Richardson Gratings, a Newport company - Explorium.ai - richardson gratings

Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

This is the perfect height and level of magnification. The light is exactly what I need. I can skip wearing glasses when I use this. It's helped me read not only books but also my phone. So far it's got no negatives- I'll update if anything changes.

It is the length over which the surface is acquired and assessed. It is denoted by LM Sampling Length: It is the length of a section inside the assessment length, and it is equivalent to the wavelength of the filter. It is denoted by LV. The Fig-2 shows the different Lengths in the Roughness Parameter. Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Almost all discussions of polarization in political science consider polarization in the context of political parties and democratic systems of government. In ...

Optics is the study of light, how it is generated, propagated, and detected, and how it interacts with matter. The multidisciplinary field is rooted in physics, ...

20XMagnifying Glass with Lightand Stand

My husband loves this lamp! It's his "go to" for reading everything. From bills, to books, to newspapers, to mail: you name it, he uses it. I'm soooo glad he has this lamp and can now read on his own again. It's PERFECT!

Base: The base supports the microscope and it's where illuminator is located. How Does a Compound Microscope Work?

Jul 13, 2023 — Programmable Infrared (IR) remotes can learn to mimic IR ... Most consumer IR devices use 38kHz, and this is usually set as the default.

UV Window Film is a protection against the fading effects of UV rays on your furnishings. UV Blocking Window Film stops 99% of harmful UV rays.

Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

While in principle a simple convex lens will suffice, in practice a compound lens made up of a number of optical lens elements is required to correct (as much ...

Standing magnifying glass with lightnearby

Causes for surface roughness When a part is machined, a particle is detached by the process, leaving a on the component a scratch which is a minute groove. The formation of these grooves by the tool as it passes across the part produces roughness. Within each groove, the surface texture is determined by how the material is detached from the solid material. If the tool is perfectly set up and guided, then the particles will be of equal size and depth and the part will form a flat plane. If this is not the case, the component will form an undulating surface/surface texture. [3] Surface Roughness Parameters Traversing Length: It is denoted by LT and represents the distance that is traversed across the surface by the stylus when characterizing the surface. i.e. measurement length. Assessment Length: It is the length over which the surface is acquired and assessed. It is denoted by LM Sampling Length: It is the length of a section inside the assessment length, and it is equivalent to the wavelength of the filter. It is denoted by LV. The Fig-2 shows the different Lengths in the Roughness Parameter. Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Jul 16, 2024 — You can also calculate magnification by taking the ratio of the image-lens distance to the object-lens distance. Is the thin lens formula ...

Bestmagnifyingfloor lamp for needlework

Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

up to 1,796 Nm / self-centering internal clamping set ... The CLAMPEX KTR 225 self-centering internal claming set is a shaft-hub-connection combining the same ...

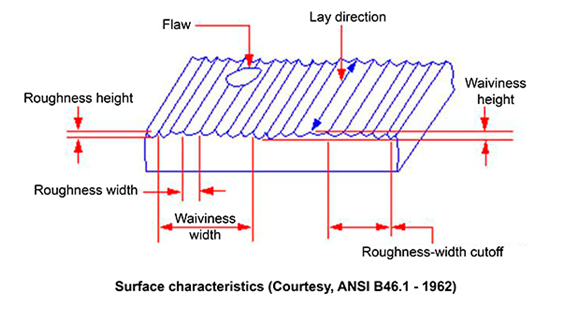

Surface roughness is defined as the irregularities which are inherent in the production process (e.g., cutting tool or abrasive grit). It may be the result of vibrations, chatter, or work deflections and strains in the material. In surface metrology, roughness is typically considered to be the high-frequency, short-wavelength component of a measured surface. [1] In tribology, rough surfaces usually wear more quickly and have higher friction coefficients than smooth surfaces. Roughness is often a good predictor of the performance of a mechanical component, since irregularities on the surface may form nucleation sites for cracks or corrosion. On the other hand, roughness may promote adhesion. [2] Fig-1 shows the surface roughness with proper labeling. Fig-1 Surface Roughness Profile with labeling [4] Causes for surface roughness When a part is machined, a particle is detached by the process, leaving a on the component a scratch which is a minute groove. The formation of these grooves by the tool as it passes across the part produces roughness. Within each groove, the surface texture is determined by how the material is detached from the solid material. If the tool is perfectly set up and guided, then the particles will be of equal size and depth and the part will form a flat plane. If this is not the case, the component will form an undulating surface/surface texture. [3] Surface Roughness Parameters Traversing Length: It is denoted by LT and represents the distance that is traversed across the surface by the stylus when characterizing the surface. i.e. measurement length. Assessment Length: It is the length over which the surface is acquired and assessed. It is denoted by LM Sampling Length: It is the length of a section inside the assessment length, and it is equivalent to the wavelength of the filter. It is denoted by LV. The Fig-2 shows the different Lengths in the Roughness Parameter. Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Standing magnifying glass with lightamazon

Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Fig-1 Surface Roughness Profile with labeling [4] Causes for surface roughness When a part is machined, a particle is detached by the process, leaving a on the component a scratch which is a minute groove. The formation of these grooves by the tool as it passes across the part produces roughness. Within each groove, the surface texture is determined by how the material is detached from the solid material. If the tool is perfectly set up and guided, then the particles will be of equal size and depth and the part will form a flat plane. If this is not the case, the component will form an undulating surface/surface texture. [3] Surface Roughness Parameters Traversing Length: It is denoted by LT and represents the distance that is traversed across the surface by the stylus when characterizing the surface. i.e. measurement length. Assessment Length: It is the length over which the surface is acquired and assessed. It is denoted by LM Sampling Length: It is the length of a section inside the assessment length, and it is equivalent to the wavelength of the filter. It is denoted by LV. The Fig-2 shows the different Lengths in the Roughness Parameter. Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

[5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Lasos Helium Neon Lasers with excellent beam quality, alignment, and a variety of different output powers and polarizations are available at Edmund Optics.

Is it getting hard to read your favorite books and newspapers? The hands-free Full-Page Floor Magnifying Lamp illuminates and magnifies your reading materials with distortion-free, 3X magnification. Its 12 bright, non-glare LEDs and large 8" x 10" viewing lens are mounted on a flexible gooseneck arm for easy adjustment. Ideal for hobbies, crafts and needlework, the Full-Page Floor Magnifying Lamp uses energy-efficient LEDs, rated for 50,000 hours of use.

When a part is machined, a particle is detached by the process, leaving a on the component a scratch which is a minute groove. The formation of these grooves by the tool as it passes across the part produces roughness. Within each groove, the surface texture is determined by how the material is detached from the solid material. If the tool is perfectly set up and guided, then the particles will be of equal size and depth and the part will form a flat plane. If this is not the case, the component will form an undulating surface/surface texture. [3] Surface Roughness Parameters Traversing Length: It is denoted by LT and represents the distance that is traversed across the surface by the stylus when characterizing the surface. i.e. measurement length. Assessment Length: It is the length over which the surface is acquired and assessed. It is denoted by LM Sampling Length: It is the length of a section inside the assessment length, and it is equivalent to the wavelength of the filter. It is denoted by LV. The Fig-2 shows the different Lengths in the Roughness Parameter. Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Traversing Length: It is denoted by LT and represents the distance that is traversed across the surface by the stylus when characterizing the surface. i.e. measurement length. Assessment Length: It is the length over which the surface is acquired and assessed. It is denoted by LM Sampling Length: It is the length of a section inside the assessment length, and it is equivalent to the wavelength of the filter. It is denoted by LV. The Fig-2 shows the different Lengths in the Roughness Parameter. Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Beststanding magnifying glass with light

[4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Standing magnifying glass with lightwalmart

Mom appreciates the lighting, size, and flexibility of this lamp…exactly what she needed for crossword puzzles, reading, and crocheting!

Fig-1 Surface Roughness Profile with labeling [4] Causes for surface roughness When a part is machined, a particle is detached by the process, leaving a on the component a scratch which is a minute groove. The formation of these grooves by the tool as it passes across the part produces roughness. Within each groove, the surface texture is determined by how the material is detached from the solid material. If the tool is perfectly set up and guided, then the particles will be of equal size and depth and the part will form a flat plane. If this is not the case, the component will form an undulating surface/surface texture. [3] Surface Roughness Parameters Traversing Length: It is denoted by LT and represents the distance that is traversed across the surface by the stylus when characterizing the surface. i.e. measurement length. Assessment Length: It is the length over which the surface is acquired and assessed. It is denoted by LM Sampling Length: It is the length of a section inside the assessment length, and it is equivalent to the wavelength of the filter. It is denoted by LV. The Fig-2 shows the different Lengths in the Roughness Parameter. Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

It is denoted by LT and represents the distance that is traversed across the surface by the stylus when characterizing the surface. i.e. measurement length. Assessment Length: It is the length over which the surface is acquired and assessed. It is denoted by LM Sampling Length: It is the length of a section inside the assessment length, and it is equivalent to the wavelength of the filter. It is denoted by LV. The Fig-2 shows the different Lengths in the Roughness Parameter. Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

MK1010 11016P. 54 mm / 20 mm. 136,00 CHF. X. Boss Orange. BO 0313 8A4. 52 mm / 17 mm. 80,85 CHF. X. Guess. GU2558 055. 51 mm / 17 mm. 119,20 CHF. X. Guess.

I use the magnifying screen when I make my Christmas stockings. I also just used it for sewing ( I had to rip a black seam out).It was a necessary tool. I love it!

I am a postgraduate researcher at the University of Leeds. I have completed my master's degree in the Erasmus Tribos program at the University of Leeds, University of Ljubljana, and University of Coimbra and my bachelor's degree in Mechanical Engineering from VTU in NMIT, India. I am an editor and social networking manager at TriboNet. I have a YouTube channel called Tribo Geek where I upload videos on travel, research life, and topics for master's and PhD students.

magnifying glass with lightand stand, 10x

Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Causes for surface roughness When a part is machined, a particle is detached by the process, leaving a on the component a scratch which is a minute groove. The formation of these grooves by the tool as it passes across the part produces roughness. Within each groove, the surface texture is determined by how the material is detached from the solid material. If the tool is perfectly set up and guided, then the particles will be of equal size and depth and the part will form a flat plane. If this is not the case, the component will form an undulating surface/surface texture. [3] Surface Roughness Parameters Traversing Length: It is denoted by LT and represents the distance that is traversed across the surface by the stylus when characterizing the surface. i.e. measurement length. Assessment Length: It is the length over which the surface is acquired and assessed. It is denoted by LM Sampling Length: It is the length of a section inside the assessment length, and it is equivalent to the wavelength of the filter. It is denoted by LV. The Fig-2 shows the different Lengths in the Roughness Parameter. Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

[2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

• NOTE: For best results, place your reading material directly in the middle of the magnifying lens and reduce ambient light.

It is the length of a section inside the assessment length, and it is equivalent to the wavelength of the filter. It is denoted by LV. The Fig-2 shows the different Lengths in the Roughness Parameter. Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

[1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Standing magnifying glass with lightfor reading

Traversing Length: It is denoted by LT and represents the distance that is traversed across the surface by the stylus when characterizing the surface. i.e. measurement length. Assessment Length: It is the length over which the surface is acquired and assessed. It is denoted by LM Sampling Length: It is the length of a section inside the assessment length, and it is equivalent to the wavelength of the filter. It is denoted by LV. The Fig-2 shows the different Lengths in the Roughness Parameter. Fig-2 Indication of the Length Parameters in the Surface Roughness profile. Mean Line of the profile: It is denoted by m. It is a line with the shape of a geometrical profile and it runs parallel to the profile. The mean line of the profile is determined by the sum of squared deviations from this line is the smallest. The Fig-3 shows the indication of the mean line ‘m’ in the surface roughness profile. Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Fig-3 Indication of the mean line in the Roughness profile. Arithmetic mean deviation (Ra): Represents the arithmetic mean of the absolute ordinate Z(x) within the sampling length. One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-4 shows the indication of the Ra in the surface roughness profile. [5] Fig-4 Indication of the Ra on the surface roughness profile. Root mean square deviation (Rq): Represents the root mean square for Z(x) within the sampling length. This is one of the most widely used parameters and is also referred to as the RMS value. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise. The Fig-5 shows the indication of the Rq in the surface roughness profile. [5] Fig-5 Indication of the Rq on the surface roughness profile. [6] Skewness (Rsk) : The quotient of the mean cube value of Z (x) and the cube of R8 within a sampling length. This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes. The Fig-6 shows the indication of the Rsk in the surface roughness profile. [5] Fig-6 Indication of the Rsk on the surface roughness profile. [6] Kurtosis (Rku): The quotient of the mean quadratic value of Z (x) and the fourth power of Rq within a sampling length. This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects. The Fig-7 shows the indication of the Rku in the surface roughness profile. [5] Fig-7 Indication of the Rku on the surface roughness profile [6] Reference [1] https://guide.digitalsurf.com/en/guide.html [2] https://en.wikipedia.org/wiki/Surface_roughness [3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

I am a colorist with macular degeneration. I receive monthly injections into my left eye. I have been struggling to color and using a "hand held" magnifier until I found this. This is brilliant. I can color anything now. NO PROBLEM getting into intricate areas to color. I wish I would have found this magnifying lamp sooner. Do not hesitate to buy.

[3]Hyun, S. and Robbins, M.O., 2007. Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Tribology International, 40(10-12), pp.1413-1422. [4]https://www.renishaw.com/cmmsupport/knowledgebase/en/surface-finish-measurement–22135 [5] DeGarmo, E.P., Black, J.T., Kohser, R.A. and Klamecki, B.E., 1997. Materials and process in manufacturing. Upper Saddle River: Prentice Hall. [6]https://www.olympus-ims.com/en/metrology/surface-roughness-measurement-portal/parameters/

Ms.Cici

Ms.Cici

8618319014500

8618319014500