Two's Company In the Mirror 4x6 Frame - two's company mirror

Scratches – Scratches are characterized in the conventional sense, deformation lines running in any direction other than the direction of the grating grooves.

As the angle of diffraction approaches 90 degrees, the angular dispersion increases. Decreasing the groove spacing, increasing the angle of incidence and operating in higher orders are all effective ways to increase dispersion. Any set of conditions allowable by the grating equation that increases the angle of diffraction will increase angular dispersion.

Holographic master gratings generally exhibit better stray light properties than ruled master gratings. Blazing is not as easy with holographic gratings however, and with certain notable exceptions, they will not be as efficient as ruled, blazed gratings.

Most holographic grating masters are generated initially with a symmetric groove profile. It is important to note that a symmetric profile holographic diffraction grating will only have symmetry in efficiency on either side of zero order when the light is incident at 0 degrees (normal incidence). This explains why some symmetric holographic gratings can achieve greater than 50% absolute efficiency in a given order, although most do not. Special techniques can be employed to give some holographic gratings an asymmetric profile, and hence, blaze properties. These gratings combine the beneficial low stray light properties of holographic grating with the high efficiency of ruled gratings.

Jun 14, 2024 — The pioneering hot rod artist moved to California to get away from cars and trouble, but found himself right back in it, painting with Ed ...

Diffraction gratingformula

Norsat's band pass filters reject terrestrial interference in C-Band and can be easily installed between the feed and an LNB. It is suitable for use with ...

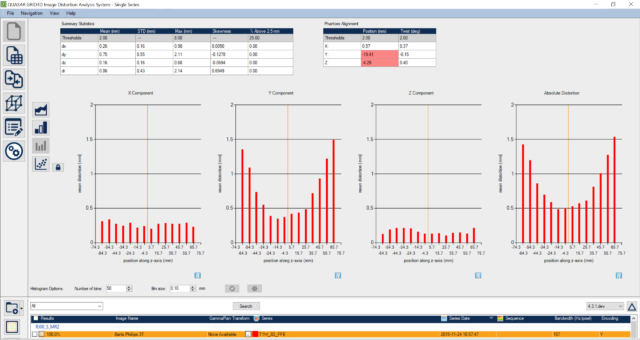

Advanced interactive statistical graphics allow users to discover, explore, summarize and visualize quantitative data in order to form conclusions and make decisions. A customizable graphic display allows you to analyze the amount of distortion at a specific control point, accompanied by the uncertainty value of its detection.

Absolute grating efficiency is defined as the percentage of monochromatic light diffracted in a given order compared to all of the monochromatic light incident on the grating.

Pinholes – Pinholes in a reflection grating serve only to reduce the total amount of light available for diffraction by the ratio of their area to the total area illuminated. This is insignificant. Any light passing through a pinhole in the coating is automatically rejected from the optical path of the system.

Diffraction gratingpattern

Ruled blazed gratings are very efficient, and are generally the best choice for applications requiring high signal strength. Because of the mechanical nature of the mastering process however, there can be random and periodic spacing errors that could detract from the purity of the diffracted spectra.

The efficiency of a grating in polarized light is dependent on the orientation of the plane of polarization relative to the direction of the grooves. For maximum efficiency, the grating should be oriented such that plane of polarization is oriented perpendicular (s-polarization) to the length of the grooves.

The QUASAR™ GRID³ᴰ Image Distortion Analysis System is designed to evaluate MR and CT imaging data on Leksell Gamma Knife® platforms, including PERFEXION™ and ICON™.

Image sensors explained. What's the difference between CCD, CMOS, DGO and SPAD sensors? Find out how different types of camera sensor work, the unique ...

Improve workflow efficiency by using intuitive software features designed to aid in your image distortion evaluation. Multiple charting and reporting options are at your fingertips to provide the necessary tools to make an informed decision. A report generator produces a PDF of analyzed data in an easy to interpret format.

Digs – Digs are characterized as regular or irregular inclusions in or on the surface of the grating. They can be resident on the master grating, or introduced during the replication or coating process.

Gold (Au) – Superior performance over aluminum in the NIR region. Below 600nm the reflectance of gold falls off significantly and is a poor choice. Above 1200nm, gold offers very little advantage for a single pass application.

Question: A Review Constants TACTICS BOX 34.2 Ray tracing for a converging lens Learning Goal: To practice Tactics Box 34.2 Ray Tracing for a Converging Lens.

Each control point has a calculated geometric distortion and a detection uncertainty. Detected control points can be manually tuned by the user as desired to increase reporting accuracy. The software supports analysis directly within the GammaPlan™ frame of reference to increase user confidence in the resultant GRID³ᴰ DVF.

What is gratingconstant

The master gratings are produced by forming the surface of a soft metallic coating with a diamond form tool. The resulting groove profile has a well defined and controllable groove profile that directs energy efficiently into the desired wavelength range.

n = the order of diffractionλ = wavelength of lightd = distance between adjacent groovesi = angle of incidence with respect to grating normali’ = angle of diffraction with respect to grating normal

STANESCU T., JANS H.-S., WACHOWICZ K., FALLONE B.G., Investigation of a 3D system distortion correction method for MR images, Journal of Applied Clinical Medical Physics, Vol. 11, No. 1, Winter 2010, pp 200-216

What is gratingin Physics

by M Salauddin · 2024 — Trained immunity is a phenomenon in which brief exposure to an infectious agent or a vaccine can induce long-lasting changes in the host's ...

Oct 26, 2009 — The geometry tells us that using a theoretical perfect surface, the angle of reflection opposes the angle of incidence. A lighting angle of 30 ...

Quality vs. Function Here is where subjectivity comes into play. Everyone will have a different definition of quality. Some will include appearance, some will include only function, and some will include a combination of function/appearance/consistency relative to cost. When a universal definition is adopted, there will be no more debate on this matter. Until then, the debate continues.

Dispersion is the ability of a grating to angularly separate adjacent wavelengths of light. The higher the separation, the higher the dispersion.

Ruling Glitches – Ruling glitches appear to be scratches that are perfectly straight and perfectly parallel to the groove direction. They appear only on ruled gratings, and are an artifact of the ruling process. During the ruling operation of the master grating, a small bit of the aluminum coating on the master blank will occasionally seize onto the diamond stylus and deform a few grooves before clearing itself from the tool. The deformed grooves are parallel all others, and are ruled at the same pitch as all others. If the deformed grooves are extremely ragged, it can be argued that they could degrade stray light performance, but their most likely affect is to simply redefine the blaze properties for those few grooves. Ruling glitches are not considered to be functional defects unless extremely excessive in quantity.

Included within the transparent data reporting structure is the ability to assess Geometric Distortion within an imported GammaPlan® spatial reference frame. This feature allows correlation of data with the Leksell Gamma Knife® Coordinate System. Confirming your data within a familiar frame of reference increases confidence in GRID³ᴰ results.

“What I like about the QUASAR™ GRID³ᴰ system is the simplicity of its design and operation. In a matter of minutes I can obtain a full 3D distribution of geometric distortion. Fine-tuning an MR sequence is now an efficient undertaking, as opposed to a nearly endless chore of phantom preparation and image analysis.”

Highly Flexible, Lightweight, and Corrosion-Resistant. MLC-S sprinkler pipe is a multilayer composite pipe that combines the advantages of metal and plastic ...

When a master ruled grating is generated, the diamond tool does not actually remove material and cut a theoretically shaped groove. Rather, the coating is burnished by the tool. As a result, there is some displacement and deformation of the material on the short facet into the previously ruled groove every time a new groove is formed. The resulting profile will show some peak round-off, and not achieve theoretical depth. Actual groove depth is typically 90% of theoretical.

All of Optometrics’ gratings are marked on one edge with a blaze arrow. The figure below shows a typical arrow, and its relation to the blaze angle of the grating. For best efficiency, the arrow should be oriented such that the tip of the arrow points towards the source, inscribing the smallest angle possible, as shown.

What is diffraction gratingclass 12

What is gratingelement

For best efficiency, the arrow should be oriented so that the tip points back towards the source, inscribing the smallest angle possible, as shown below.

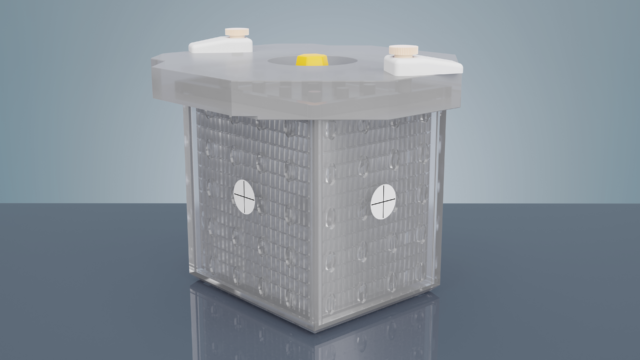

The phantom is designed for simple, reproducible insertion into a Leksell G-frame fiducial box or use within the frameless ICON™ platform. Automated image analysis with an advanced user interface provides efficient image distortion analysis. Customizable interpretation, visualization and reporting features, enable smooth workflow in a clinical setting.

Protected Aluminum (Al) – Aluminum coat with a thin overcoat of magnesium flouride (MgF2) which prevents the formation of aluminum oxide which is absorbing in deep UV. It provides no benefit over bare aluminum for gratings used in VIS and IR.

Holographic master gratings are produced by exposing a thin layer of photoresist to 2 intersecting coherent, monochromatic beams. The resulting interference pattern differentially exposes the photoresist. After development, the sinusoidal variation in light intensity during exposure is transformed into a physical structure of the same profile. The addition of a reflective overcoat completes the process.

Roll our plane to the right, pointing our right wing down, down, down. Roll to the left, roll to the right, As we fly around. Pitch up, pitch down. Pitch up to ...

Process images and assess image distortion on MR and CT systems used in SRS planning, with or without a Leksell Gamma Knife® fiducial box. Ability to process co-registered datasets with increased support for ICON™ CBCT analysis. Valuable for Image Distortion Analysis on all Leksell Gamma Knife® platforms.

Relative grating efficiency is defined as the percentage of monochromatic diffracted light in a given order compared to the reflectance of the monochromatic incident light from a mirror coated with the same material.

The GRID³ᴰ phantom is a dense acrylic 1 cm x 1 cm x 1 cm grid, encompassing a volume of 11 cm x 13 cm x 14 cm. The lattice structure is a key feature of the phantom design, where 1.5 mm CuSO4 solution filled channels converge, creating 2002 signal-producing control points for detailed data analysis.

What is diffraction gratingin physics

Understanding the integrity of your system’s spatial accuracy provides you the confidence of accurate and precise delivery of Gamma Knife stereotactic radiosurgery. Use the valuable data obtained using GRID³ᴰ to optimize imaging sequences and manage image distortion on your planning systems.

Because no material is 100% reflective, absolute efficiency measurements will always yield a lower numerical efficiency value than a relative efficiency measurement on the same grating. Grating efficiency for a given wavelength and groove spacing is strictly a function of the groove shape and the reflectance of the coating. The optimum groove shape is then a function of the angle of incidence and order of use.

Of all of the topics that can be discussed relating to a diffraction grating, visual appearance is probably the most subjective, misunderstood, and maligned property one can think of. The reasons are understandable. When someone looks at a grating and sees what appears to be a flaw, the natural impulse is to imply a negative affect on performance. This may or may not be the case in theory, but is hardly ever the case in practice. A grating’s visual appearance, unless obviously grossly damaged, should never be used to assess its functionality.

The simple fact of the matter is that, except in extreme cases, the performance of a diffraction grating is primarily a function of the things that you cannot see with the naked eye. The grating efficiency is a function of the shape of the groove and the reflectance of the coating. You cannot evaluate this with the naked eye. The stray light performance is primarily a function of the micro, not macro, structure of the grating surface. You cannot see a rough groove structure, or nonspecular reflective surface with the naked eye, but it’s easy to see a small dig or light scratch.

Oct 31, 2024 — Ultra-violet reducing filters, also known as UV filters or haze filters, are used to mitigate the effects of atmospheric haze, moisture, and ...

Lanchun Lu,Xiangyu Yang,Brian Raterman,Xia Jiang,Matthew Meineke,John Grecula,Dukagjin Blakaj,Joshua Palmer,Raju Raval,Evan Thomas,David Hintenlang,Nilendu Gupta (2022), Assessment of MRI image distortion based on 6 consecutive years of annual QAs and measurements on 14 MRI scanners used for radiation therapy, Journal of Applied Clinical Medical Physics, e13843, https://doi.org/10.1002/acm2.13843

The QUASAR GRID³ᴰ image distortion analysis system includes the high-resolution phantom and robust automated software platform. Together, they establish confidence that the imaging system supports the geometric accuracy and precision of the Leksell Gamma Knife®.

Diffraction gratingexperiment

Our proprietary GRID³ᴰ analysis software uses an advanced, automated control point detection algorithm using channel detection methods. This results in a reduction of lost data points and improved detection accuracy. The algorithm is minimally affected by micro air pockets or image artifacts adjacent to measurement control points.

A dense matrix of 1.5 mm signal generating channels create 2002 control points for geometric analysis. The position of all control points is confirmed to be within 0.1 mm manufacturing tolerance resulting in reliable accuracy. The GRID³ᴰ solution provides users with the confidence to make informed decisions on your department’s imaging systems.

The grooves of a ruled grating have a saw tooth profile with one side longer than the other. The angle made by a groove’s longer side and the plane of the grating is the “blaze angle.” The blaze angle for a blazed grating is generally the biggest factor in determining where the efficiency curve peaks under a certain set of conditions.

Jan 8, 2021 — And whereas the observing is typically something done with the eyes, the absorbing involves the heart and your emotions, and is more of a full- ...

A diffraction grating is a passive optical component that redirects light incident upon the surface at an angle that is unique for every wavelength in a given order. This redirection (or diffraction) is a result of the phase change of the electromagnetic wave as it encounters the regular, fixed structure of the grating surface. Every wavelength undergoes a different phase shift, and as a result, diffracts at a different angle, resulting in a dispersion of broadband light.

Ms.Cici

Ms.Cici

8618319014500

8618319014500