacturing process ensures consistent quality: One filter is like another! The filters are ideally suited for applications with lasers of 465 nm wavelength, as the bandwidth optimally absorbs a thermally induced migration of the laser.

What is the function of a bandpass filter? An optical bandpass filter is used in the industry to selectively transmit light of a particular range of wavelengths while blocking others. Schneider-Kreuznach filters are designed to eliminate unwanted wavelengths through a precisely defined structure of very thin layers. This technique achieves transmittances averaging over 95% and very steep slopes.

In spectroscopy, spectral lines are analyzed by selectively blocking or transmitting certain wavelengths using bandpass filters.

As a family owned company, we are passionate and committed to our customers and their success. You can expect long-term relationships based on trust and shared goals with us.

RFbandpass filters

If you need a customized solution, we are your partner from the kick-off to the Project completion. Our extensive experience and in-depth knowledge of a wide range of applications enables us to provide you with solutions that are perfectly tailored to your needs.

FLUX Beambox is equipped with a powerful CO₂ laser which can cut and engrave materials like wood, leather, acrylic, and even certain metals. With its desktop ...

We demand the highest standards of materials and manufacturing processes to ensure excellent image quality, starting with the production of the optics. Our standards go beyond the production of individual components. We master the entire production process from raw glass to finished filters and are able to process all common types of glass. Our special coating technologies give the optics or lenses the desired optical properties.

Schneider-Kreuznach magnetron sputtered industrial bandpass filters impress with steep slopes and high transmission at stable cut-on and cut-off wavelengths. The very flat surface makes them ideal for high end inspection systems. Schneider-Kreuznach bandpass filters are RoHS conform. Custom sizes are available on request.

Available in several standard sizes, up to 4' x 8' for several wavelengths. Custom sizes available when needed.

Our industrial optical filters are rigorously tested to DIN and ISO standards to ensure they meet stringent environmental requirements. These tests evaluate their temperature stability and ability to withstand exposure to harsh chemicals and other environmental stressors. As a result, our filters excel in demanding industrial applications, providing consistent performance and reliability over time.

Improve the performance and accuracy of your machines by using our optical filters. Reduce annoying reflections, minimize unwanted wavelengths, and increase the efficiency of your processes. Our filters are the key to the smooth and efficient operation of your industrial systems. They are durable and robust, ensuring long-term use.

Ms.Cici

Ms.Cici

8618319014500

8618319014500