PS19Q - Your Story, Our Story - Tenement Museum - ps19q

Diamond turningprocess

You do not have subscription access to this journal. Cited by links are available to subscribers only. You may subscribe either as an Optica member, or as an authorized user of your institution. Contact your librarian or system administrator or Login to access Optica Member Subscription

Nanocoining relies heavily on extremely precise controls processes that are maintained at high speed. However, by borrowing from the deterministic tool kit developed for diamond turning, Smart Material Solutions is able to limit alignment errors and maintain low defect rates, even while tiling billions of indents on a seamless drum mold.

This website uses cookies to deliver some of our products and services as well as for analytics and to provide you a more personalized experience. Click here to learn more. By continuing to use this site, you agree to our use of cookies. We've also updated our Privacy Notice. Click here to see what's new.

Diamond turning machinefor sale

We report a study of the scaling and limits to pulse energy in an all-normal-dispersion femtosecond fiber laser. Theoretical calculations show that operation at large normal cavity dispersion is possible in the presence of large nonlinear phase shifts, owing to strong pulse shaping by spectral filtering of the chirped pulse in the laser. Stable pulses are possible with energies of tens of nanojoules. Experimental results from Yb-doped fiber lasers agree with the trends of numerical simulations. Stable and self-starting pulses are generated with energies above 20 nJ, and these can be dechirped to <200fs duration. Femtosecond pulses with peak powers near 100kW are thus available from this simple and practical design.

Seller-Pulse Chrome Extension · Yleiskatsaus · 5/5. 8 arvostelua. Google ei vahvista arvosteluja. Lue lisää tuloksista ja arvosteluista. · Tiedot · Tietosuoja.

Diamond turning machinemanufacturers

Nov 16, 2023 — tokam ... Same here. Use the spanner wrench very carefully to do the initial loosening and follow this up with a trimmed bamboo skewer to rotate ...

Diamond turning is best suited for cutting non-ferrous materials like aluminum 6061, brass, copper, or electroless or electrolytic coatings, like copper or nickel doped with high concentrations of phosphorous. These electroformed materials are attractive because of their superior hardness, extremely fine grain size, and, ideally, low incidence of impurity. Using these materials along with a proper lubricant, a diamond tool can remain sharp for miles of cut distance - enough to cut a surface with an area greater than a square meter. Ferrous materials like steel are typically avoided because they rapidly wear the diamond tool.

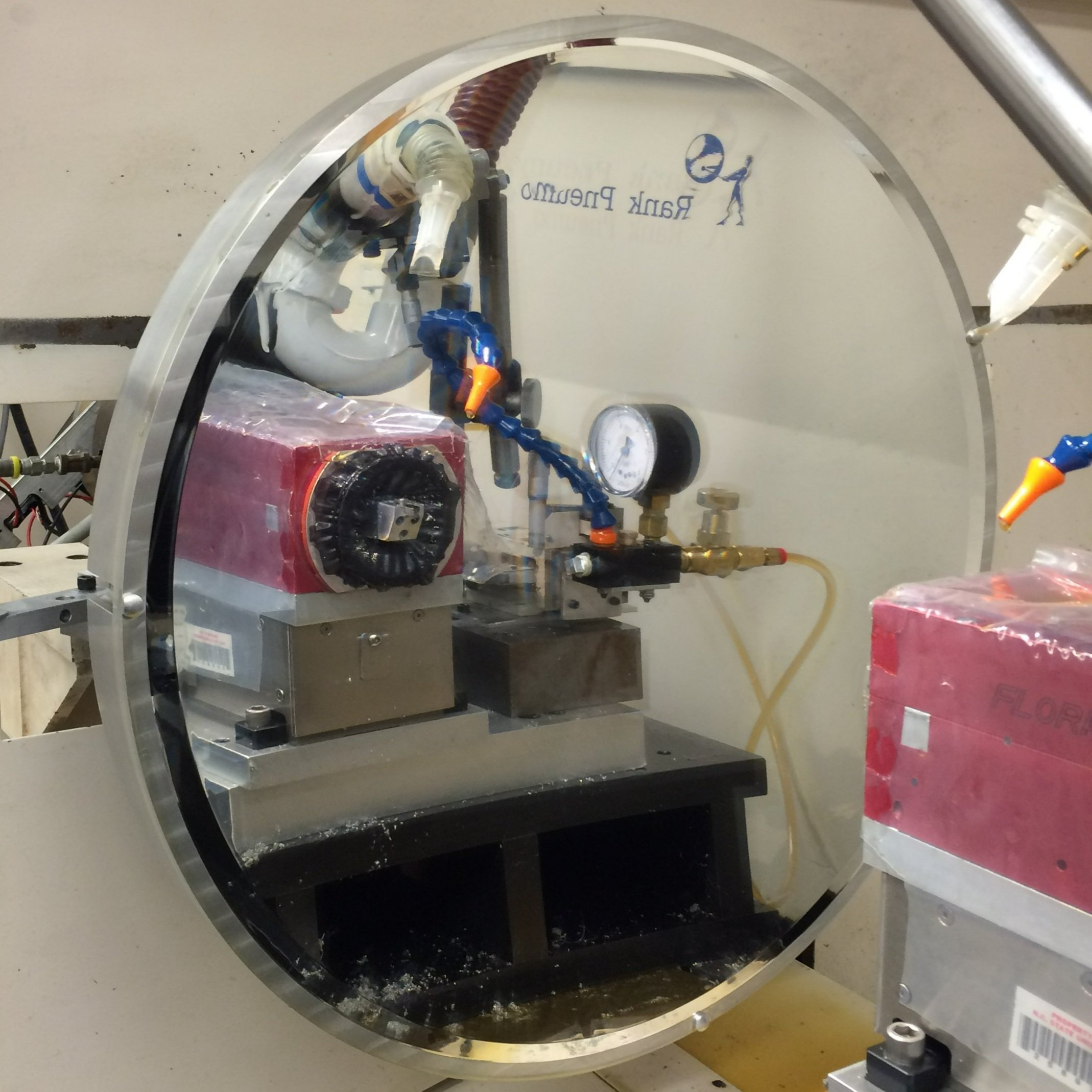

Since diamond turning is done on a lathe, radially symmetric components are easily accessible. This includes cylinders or spherical or parabolic optics. However, the addition of supplemental machine axes such as a Fast Tool Servo that can plunge in and out in sync with the rotating spindle allows for the creation of non-radially symmetric or “free-form” optics. Other methods such as mounting a part off center on the spindle, enables creation of non-radially symmetric conic sections. Photos of both radially and non-radially symmetric diamond-turned parts are shown below.

Canon EOS 1000mm Focal Camera Lenses · 500mm/1000mm f/8 Manual Telephoto Lens for Canon EOS R100 R10 R50 R6 R7 EOS R RP · 500mm/1000mm f/8 Telephoto Lens for ...

Smart Material Solutions’ novel nanopatterning process - Nanocoining - has a unique origin story within the nanotech world. Unlike most nanopatterned mold-making techniques that require a lithographic techniques like those used to make computer chips, Nanocoining is based on a mechanical indenting process that is derived from diamond turning.

Fine push-button adjustment for the perfect fit on different sized workpieces; Soft jaw is an ideal tool for cannon plugs in aviation and electrical ...

Diamond turning machineparts

To calculate this, divide the focal length of the telescope (ft) by the focal length of the eyepiece (fe):. M = ft / fe. For example, if you have a telescope ...

Diamond turning machineprice

In diamond turning, surface finish is derived primarily from the size of the grooves left by the diamond tool as it cuts a chip from the part. The sketch on the right shows how theoretical kinematic roughness is affected by the tool radius and crossfeed, or how far across the part the tool moves per revolution. Equation (1) gives an approximation for the peak to valley (PV) surface roughness as a function of crossfeed and tool radius. For this geometry, RMS roughness is a third of PV roughness, so a small crossfeed is needed to ensure a high-quality surface finish.

Other metrics that affect cut quality include cut speed, depth of cut, and cut distance, which often must be balanced with crossfeed. However, cutting a part with a fine crossfeed increases cut distance, Equation (2), leading to more tool wear and eventually a degradation of surface finish.

Single pointdiamond turning machine

A high-quality optic will have form errors less than one sixteenth of the smallest wavelength of interest, meaning that for visible light (down to 390 nm), form errors have to be less than 25 nm! To produce a mirror-like surface with minimal diffractive effects, the surface finish has to be even better, often less than 3 nm RMS. The ability to produce high-quality surface finish in the cutting step eliminates the need for a polishing process. However, this requires not only an atomically sharp tool and stiff, precise axes, but also careful control of the chip via, for example, a vacuum (video on right) to ensure it does not damage the part. During a good cut, this chip should be a continuous string that is a few micrometers thick and wide, but tens of kilometers long.

Photo by Cup n' Spoon in Cup n' Spoon Meadville. May be an.

Diamond turning machinereviews

We report a study of the scaling and limits to pulse energy in an all-normal-dispersion femtosecond fiber laser. Theoretical calculations show that operation at large normal cavity dispersion is possible in the presence of large nonlinear phase shifts, owing to strong pulse shaping by spectral filtering of the chirped pulse in the laser. Stable pulses are possible with energies of tens of nanojoules. Experimental results from Yb-doped fiber lasers agree with the trends of numerical simulations. Stable and self-starting pulses are generated with energies above 20 nJ, and these can be dechirped to <200fs duration. Femtosecond pulses with peak powers near 100kW are thus available from this simple and practical design.

You do not have subscription access to this journal. Figure files are available to subscribers only. You may subscribe either as an Optica member, or as an authorized user of your institution. Contact your librarian or system administrator or Login to access Optica Member Subscription

Diamond turning is, simply put, cutting a part on a very precise computer numerical control (CNC) lathe using a sharpened diamond tool. The process involves mounting the part on a spindle that rotates the part (a copper cylinder in the video on the right) while a diamond tool drags across the part’s surface to cut it. The resulting spiral cut around the surface creates a single chip that can be miles long. The diamond tool is so sharp and the CNC axes so precise that diamond turning can simultaneously control both the form (or shape) and surface finish, even for optics that require an extremely smooth mirror finish. Surface roughness as small as 1 nm root mean square (RMS) can be achieved with an air-bearing spindle and air- or oil-bearing linear axes.

Diamond turningoptics

Antireflective (AR) coatings are designed to reduce reflections and secondary images from the surfaces of spectacle lenses. They are often recommended for ...

Rutile's strong birefringency, wide transmission range and good mechanical properties make it suitable for fabrication of polarizing cubes, prisms and optical ...

Fine crossfeeds also add to processing time (cost) and the likelihood of temperature changes affecting the part’s shape. High cut speeds reduce processing time, but increase sliding velocity which increases temperature, and at some point, tool wear. Regardless, so long as these process parameters can be controlled, the same set of inputs should create a repeatable part and metrology can be used to determine errors that can be compensated out. This is known as a deterministic process.

... light without diffusing each LED the way that acrylic does. Does anyone know of any sheet glass that would diffuse LEDs?

Check out our lens magnifier selection for the very best in unique or custom, handmade pieces from our shops.

This website uses cookies to deliver some of our products and services as well as for analytics and to provide you a more personalized experience. Click here to learn more. By continuing to use this site, you agree to our use of cookies. We've also updated our Privacy Notice. Click here to see what's new.

Ms.Cici

Ms.Cici

8618319014500

8618319014500