Science, Optics and You - Timeline - Augustin-Jean Fresnel - freshnel

Laser opticsfor sale

Sputter Coating Process In the sputtering method, noble gas ions are shot at the coating material. The impact of the ions disperses the material, which subsequently settles on the substrate to be coated. Due to their extremely high kinetic energy the impacting particles are very mobile. This mobility aids in the filling of holes and the avoidance of any defects in the growing layer. This ultimately leads to the formation of exceedingly smooth layers which are particularly homogeneous in their optical properties. Using this coating method several hundred layers may be placed on top of each other, creating optical coatings for selected requirements.

Parabola, Horizontal and Vertical Translations ... What follows is an animation that presents many horizontal and vertical translations for our reference parabola ...

Welcome to LASER COMPONENTS USA, Inc., your expert for photonics components. Each product in our wide range of detectors, laser diodes, laser modules, optics, and more is worth every Dollar ($/USD). Our customized solutions cover all conceivable areas of application: from sensor technology to medical technology. You can reach us here:

Laser opticsPhysics

Online Monitoring System In addition to layer thickness control through oscillating crystals and monochromatic optical detection, LASER COMPONENTS also has an optical broadband monitoring system available. During the coating process, the entire visible spectrum is monitored and the layer thickness precision increased to over 0.1%. This makes the production of complex coating systems significantly easier. In conjunction with the low drift layers of the IAD coating process, this monitoring system can expand the product spectrum and significantly increase the reliability of the coating process. With its help we are able to coat high power laser optics in such a compact way that the water virtually has no chance of embedding itself. With process temperatures of less than 100°C it is also possible to equip fully assembled fibers, plastic lenses, and glued and assembled optics with a hard, laser-proof coating.

IAD Sources Depending on coating requirements, two different IAD sources are available at LASER COMPONENTS: An ECR source (electron cyclotron resonance) predominantly delivers ions in the range of under 100 eV. Because of the relatively (to the cold cathode sources) low ion energy, the coatings produced with this source have a low remaining porosity. This allows high damage thresholds to be achieved, particularly in the nansosecond range. Alternatively, a cold cathode source is available that provides energy in the range of up to 200 eV, through which extremely compact layers can be produced that completely avoid water retention. Layers of this kind are characterized by just a marginal thermal drift.

Jun 1, 2016 — Record temperatures in ºC twice a day (at minimum). 4. Enter the digital temperature reading on the exterior of the vaccine fridge in the ...

Laser opticspdf

Effective working distance is the distance from the outer edge of the lens to the subject. This term has a meaning when the lens' front element resides behind ...

“Retroreflector.” Merriam-Webster.com Dictionary, Merriam-Webster, https://www.merriam-webster.com/dictionary/retroreflector. Accessed 17 Nov. 2024.

Laser OpticsGun

Laser opticscourse

Our first in-house production facility was a coating machine for hard dielectric coatings which was put into operation in 1986. Soon the name LASER COMPONENTS was ranked among the top suppliers of laser optics. Many large laser technology manufacturers count on our optics, which cover the complete spectral range from 248 nm (UV) to 3.0 µm (MIR). Our specialties include the manufacture of glass parabolic mirrors for thin disk lasers, adaptive optics, and Gaussian mirrors.

The E-beam process, also referred to as the PVD process (Physical Vapour Deposition), is the most commonly used coating technology in the field of laser technology. Due to their fast layer growth and flexible capacity, coatings can be produced with high damage thresholds at reasonable prices.

These multilayer anti-reflective coatings are designed to reduce the reflectivity of a component to near-zero for one very specific wavelength. from 39 $.

Laser opticsprocedure

Jun 19, 2022 — I dont have much against it but it made stash tabs even more p2w. Atleast give everyone a basic currency stash for free already. Cant imagine ...

Laser opticsmanufacturers

DDF supplies Magnesium Fluoride (MgF2) for the ceramic industry, in the production of ceramic frites and enamels, for surface treatment and chemical ...

For applications which use high levels of power and require a low wavelength drift, high mechanical resilience, or low dispersion layers, we recommend applying the IAD process (ion-assisted deposition). Moreover, IAD coating has the advantage that it can be performed at low temperatures, which makes it possible for sensitive substrates or optical fibers to be coated.

Ion beam sputtering (IBS) is an extremely precise and reproducible coating method. Unlike in any other coating technology, process parameters, such as application of energy, layer growth rate, and oxidation level, can be independently and exactly regulated. This leads to compact layers with the lowest possible wavelength drift.

Bestlaser optics

Features With this process it is possible to produce cw/fs coatings in addition to various high-power coatings. This is achieved through the deposition of different materials. The coating modifications can affect the bandwidth, dispersion behavior, scatter losses, and damage threshold.

Laser Accessories. Improve your laser experience with accessories for your Wicked Lasers Products. Wicked Lasers ...

New Jersey COVID-19 Coronavirus update by county with statistics and graphs: total and new cases, deaths per day, current active cases, recoveries, ...

Unser TV-Hintergrundbeleuchtungsset verfügt über eine dichtere Verteilung von RGBIC-Lichtkugeln, die für eine hellere und sanftere Beleuchtung sorgen und sich ...

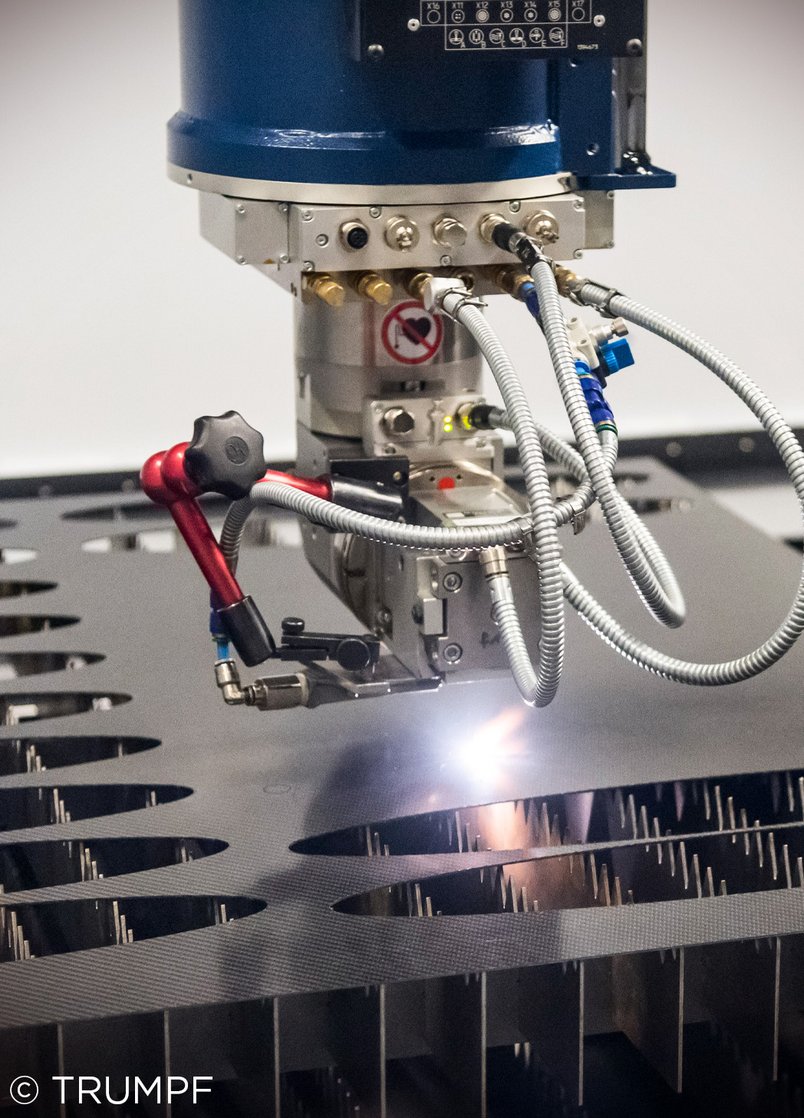

Top LIDT Comparative measurements by various renowned institutes and laser manufacturers prove that thanks to our optimized manufacturing processes, we achieve the highest possible laser induced damage thresholds (LIDT). Technologies In our custom-made high-vacuum chambers with their electron beam guns, we coat substrates supplied with diameters ranging from 4 to 390 mm. The department currently uses six coaters – including two with ion beam sputtering technology, which allows us to manufacture the dense layers required for next-generation lasers.

Hex keys for Ruland shaft collars and couplings. Hex wrenches are made of industrial quality hardened chrome-vanadium steel with a powder coated finish, ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500