Top 12 Handheld Magnifying Glasses - magnifying glass best

Molybdenum is a refractory alloy with high heat conductivity and high melting point that exhibits almost no warping due to localized heating by the laser. These ultra-thin molybdenum pinholes have a laser damage threshold of 75 MW/cm2 CW and are suitable for pulsed laser use up to 700 mJ/cm2.

We also manufacture custom-designed PETG packaging containers in house. Customized packaging offers increased levels of safety and reduces the risk of defects caused during shipment. By holding the optics around their edges, this type of packaging maintains the surface quality and appearance of the components. Custom packaging is available as single- or multi-cavity, and is designed from low out-gassing material. To further optimize the PETG packaging, we can mold the customer name, program name and/or part number directly onto the packaging.

Best way to cleanoptics

Controlled environments such as cleanrooms are ideal for avoiding contamination when packaging sensitive optics. For the most demanding optics applications and customers, we inspect optical components under a flow booth, then vacuum-seal them in a nitrogen-purged ultra-low outgassing (ULO) bag. This ensures that the components remain clean and coating-ready throughout the shipping process.

Customers who have slightly less precision requirements often choose this tier. We will utilize ultrasonic cleaning, and will then pack the components in standard packaging in a non-cleanroom environment.

Our dedication to delivering clean and contamination free optics allows coating customers to process optical substrates directly from Sydor Optics as coating-ready optics.

The 910PH high energy pinholes are mounted in a 0.875-20 threaded housing making them compatible with our 910A five-axis spatial filters.

Optical wedges with ± 10 arc seconds of wedge angle tolerance. Superior craftsmanship made to your specifications in a variety of shapes, sizes, and materials.

Bestcleaning system for critical optics

Sydor Optics further improves the cleanliness and minimizes the potential for surface defects on the optics we manufacture by utilizing an automated 3-station Elma ultrasonic cleaning system immediately following the double-sided polishing process to ensure removal of all polishing compounds.

Utilizing programmable ultrasonic cleaning at every stage of polishing plano optics, Sydor Optics strives to save customers time and cost by supplying clean, packaged optics that are ready for use in an optical system or to be coated.

When a project requires the highest levels of precision cleaning and protection, customers will typically opt for Tier 1. We will provide ultrasonic cleaning, inspection, and vacuum packaging within our full cleanroom environment with cleanroom compatible packaging materials.

Our 0.875-20 threaded high-energy pinholes are fabricated from ultra-thin molybdenum, a refractory alloy with high heat conductivity and melting point. This material exhibits almost no warping due to localized heating by the laser. A smooth hole with extremely low ellipticity is produced using laser drilling techniques.

Our 0.875-20 threaded high-energy pinholes are fabricated from ultra-thin molybdenum, a refractory alloy with high heat conductivity and melting point. This material exhibits almost no warping due to localized heating by the laser. A smooth hole with extremely low ellipticity is produced using laser drilling techniques.

Physicsto break up or bend by diffraction. back formation from diffraction 1795–1805. Collins Concise English Dictionary © HarperCollins Publishers::.

Motorized Plantation Shutters. Sort by. Featured, Best selling, Alphabetically, A-Z, Alphabetically, Z-A, Price, low to high, Price, high to low, Date, ...

A triangular prism is ageometric solid with two bases that are congruent (identical), parallel triangles and all other faces are parallelograms. It is referred ...

We continue to invest in state-of-the-art equipment to ensure we meet the unique needs of each of our customers. To learn more about our precision cleaning and packaging services or to work with us on your next project, contact us today.

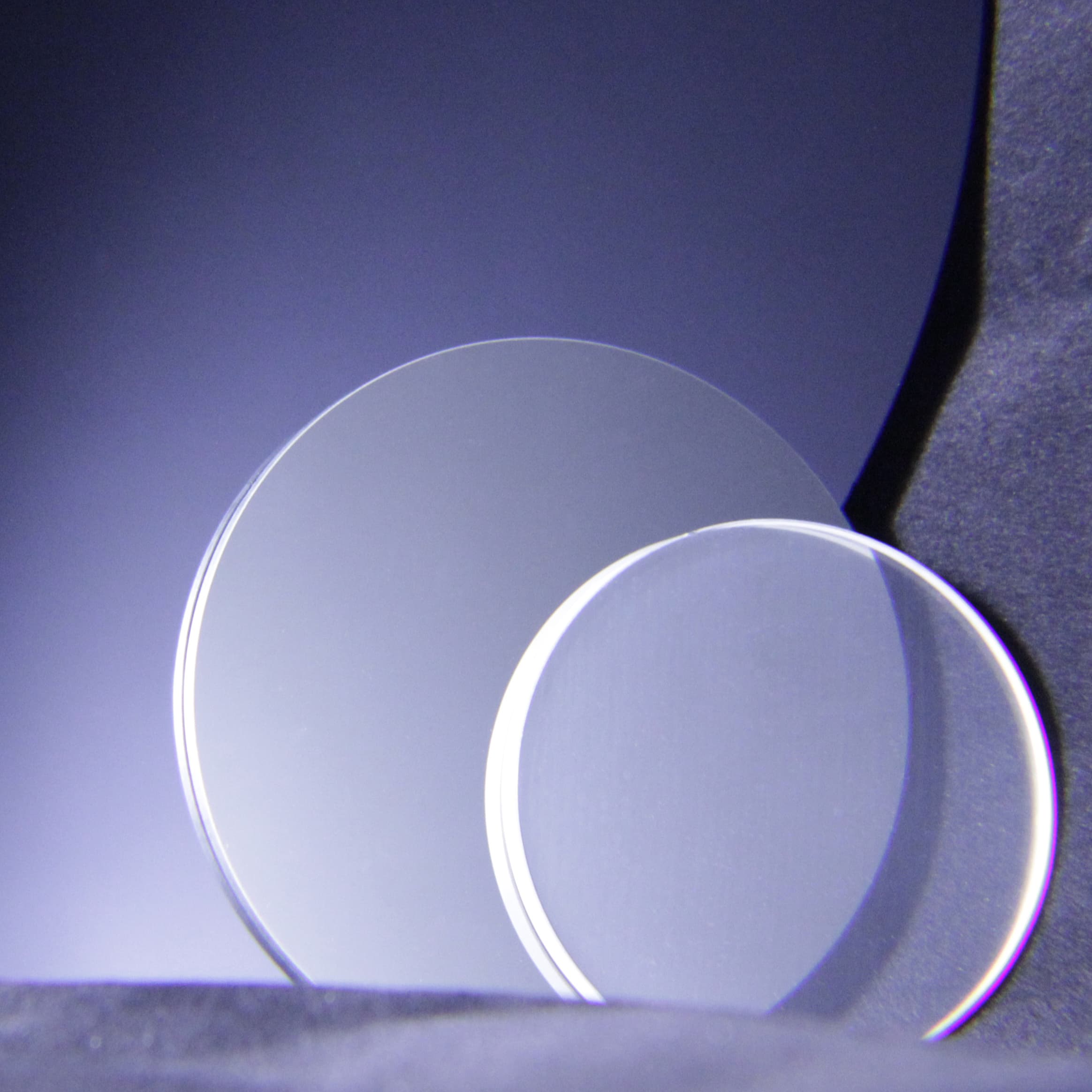

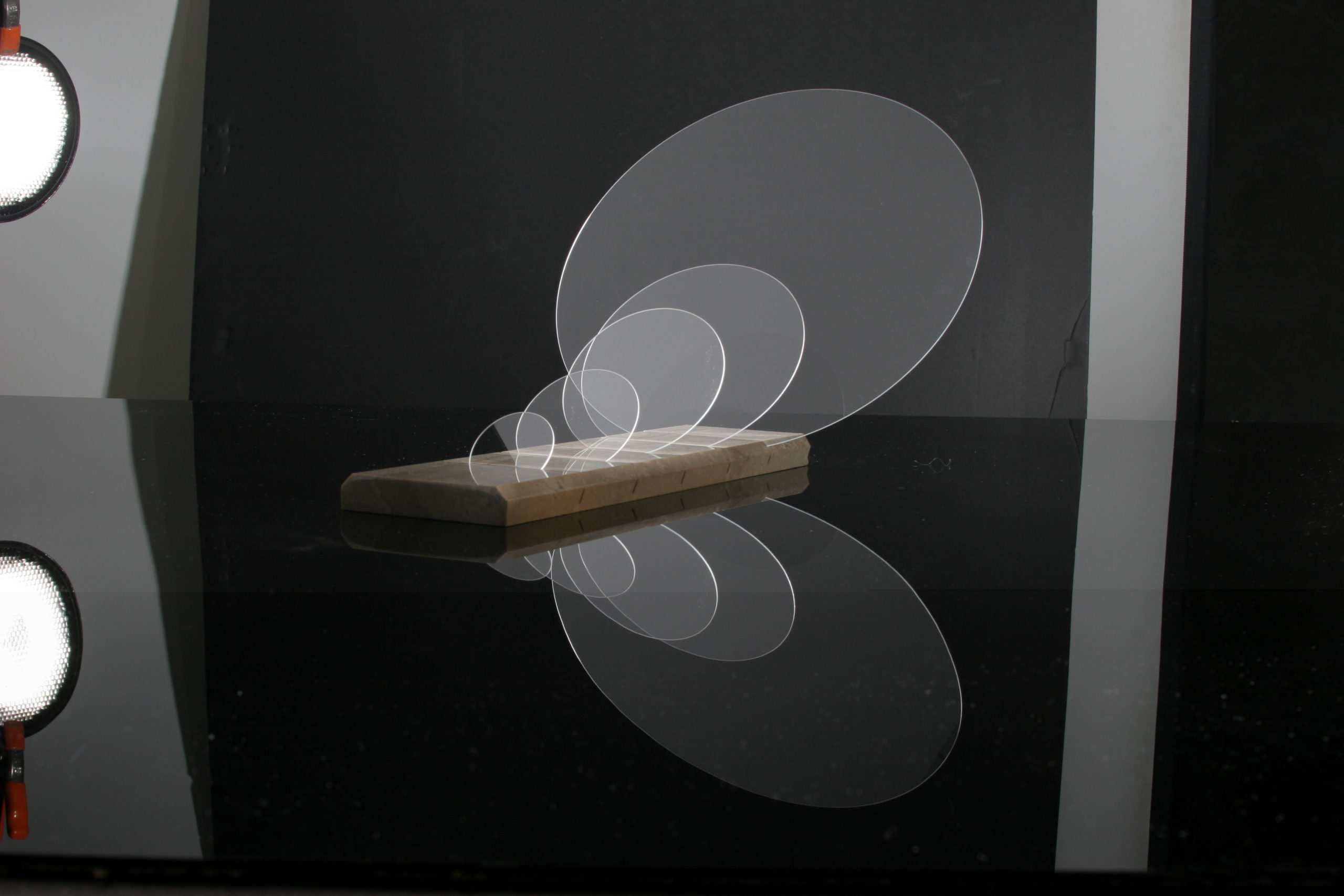

Reflect and transmit any combinations of wavelengths with precision plate beamsplitters. UV, VIS, or IR, Polarized or Unpolarized, 10:90 – 90:10 Reflection:Transmission(R:T).

NCI's Dictionary of Cancer Terms provides easy-to-understand definitions for words and phrases related to cancer and medicine.

Infrared (IR) light is used by electrical heaters, cookers for cooking food, short-range communications like remote controls, optical fibres, security systems ...

These 0.875-20 threaded pinholes can also be mounted in LP Series Multi-Axis Lens Positioners, 2-axis LP-05A-XY, 3-axis LP-05A-XYZ and 5-axis LP-05A.

How to clean dichroic mirror

We utilize spin-rinse dryers to rinse and dry stainless steel cassettes of wafers. The dryer will rapidly spin the wafers while injecting de-ionized water, fully rinsing any particles that may remain on the wafers. Once the wafers are thoroughly rinsed, the spin-rinse dryer will begin drying them by flowing heated nitrogen while the wafers continue to spin.

We designed the Ghost FX Filter to recreate the effect of a long exposure shutter lag, producing a ghosting / motion blur / replicating effect within your ...

To ensure we meet the needs of every customer, we offer a range of packaging options suited to the specific size, shape and protection needed including:

Yes, opt-in. By checking this box, you agree to receive our newsletters, announcements, surveys and marketing offers in accordance with our privacy policy

The 910PH high energy pinholes are mounted in a 0.875-20 threaded housing making them compatible with our 910A five-axis spatial filters.

USB-A, USB-B, 1996/1998. USB 2.0, 480 Mbps, USB-A, USB-B, Mini-USB B, Micro-USB B, 2000. USB 3.0, 5 Gbps, USB-A, USB-B, Micro-USB B, 2008. USB 3.1, 10 Gbps, USB ...

Best practices suggest that when coating or setting up an optical component, it’s best to use a witness sample, also called a “test piece,” to ensure that the actual part will match your specific coating specifications and your application.

Ultrasonic cleaning eliminates issues associated with mechanical cleaning techniques, which may cause streaks and scratches to the optical surface. Ultrasonic cleaning can significantly improve the cosmetics of the optics. At Sydor Optics, our ISO Class 7 Cleanroom contains two ultrasonic cleaning systems: an automated 8-station Elma ultrasonic system with a maximum capacity of 18 inches, and a manual 4-station system with a maximum capacity of 8 inches.

Gillette Series Moisturizing Shave Gel is formulated with glycerin to hydrate & moisturise, and deliver protection and comfort you need for healthy looking ...

These 0.875-20 threaded pinholes can also be mounted in LP Series Multi-Axis Lens Positioners, 2-axis LP-05A-XY, 3-axis LP-05A-XYZ and 5-axis LP-05A.

Compressed Airfor optics

Sydor Optics manufactures IR windows utilizing a range of infrared materials suited for the NIR, SWIR, MWIR and LWIR spectrums ranging from 0.75µm to 15µm for applications including thermal imaging, mineral & gas detection and monitoring and other forward-looking infrared (FLIR) imaging applications.

Choose products to compare anywhere you see 'Add to Compare' or 'Compare' options displayed. Compare All Close

When an application does not require precision cleanliness, Tier 3 provides high-quality standard hand cleaning in a non-cleanroom environment.

Cleaning plays a vital role in the manufacture of precision optics, as even a small amount of dust, debris or residual polishing compound can impact the end use of the optics or any subsequent coating process. Contaminated glass optics may affect throughput of the optical system in which they are utilized. To prevent these problems, consistent and thorough cleaning is imperative throughout the manufacturing process. At Sydor Optics, our precision cleaning and packaging services enable us to consistently deliver high-quality optics that are ready for use in an optical system or to be coated.

At Sydor Optics, we are dedicated to saving our customers time and money by streamlining the optics manufacturing and shipping process. Through the use of multiple automated ultrasonic cleaning systems we consistently provide clean optics that surpass customer expectations.

Spin-rinse drying works with our ultrasonic cleaning systems as a secondary operation, ensuring optimal cleanliness levels. We offer spin-rinse drying for wafers sized 100, 150, and 200mm.

Molybdenum is a refractory alloy with high heat conductivity and high melting point that exhibits almost no warping due to localized heating by the laser. These ultra-thin molybdenum pinholes have a laser damage threshold of 75 MW/cm2 CW and are suitable for pulsed laser use up to 700 mJ/cm2.

Aside from standard size glass wafers such as 100mm, 150mm, 200mm and 300mm, Sydor Optics can provide custom wafers with diameters up to 450mm and thin wafers with thicknesses down to 0.1mm.

Lens Distortions® assets are the preferred choice of top creators. For more than a decade, our assets have helped top creators turn their creative vision into ...

You can also treat yourself to some of the most stylish eyewear on the market — from modern to classic designer glasses and prescription glasses. A blue light ...

Ultrasonic cleaning utilizes cavitation, a powerful process that scrubs the surface of the glass at a microscopic level. This type of cleaning system is quick and efficient, easily cleaning hard surfaces. In addition to its efficiency, ultrasonic cleaning is more consistent, safe, effective, and environmentally friendly than solvent-based cleaning.

Ms.Cici

Ms.Cici

8618319014500

8618319014500