Semi-Spherical Hole - General Woodworking Talk - half spherical

DLCcoatingnear me

Tribo 500 series was specifically developed for the fast paced multiple coating job or in-house coating center where speed of process change over is key to higher utilizations. With up to 6 source positions high value small batch complex multi layer or combinatorial process are simplified. The Tribo series is flexible and highly configurable and upgradeable to cover the full range of standard tribological al coatings.

Diamond-likecarbon coatingService

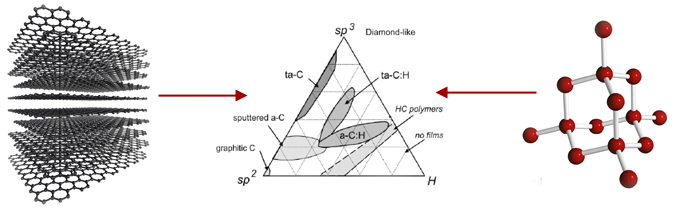

DLC coatings are also commonly applied onto various medical and dental instruments and implants to provide a dark black, anti-reflective and bio-compatible surface with enhanced tribological protection properties.Mustang’s DLC system portfolio can also be routinely used for a wide range of decorative, optical, electrical, defense, sporting and chemical protection applications.Systems for metal containing (typically Ti or W containing) and a range of metal-free DLC variants plus bond layers are available which also have the ability to control the sp2:sp3 (the graphite : diamond phase composition) of the film, the micro-hardness, friction coefficient, microstructure and can be additionally doped for selected electrical, mechanical and thermal applications.

Frequency multiplying is a technique used to produce a wavelength that is one half (or one third or one quarter) of the fundamental wavelength of a laser. Using this technique the 1.06µm Nd:YAG beam can be produced 'frequency doubled' at 0.53µm, or with a wavelength of 0.266µm if 'frequency quadrupled', for example. The potential benefits of this are that the shorter wavelength will often be absorbed better by the material being processed and can also be focussed to a smaller spot size, thereby increasing available power density. These 'frequency multiplied' advantages however come at a cost of quite significantly lower average power output than at the fundamental frequency of the laser concerned, due to the inefficiency of the process. Commercial frequency doubling relies on non-linear crystals. As a laser beam passes through the crystal, non-linear interactions between the beam and the material (e.g. lithium borate with Nd:YAG), generate electromagnetic waves at twice the laser frequency. Generation of third and fourth harmonics using non-linear crystals is usually a multistep process. Generating a second harmonic, then mixing it with the fundamental wavelength in another non-linear crystal, so the frequencies combine, produces the third harmonic. To produce the fourth harmonic, the output of a second harmonic generator is passed through a second frequency doubler. Clearly generation of frequency tripled and quadrupled laser light is highly inefficient.

DLCcoatingprice

Tribo 960 series is a large format production tool designed specifically for decorative and functional tribological c coatings on large 3D parts such as door hardware, plumbing fixtures and firearms . Up to 6 source positions enable very high deposition rates reducing cycle times and increasing annual system capacity. Tribo series is flexible and highly configurable and upgradeable to cover the full range of standard tribological al coatings.

Amorphous Diamond-like-Carbon coatings, typically deposited at substrate temperature <250°C, possess a unique combination of physical, mechanical, chemical and optical properties. The percentage of bonded sp2 & sp3 carbon atoms, metal content and hydrogen content of the films can be manipulated by both the deposition chemistry & methodology (sputter, evaporation, PACVD etc). Mustang Vacuum Systems offers a series of deposition chambers and chamber sizes to deposit a range of low friction, highly wear resistant diamond-like-carbon (DLC) and dry lubricant coatings, utilizing precise recipe control and process monitoring feedback to ensure consistent high quality results.

Diamond like carbon coatingreview

Tribo 500 series was specifically developed for the fast paced multiple coating job or in-house coating center where speed of process change over is key to higher utilizations. With up to 6 source positions high value small batch complex multi layer or combinatorial process are simplified. The Tribo series is flexible and highly configurable and upgradeable to cover the full range of standard tribological al coatings.

Diamond-like-Carbon coatings are used in demanding automotive, non-ferrous material machining and industrial engineering environments where component surfaces are subjected to high contact pressure, intermittent lubrication or dry sliding and rolling environments where severe abrasive and adhesive wear conditions exist. DLC coatings are also commonly applied onto various medical and dental instruments and implants to provide a dark black, anti-reflective and bio-compatible surface with enhanced tribological protection properties.

Tribo 960 series is a large format production tool designed specifically for decorative and functional tribological c coatings on large 3D parts such as door hardware, plumbing fixtures and firearms . Up to 6 source positions enable very high deposition rates reducing cycle times and increasing annual system capacity. Tribo series is flexible and highly configurable and upgradeable to cover the full range of standard tribological al coatings.

Ms.Cici

Ms.Cici

8618319014500

8618319014500