Strobe lights, vertigo, and epilepsy - strobing lights

Hi everyone! In the following article, we are going to review the Creality PrintMill CR-30 — a conveyor belt 3D printer that can print objects of virtually any length. Read on to learn more about the device.

cr-30 3d printer

Reflection is the phenomenon where waves bounce off a surface, reversing their direction. This behaviour is common in light and sound waves and can be observed in everyday life.

Creality has developed an exclusive slicing software specifically for this type of machine — CrealityBelt. Printing of one object of any length is not fundamentally different from a usual one, and serial printing of many objects is set up in a slicer program.

The PrintMill CR-30 platform belt is made from a rough material claimed to be wear-resistant nylon, which holds prints well during printing. When they reach the end of the belt and the roller, they are easily removed. The belt itself is replaceable.

When a wave passes from one medium to another with a different refractive index, its speed changes. This change in speed leads to refraction, or the bending of the wave. But what happens to the frequency and wavelength of the wave during this process?

cr-30 slicer

The texture of the belt leaves a trace on the bottom surface of the print, which may not be suitable for some models and applications. In this case, it is better to set a couple of additional layers in this area of the model, which can then be mechanically sanded or dissolved.

Constructive interference occurs when waves meet in phase, their amplitudes add together, creating a wave with a larger amplitude.

Creality promises an "ultra-quiet motherboard" with a "silent chipset". Presumably, the printer will use one of the newest Creality 4.2.x 32-bit cards. with TMC2208 stepper motor drivers.

CR 305e

Where `n_1` and `n_2` are the refractive indices of the two media, and `\theta_1` and `\theta_2` are the angles of incidence and refraction, respectively.

The wavelength of the wave changes in proportion to the speed of the wave as it enters a new medium. If the wave slows down (as it does when moving from a medium with a lower refractive index to one with a higher refractive index), the wavelength decreases. Conversely, if the wave speeds up (when moving from a higher to a lower refractive index), the wavelength increases.

The location of the geometric axes in the PrintMill CR-30 differs from the traditional one. Here, Z is not the vertical to the build plate, as is usual in FDM printers — it is the length obtained with the conveyor belt. X is the axis along the width of the platform located at an angle of 45°, and Y is the axis of movement of the print head up and down.

Destructive interference occurs when waves meet out of phase, their amplitudes cancel out, creating a wave with a smaller or even zero amplitude.

Refraction changes the speed of a wave as it passes from one medium into another, but it does so without altering the wave's frequency.

cr-30 belt

An additional roller platform is provided for printing long objects and preventing them from sticking in the print area.

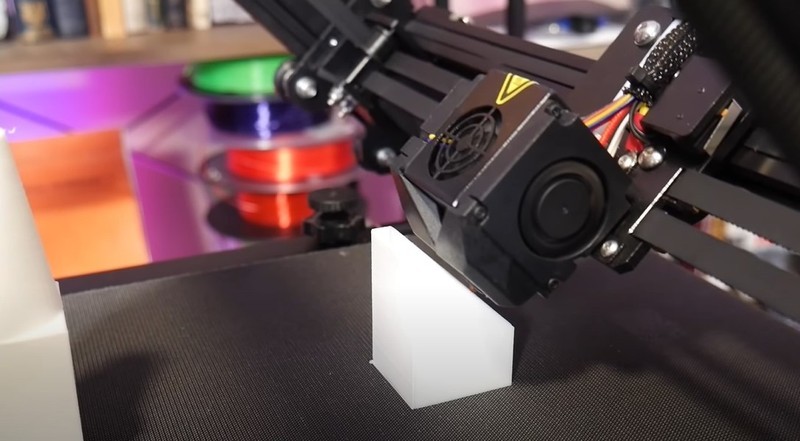

The PrintMill CR-30 features a hot end with two cooling fans for accurate printing and fine detail. A 0.4 mm nozzle is supplied as standard.

CR-30 extruder

The device can be applied in the creation of toys and souvenirs, advertising structures and interior decor, theater and cosplay props, unloaded constructional elements and prototypes of products for industry.

The Creality PrintMill CR-30 is not the easiest 3D printer to use, but its capabilities can be employed for full-scale serial production and printing models of a size that is unreachable to the vast majority of other desktop FFF and FDM printers.

Calibration of the "platform", that is, the conveyor belt, can be done on site, but it will be quite some time before it's needed — the manufacturer states that the printers are carefully calibrated at the factory.

Vice versa, if the refractive index of the second medium is smaller than the first medium, the wave would bend away from the normal as it travels through the medium.

creality cr-30 review

When waves pass through a narrow slit, they spread out in a pattern that can be described using the wavelength and the size of the opening. As the size of the opening becomes smaller, the degree of diffraction increases.

The frequency of a wave is determined by the source of the wave and remains constant as the wave passes through different media. Since the frequency doesn't change, any alteration in speed must be compensated for by a corresponding change in wavelength.

creality cr-30 alternative

Wave superposition is the phenomenon where two or more waves combine to form a resultant wave. The resultant wave's amplitude at any point is the sum of the amplitudes of the individual waves at that point.

cr-30 print speed

Snell's Law provides a mathematical way to predict the angle of refraction based on the medium's refractive index. It's expressed as:

Wave behaviour is a crucial aspect of Year 11 HSC Physics. It encompasses several phenomena, including reflection, refraction, diffraction, and wave superposition. Understanding these principles can give us insights into everything from the way light interacts with materials to the propagation of sound waves.

The angle of incidence (the angle between the incoming wave and the normal of the surface) is equal to the angle of reflection (the angle between the reflected wave and the normal). The normal is a perpendicular line drawn from the surface.

With the width of the belt being 23 cm — of which 20 are those for printing — and the 17 cm height of the build area, we get the ultimate build volume of 170 x 200 x ∞.

The specific design of the printer mechanics dictates that the layers of a model are applied at an angle of 45° to the surface of the belt. For some models, it is rather an advantage. Some changes in the approach to project design and the position of the part in the print area may also be required.

From an economic point of view, serial 3D printing on this device is quite justified as long as relatively small batches of products are concerned.

If the refractive index of the second medium is greater than the first medium, then the angle of refraction would be smaller than the angle of incidence. This means the wave would bend towards the normal as it travels through the medium.

The roller platform also helps transport smaller models when printed in series — they go from the belt to the platform and roll along it into a bin. Thus, it enables really uninterrupted printing limited only by the amount of filament, which allows the serial production of hundreds and thousands of parts.

Ms.Cici

Ms.Cici

8618319014500

8618319014500