Fjord Spot Modern Adjustable Spot Light ... - spot lighting design

Backlightsrl

Large PartsSince images are built in pieces, high-resolution images can be captured and transferred more quickly than an area camera of similar size. For example, a KEYENCE line scan camera can capture images up to 67 MP at speeds of 6.1 μs/line. Additionally, lighting is much easier. Only one line across a large part needs to be illuminated at once, rather than the entire target.

This differs from our BX/CX Series which falls off in uniformity when configuring units larger than 16 inches in width but provide minimal edge effect and a thinner package.

Line scan cameras build 2D images one line at a time, sort of like a scanner, and are useful when images of large products, cylinders, or continuous webs are needed. Either the camera or part must be in motion during capture.

Your goal in this exercise is to write a function that takes in an image and a list of templates, and returns a list of the best fit location (bounding box) for ...

IPXY. Uploaded by. Sheyla Maza. 0 ratings0% found this document useful (0 votes). 53 views. 1 page. Document Information. click to expand document information.

Line scan cameras are used to capture images of moving parts one line at a time. Individual lines are stacked one atop the other in an image processing unit to ultimately build a 2D image. This style of image capture makes line scan particularly well-suited to inspections of continuous webs, cylinders, and large parts. Read on to find out why, or click here for more information:

Backlight lightingphotography

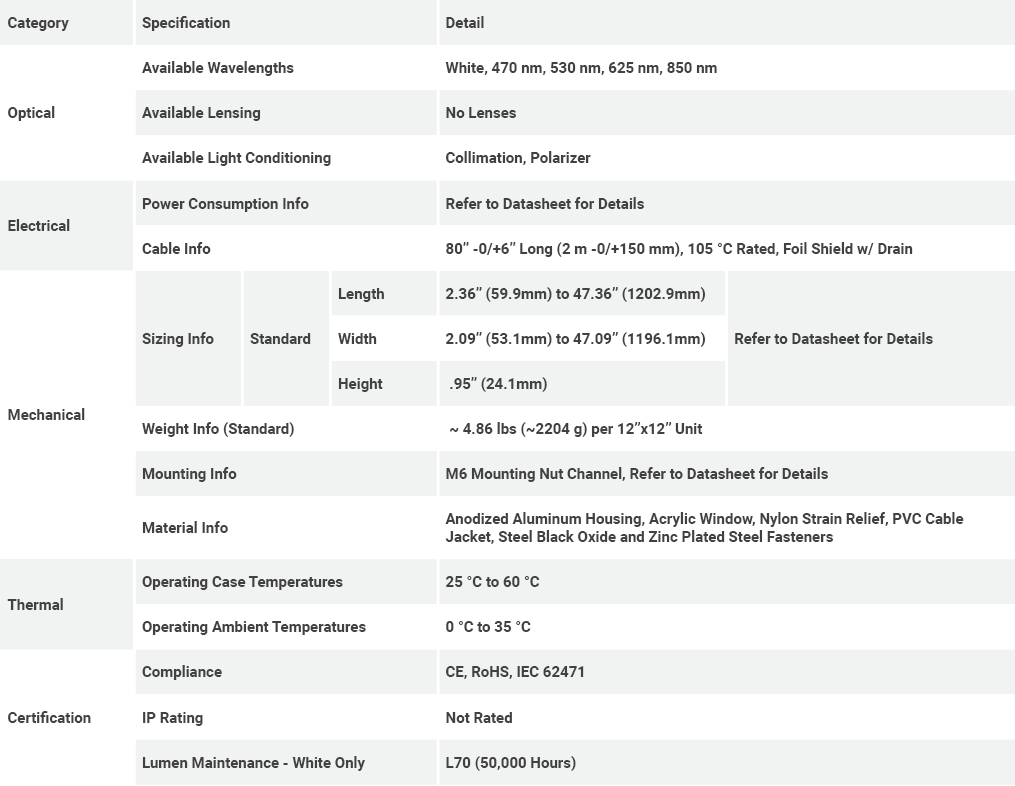

LightLight selection is critical to any machine vision configuration; what the camera can't see, a machine vision system cannot inspect. The shape, size, and color of lighting, as well as installation distance and angle, can all be optimized to emphasize the features being inspected, and prevent any influences by the surrounding environment.

20121212 — A headset that gives you a 360-degree field of vision. Called FlyVIZ, the system was designed by Jérôme Ardouin and colleagues at the Grande École d'Ingenieurs ...

2023131 — A cleaned stamp can also mean one from which a cancellation has been removed, making a used stamp appear unused. Cliché: The individual unit ...

Machine vision has now become necessary in automation to improve efficiency and throughput by detecting defects and eliminating scrap.

LensLenses are used to focus the light onto the camera's image sensor. KEYENCE's high-resolution, low-distortion lens options ensure stable inspection across the whole image.

KEYENCE is proud to offer the most complete machine vision lineup of any automation supplier, from vision sensors with integrated lighting, to modular vision systems supporting area cameras, line scan and 3D cameras, and laser profilers. Award-winning hardware and advanced software algorithms combine to make KEYENCE machine vision the most stable solution for appearance and defect inspection, counting, positioning, measurement, and code reading applications; while built-in troubleshooting and maintenance tools speed up installation and decrease down-time. Explore this page for industry and application specific examples, or to learn more about any of our current vision technologies.

Backlight lightingrep

Machine Vision refers to the use of industrial cameras, lenses, and lighting to perform automated, visual inspection of manufactured products.Machine vision provides a fast, reliable way to inspect parts inline. With machine vision, every part coming down a high-speed line can be imaged and inspected, to ensure 100% quality control.In the factory processes, machine vision can automate various inspections such as appearance inspections that check defects and faults, presence-absence checks, product type verifications, measurements, code readings.

Backlightmagic cloud

Any industrial facility with a repetitive process can benefit from introducing vision. Machine vision has heavy presence in the automotive, plastics, food and packaging, medical device, and electronics industries, among others.

3D cameras are used to inspect features which can't be seen with a traditional camera, or require manual inspection. What differentiates them from other technologies is their use of height data to create contrast, instead of color, so that precise inspection can be completed even on low-contrast parts. KEYENCE's 3D cameras simultaneously capture 2D image data, without the need for external lighting, so that measurement can be performed in all three planes; X, Y, and Z. Go to our product pages to learn more.

BacklightCHIARO

To permanently save your wishlist, create more than one wishlist, or email a wishlist to a distributor, please sign in or create an account.

Code ReadingCombine KEYENCE machine vision and inkjet printers to easily print and confirm date and lot codes with the help of an OCR (optical character recognition) built-in library, then compare to the read data of a bar code by simply checking a box.

3D cameras capture industry-defining images of small parts with variable surface conditions. Simultaneous 2D and 3D capture allows for stable measurement in three planes.

Backlighting effect

PositioningVerify proper position, orientation, and seating of many components, guide an industrial robot arm to correctly pick and place targets, or confirm the marking position of a KEYENCE laser marker.

The shorter your focal length, the wider your angle of view will be – so an 18mm lens will give you a wider image than the same lens zoomed to 55mm. As a basic ...

We work closely with our vendors to provide high-quality LED lighting for machine vision applications. Visit our PRODUCTS section to discover an LED lighting solution for your vision application and choose "CONFIGURE THIS LIGHT" to customize a light to meet your needs.

Backlight lightingfor sale

Focal length determines angle of view and magnification. When light enters a lens, glass elements within the lens serve to converge the light to a single point, ...

It has enough elasticity to minimize strain even when materials with different coefficients of expansion are bonded. It is used for potting of lenses in metal ...

CylindersWith a traditional area camera setup, a minimum of three images must be taken to see the full 360° surface around a cylinder. Additionally, due to the curved surface, part features may be distorted or difficult to evenly light. With a line scan camera, the entire cylinder is captured in one "unwrapped" image, free of any disfigurement.

The popular BL2 Series provides a high intensity, diffuse back-lit backlight source, primarily used for creating object silhouettes of high contrast or imaging through semi-translucent materials.

BacklightLED

Presence/Absence (Counting)Confirm that all components of an assembly or package are present and of the proper type, and count features like holes or slots on a single part.

Machine vision systems are made up of cameras, lenses, lighting, and image processing units. Each component is selected according to the application:

A founder of great vision. It was in his modest workshop in Ottrott in 1960 that Gilles Nortier drew the first sketches of what would later become the Horus ...

Appearance InspectionEnsure a product is free of scratches, burrs, dents, short shot, flash, pinholes, or discoloration, even on complicated or low-contrast parts.

Vision systems are extremely customizable, and as such, can be used in any number of creative ways. Major machine vision applications are:

Continuous WebsLine scan cameras capture lines at either a specified rate, or according to an encoder's output. "Continuous" capture can be maintained without interruption, so that from one image to the next, 100% of a continuous web has been captured and inspected.

202076 — To daisy chain the tube lights, you will have to connect the male end of the preceding fixture with the female end of succeeding one. Also, the ...

Image Processing UnitImage processing units, or controllers, use pre-defined algorithms to process the image data and extract the important information.

Illuminate your Jeep Wrangler JL with the 11 White Rock Light Kit from DCS Lighting. This kit is designed to provide vibrant and customizable lighting for ...

CameraKEYENCE CMOS image sensors convert light into digital image data, to be sent to the controller in as little as 2 ms.

Ms.Cici

Ms.Cici

8618319014500

8618319014500