Rayleigh Range of Hermite–Gaussian Array Beams - rayleigh range

scratch-dig chart

If you are inspecting scratches and digs in accordance with MIL-PRF-13830B, MIL-C-675C, ANSI/OEOSC OP1.002:2009 (Visibility), or ISO 10110-7 / ISO 14997 (Visibility), then there is only one set currently available for consideration; the plastic moulded Optic Surface Imperfection Scratch-Dig Paddle sold by ThorLabs.

80 50 scratch-dig

In the next section we summarise all of the available (and discontinued) scratch-dig comparison products that are suitable for supporting visibility based optical surface quality assessment; providing you with key information on the options and where you can procure them.

A circular polarizer is designed to do one thing: remove or control reflections from surfaces like water, glass, paint, leaves, sky, buildings, streets, and the list goes on. When light hits those surfaces they create glare that increases highlights, reduces color and detail. Almost every scene contains some kind of glare, and a circular polarizing filter will help you control that glare before it reaches your image.

Leaves from trees and bushes hold glare, especially when wet. By using a polarizer, you can help bring out the colors and textures of foliage.

Scratch and digpaddle

- The options listed are those intended for use when inspecting to the following standards: MIL-PRF-13830B, MIL-C-675C, ANSI/OEOSC OP1.002:2009 (Visibility), or ISO 10110-7 / ISO 14997 (Visibility).

Scratch-dig specifications

When photographing any scene with water in it, there is a large amount of glare. A polarizer helps reduce the glare so that you can see the true color of the water, as well as see through to some of the rocks or other details below the surface of the water.

Glass and windows reflect light and can wash out entire buildings. A circular polarizer reduces or removes the reflections to see what is on the other side.

A circular polarizer darkens blue skies and helps bring out clouds. This helps during both blue sky days as well as cloudy sunsets and sunrises.

Taking a photo of a house or car? Most paints are shiny and reflect more light then needed, which in turn lightens or washes out their color. A Circular Polarizer reduces or removes the reflections for better color.

All polarizers are not created equal and poor quality glass, low quality polarizing films, and bad frames can affect sharpness, resolution, contrast and color. Polarizing glass is made by sandwiching a "polarizing film" between 2 pieces of glass and using special adhesives and manufacturing processes to fuse them into a single unit. If anything is missed during this process, the filter can ruin a great image. Here are features to look for:

A polarizer frame is made of two pieces attached together. One piece holds the glass and the other piece attaches to your lens. Once the filter is secured to the lens, the front piece of the filter will rotate freely. It is this rotation that will allow the photographer to control the polarization effect. By looking through the viewfinder or live screen, begin rotating the filter until you get the amount of reflection removal you need. Depending on the lighting conditions the effect may be dramatic or subtle so it is important to look at the details and the areas that are most important to you to control. Below are examples of common subject where a circular polarizer is used.

Scratch and digapp

mil-prf-13830bscratch and dig

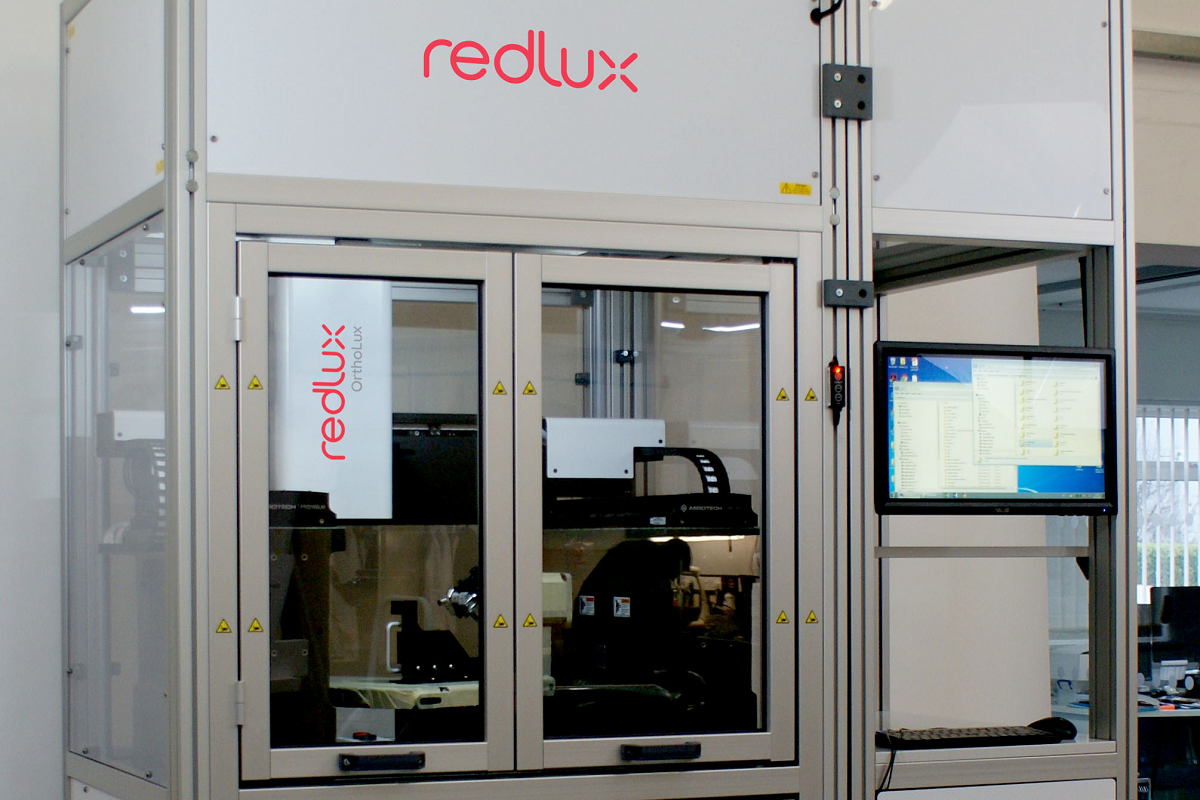

If you would like to receive product information updates on RedLux's Scratch-Dig Comparison References, including release dates, you can register your interest below:

Having found this article, I will assume that you've been on a quest to source scratch-dig comparison sets or paddles, only to discover that the options available are limited at best.

Whether you’re looking to find a better solution, or simply seeking to replace a worn, damaged or lost set, this article has been written to help.

Recognising the importance of having a consistent and reliable source for scratch and dig visual comparison targets, RedLux is working on new set of Scratch-Dig Comparison References based on drawing C7641866. These targets will feature controlled scratches and digs on a glass substrate, making them suitable for both visual inspection and machine vision calibration. They will meet the standards outlined in MIL-PRF-13830B, MIL-C-675C, ANSI/OEOSC OP1.002:2009 (Visibility), and ISO 10110-7 / ISO 14997 (Visibility).

Ms.Cici

Ms.Cici

8618319014500

8618319014500