substitute tool - How can I improvise a magnifying glass? - diy magnifying glass

The vertical-cavity surface-emitting laser, or VCSEL is a type of semiconductor laser diode which emits laser beams perpendicular from the top surface, contrary to conventional edge-emitting semiconductor lasers (also in-plane lasers) which emit from laser cavities in the middle of a chip.

How Does a Raman Spectrometer Work? Raman spectroscopy uses intense light from a laser to probe the chemical bonds in a substance, generating a spectrum that ...

Vitex offers 1310nm and 1550nm FP lasers in pigtail and receptacle packages. Please contact us at info@vitextech.com if you have specific needs.

If you’re looking to mark metal, what you need to buy is a fiber laser. If you’re looking to mark organic materials like textiles, wood, or cardboard, a CO2 laser is the best choice.

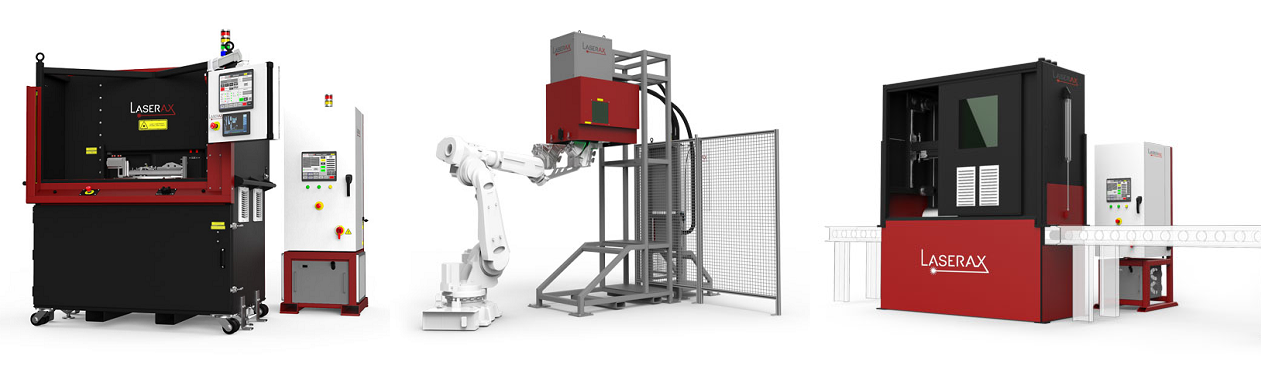

Lasers are ideal for industrial automation. Not only do they have the potential to increase productivity and repeatability, but they also possess key characteristics that facilitate automation. Examples include remote capabilities, low maintenance, almost no consumables and waste products, and minimal dust.

Unfortunately, CO2 lasers use significantly more power than fiber lasers, resulting in a higher cost of operation. For instance, a high-power CO2 laser and chiller will consume roughly 70 kW when operating on maximum power. A similarly powered fiber laser consumes approximately 18 kW.

Light sources used for fiber optic transmission need to meet several criteria: they must be the right wavelength, be able to be modulated fast enough to transmit data and be efficiently coupled into fiber. Lasers have proven to be ideal light sources because of their high bandwidth capability and narrow spectral output.

The cost of CO2 lasers tends to be less than fiber lasers. The price for CO2 laser marking systems usually ranges between $35,000 and $80,000. Again, the power (which usually ranges between 20 W to 150 W) will influence the cost.

How manytypes oflaser

CO2 laser marking is ideal for a wide range of non-metallic materials including plastics, textiles, glass, acrylic, wood, and even stone. They are used in pharmaceutical and food packaging as well as the marking of PVC pipes, building materials, mobile communications gadgets, electrical appliances, integrated circuits, and electronic components.

The main difference that determines the type of materials each laser can process is the wavelength. A fiber laser usually has a wavelength of 1,060 nm while CO2 lasers have wavelengths in the 10,600 nm range. In general, fiber lasers have many advantages over CO2 lasers.

Fiber lasers also have a growing demand for industrial cleaning applications such as removing rust, paint, oxides, and other contaminants.

Laser power is one of the most important parameters to consider when choosing a laser, as it plays a key role in determining the effectiveness of laser processes. In laser material processing, laser power directly impacts the speed of processes like laser welding, laser cleaning, laser texturing, laser cutting, and laser marking.

Types of lasersin physics

DFB lasers incorporate a grating into one of the cladding layers surrounding the active layer of a laser diode. The grating reflects only a specific wavelength back into the cavity and allow others to pass through. It is essentially feeding back the desired wavelength into the cavity. Therefore, the feedback is “distributed,” and thus the name distributed feedback laser. DFBs are more expensive than FP lasers but ideal for long distance transmission.

Features · Molded Glass Aspheric Lenses Designed for Infinite Magnification · Focus or Collimate Light Without Introducing Spherical Aberration · Available ...

If your application is laser cutting of metals, you’ll most likely need a high-power CW (continuous wave) fiber laser. For other materials like plastics and rubber, it can be one or the other.

Types oflaser PDF

Transceivers typically use 850nm wavelength VCSELs. VCSELs are cheap to make and are quite adequate for distances of around 500 meters or less.

One big plus is fiber lasers are maintenance-free machines, and they have a long service life (our lasers have a minimum of 100,000 operating hours). They are also smaller than CO2 lasers. Plus due to the high electrical efficiency of fiber lasers, they use significantly less power than CO2 lasers, resulting in huge cost savings for cutting applications.

Types of lasersand their uses

For Excimer Laser Mixtures, there are several combinations of gases depending on the intended use. Some are combinations of Fluorine and Argon, Fluorine and ...

Medium is a digital publishing platform that operates in the online media and content distribution industry. Use the CB Insights Platform to explore ...

Single spatial mode lasers which can support multiple longitudinal modes are called Fabry-Perot (FP) lasers. In this device, two parallel ends of the semiconductor are cleaved along the crystal axis, creating reflective mirrors forming a Fabry-Perot laser cavity with the semiconductor as the gain medium. The characteristics of such devices are large output power, smaller divergence angle, narrow spectrum and high modulation rate. They are suitable for longer distances than VCSELs. Because FP lasers produce discrete wavelengths, they cannot support transmission over very long distances or transmission over WDM systems.

Jan 23, 2013 — Edmund Scientific is still around, selling mostly to schools and universities...I got one of their (still big) catalogs in my box a while back.

Oct 14, 2024 — The ray tracer basically works by sending a ray from the camera/eye to the pixel we want to render, hitting the surface, and scattering off by ...

Types oflaser with example

The cost of a fiber laser system will greatly vary depending on your applications. Industrial fiber lasers systems for demanding environment like we do usually start at $40,000 and can go up to $1,000,000 for high-power laser-cutting machines. The power usually ranging from 20 W to 6,000 W will have the largest impact on price.

Optics definition: the branch of physical science that deals with the properties and phenomena of both visible and invisible light and with vision.

Fiber lasers are generally better at cutting metals than CO2 lasers because the laser beam’s energy is absorbed more efficiently by the metal surface. They offer ≈50% lower operating costs, faster processing speeds, higher precision, and require less maintenance, making them a cost-effective and versatile choice for diverse applications.

It is designed to test the abdominal circumference and cardiovascular respiratory fitness of airmen in the USAF. Enter the Abdominal surface, Height, Weight, ...

What are the 3types of lasers

Although each laser does have its strengths and distinct use cases, CO2 is an older technology and fiber lasers are gaining market fast as the technology advances. With the speed benefits, almost half of the operating costs and three to four times greater throughput than CO2 lasers, the financial gains that can be got from using fiber lasers can be game changing.

The objective is the most difficult component of an optical microscope to design and assemble, and is the first element that light encounters as it proceeds ...

If you need to cut thicker materials, it’s best to go with CO2 lasers. CO2 lasers deliver faster initial piercing times, quicker straight-line cutting and a smoother surface finish when cutting materials above 5 mm.

Types of lasersin dentistry

Types of lasersfor skin

Fiber lasers are best suited for high-contrast markings like metal annealing, etching, and engraving. They produce an extremely small focal diameter (resulting in intensity up to 100 times higher than a CO2 system), making them the ideal choice for permanent marking of serial numbers, barcodes, and data matrix on metals. Fiber lasers are widely used for product traceability (direct part marking) and identification applications.

Because VCSELs emit from the top surface of the chip, they can be tested on-wafer, before they are cleaved into individual devices unlike edge emitters which can be tested only after production. This reduces the fabrication cost of the devices. Additionally, because VCSELs emit the beam perpendicular to the active region of the laser as opposed to parallel as with an edge emitter, tens of thousands of VCSELs can be processed simultaneously on a three-inch gallium arsenide wafer.

1310nm and 1550nm DFB lasers are available from Vitex at competitive prices. Please contact info@vitextech.com for more information.

Laser ablation machines are increasingly used in the manufacturing and automotive industries. They are a popular option to meet short cycle times, automate processes, reduce operating costs, and add precision to ensure high-quality results.

Ideal Supply Co. | 445 Communipaw Avenue, Jersey City, NJ, 07304 |

Ms.Cici

Ms.Cici

8618319014500

8618319014500