Potassium bromide - kbr solubility in water

lp/mm calculator

Better zooming and cropping capabilities: With increased resolution, users can zoom in and crop images without significant loss of quality or detail.

Computational imaging and deep learning: Artificial intelligence and machine learning techniques are being explored to enhance resolution and line pair performance through advanced image processing and reconstruction algorithms.

SRP’s reflector directs nearly 100% of all energy from the tube into the space, and is the most efficient reflector in the industry. We have incorporated materials that have high emissivity and utilize 10 reflective surfaces at critically controlled angles to accomplish this. Additionally, our reflector extends completely below the bottom of the tube.

Remote sensing and aerial imaging: In applications like satellite imagery, aerial photography, and environmental monitoring, spatial resolution is crucial for capturing fine details and accurately mapping terrain and features. Line pairs are used to assess and optimize the resolution of these imaging systems.

Sensor and display limitations: Different sensor and display technologies may have inherent limitations in terms of their ability to resolve line pairs and achieve high resolutions.

Can a higher number of line pairs always guarantee better resolution?While a higher number of resolvable line pairs per millimeter generally indicates better spatial resolution, other factors such as contrast, noise, and image processing can also influence the perceived resolution and image quality.

Line pairs are essential in imaging and display technologies because they provide a standardized way to evaluate and compare the performance of different devices. They help ensure consistency and allow manufacturers to optimize their products for optimal image quality.

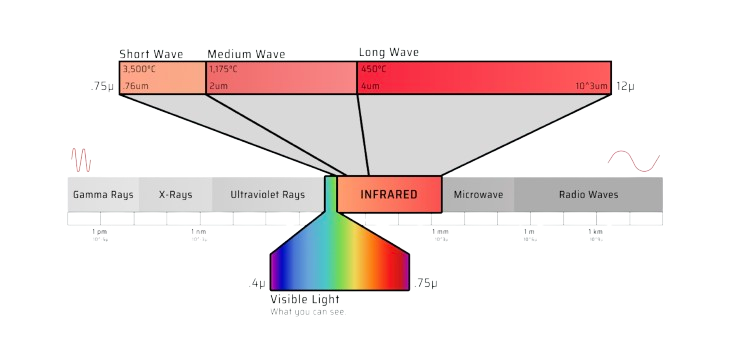

Spectral resolution: This refers to the ability of an imaging system to distinguish between different wavelengths or colors. It is crucial in applications like remote sensing and hyperspectral imaging.

Line pairs per millimeterconverter

Sharper and more detailed images: Higher resolution allows for the capture or display of finer details, resulting in sharper and more realistic images.

On a properly designed “deep dish” infrared reflector system, such as used by SRP, the amount of convection loss directly from the reflector is very small (estimated to be between 1 and 3% of the total input of the appliance, depending on firing rate). Reducing this small amount by even 25% is virtually insignificant. These small changes DO NOT affect the radiant output of the tube – as the tube temperatures are determined by design to be as high as practical, and as allowed by the appliance approval standard. It is the marriage of the burner, tube and reflector system (“fixture efficiency”) that ultimately determines how much useable radiant energy leaves the appliance. As an illustration of this, radiant factor testing according to EN-419-2 has shown SRP’s standard reflector system to be >5% more effective than competitive insulated reflectors and >44% more effective than the same competitor’s uninsulated reflector.

Can improving resolution through line pair optimization lead to any negative consequences or trade-offs?Yes, improving resolution through techniques like oversampling or super-resolution algorithms can sometimes lead to trade-offs in other aspects, such as increased processing requirements, higher data storage needs, or potential limitations in dynamic range or color accuracy.

As technology continues to evolve, our understanding and optimization of the relationship between line pairs and resolution will play a critical role in enabling better imaging and display capabilities across various industries and applications.

How do different sensor technologies (e.g., CCD, CMOS, etc.) affect the relationship between line pairs and resolution?Different sensor technologies may have varying abilities to resolve line pairs and achieve high resolutions. Factors like pixel size, noise characteristics, and sensor architecture can influence the relationship between line pairs and resolution for a particular sensor type.

Temporal resolution: This refers to the ability of an imaging system to capture or display moving objects without blur or distortion. It is particularly important for video and motion-based applications.

While line pairs are primarily used to measure resolution, they can also be employed to improve and enhance the resolution of imaging systems. By carefully analyzing and optimizing the line pair performance, manufacturers can implement techniques such as oversampling, super-resolution algorithms, and advanced image processing to achieve higher effective resolutions.

Practical limitations: In some applications, such as consumer electronics or low-cost imaging systems, there may be practical limitations in terms of cost, power consumption, or physical size that restrict the achievable resolution and line pair performance.

Resolution refers to the ability of an imaging system to capture or display fine details. It is typically measured in pixels per inch (PPI) or dots per inch (DPI) for digital displays and printers, respectively. Higher resolution means more pixels or dots per unit area, resulting in sharper and more detailed images.

Spatial resolution: This refers to the level of detail that can be captured or displayed in an image. It is closely related to line pairs and is often the primary focus when discussing resolution.

At Superior Radiant Products, we are committed to creating innovative infrared heating solutions for our global partners. We believe that through the power of efficient solutions, we have the ability to save energy and move the needle towards a more sustainable world.

Line pairs per millimetercalculator

The relationship between line pairs and resolution is an area of active research and development, with ongoing efforts to improve imaging and display technologies. Some potential future developments include:

When evaluating the resolution of an imaging system, manufacturers often use line pair test patterns. These patterns consist of alternating dark and light lines of varying frequency (line pairs per millimeter). By determining the highest frequency of line pairs that can be clearly distinguished, the spatial resolution of the system can be quantified.

Despite these challenges, ongoing research and technological advancements continue to push the boundaries of resolution and line pair performance, enabling better imaging and display capabilities across various industries.

In recent years, some competitors have begun insulating their reflectors. These more expensive configurations can help reduce the overall convective loss from the reflector material by reducing the temperature of the surface subject to convective heat exchange, but they do nothing to improve the “bounce back” deficiencies as discussed and illustrated above. This is because infrared energy responds to all the same optical mechanisms as other forms of electromagnetic energy, making the physical shape and the inherent material properties (reflectivity) of the reflector most important in determining how efficiently radiated energy leaves the appliance and is directed into the space.

Contact us today to learn more about our cutting-edge X-ray inspection systems and how they can benefit your manufacturing process. Let Wellman be your partner in your product inspection process.

Are line pairs only relevant for spatial resolution, or do they also relate to other types of resolution?Line pairs are primarily used to measure and evaluate spatial resolution. For other types of resolution, such as temporal or spectral resolution, different measurement techniques and metrics may be employed.

Imaging systems: Line pairs and resolution are essential considerations in the design and evaluation of cameras, scanners, displays, and other imaging devices. They help ensure that these systems can capture or display high-quality images with adequate detail and sharpness.

Line pairs permm radiology

In summary, the SRP reflector system incorporates highly reflective materials in a superior “deep dish” design configuration to release ~100% of the radiant energy produced by the tube to the space, while minimizing convective losses. This combination of technological innovations results in SRP heaters with radiant outputs (percentage of input energy converted to radiant energy and released to the space) comparable, and in many cases, superior to any tube heater in the market.

Addr: 5F, B3, Anda Electronics Industrial Factory, Heping Community, Fuhai Street, Baoan District, Shenzhen Call Us: +86 13699888264 Email: sal@es9@@well@-man.com

lp/mm to resolution

Advanced sensor and display technologies: Emerging technologies like quantum dot displays, microLED arrays, and novel sensor architectures may enable higher resolutions and improved line pair performance.

Enhanced printing and display quality: High-resolution images and displays provide better print quality and more vibrant and accurate on-screen representations.

In the world of imaging and display technologies, two terms often come up: line pairs and resolution. While these concepts may seem technical and abstract, they play a crucial role in determining the quality and clarity of the images we see. Whether you’re a photographer, graphic designer, or simply someone who appreciates sharp visuals, understanding the relationship between line pairs and resolution can help you make informed decisions and get the most out of your devices.

For comparison purposes, the diagrams in Figure 1 on the previous page clearly show the advantage of SRP’s reflector design as compared to popular competition models.

Virtual and augmented reality: High-resolution displays and imaging systems are crucial for creating immersive and realistic virtual and augmented reality experiences, driving the need for continued advancements in line pair and resolution performance.

Can line pairs be used to assess resolution in non-imaging applications, such as audio or signal processing?Line pairs and resolution are concepts primarily used in imaging and display technologies. While there may be analogous concepts in other fields like audio or signal processing, the specific terminology and measurement techniques may differ.

Technical challenges: Accurately measuring and resolving line pairs at very high frequencies can be technically challenging, requiring advanced optics, sensors, and processing capabilities.

However, it’s important to note that the relationship between line pairs and resolution is not always linear. Various factors, such as the contrast between the lines, the sharpness of the edges, and the presence of noise or artifacts, can influence the perceived resolution and the ability to resolve line pairs accurately.

The resolution of an imaging system is influenced by various factors, including the quality of the optics, the sensor or display technology, and the processing capabilities of the device.

Perceptual factors: The human visual system has its own limitations, and beyond a certain point, increasing resolution may not provide a noticeable improvement in perceived image quality.

Line pairs and resolution are closely related, with line pairs being a direct measure of spatial resolution. The more line pairs per millimeter that an imaging system can resolve, the higher its spatial resolution and the finer the details it can capture or display.

The relationship between line pairs and resolution is a fundamental concept in imaging and display technologies. Line pairs provide a standardized way to measure and quantify spatial resolution, allowing for the evaluation and comparison of different imaging systems. By understanding this relationship, manufacturers can optimize their products for better image quality, sharper details, and enhanced overall performance.

Medical imaging: In fields like radiology and pathology, high-resolution imaging is critical for accurate diagnosis and treatment. Line pairs and resolution play a vital role in ensuring that medical imaging systems, such as MRI, CT, and X-ray machines, can produce clear and detailed images for analysis.

Gas fired infrared heating appliances are available from a variety of manufacturers, each with their own design nuances and performance claims. Although many factors of the design influence radiant performance of the heater, one of the most critical considerations is the reflector design. This article outlines the reflector as a component for maximum performance as found in Superior Radiant Products (SRP) heating equipment.

2. Trap air near the heat exchanger, to prevent a flow of air from “cooling” the tube temperatures, and hence de-creasing the radiant output from the tube. As an example, if a 1000°F tube is cooled just 10% to 900°F, the loss in radiant output is approximately 25%! Higher tube temperatures produce a larger percentage of radiant energy (versus convected energy).

Lp/mm to micron

Together with a full profile end cap on the reflector, our reflector system minimizes the convective loss from the heat exchanger by trapping as much heated air around the tubing as possible. This “deep dish” design is critical for proper performance of the heater.

Multispectral and hyperspectral imaging: As imaging applications expand into new spectral domains, the relationship between line pairs and resolution will need to be explored and optimized for these specialized imaging modalities.

Line pairs per millimeterchart

Insulating the reflector also does very little to improve the amount of “dead air” space that surrounds the tubing; this is a function of the “deep dish” nature of the reflector design, and the use of end caps etc. to prevent the air warmed by the tube from spilling into the space.

Line pairs permm and pixel size

1. To redirect as much radiant energy as possible into the space after it leaves the heat exchanger tube – to do this in the most efficient manner possible, the energy should not “rattle around” under the reflector, repeatedly bouncing between the tube and reflector, but rather should bounce off the reflector and then leave the appliance; and

At Superior Radiant Products, we are committed to creating innovative infrared heating solutions for our global partners. We believe that through the power of efficient solutions, we have the ability to save energy and move the needle towards a more sustainable world.

Line pairs refer to a pattern of alternating dark and light lines used to measure the resolving power of imaging systems. Essentially, they act as a reference for determining how well an imaging device can capture or display fine details. The higher the number of line pairs per millimeter (lp/mm) that can be distinguished, the better the resolution of the system.

While the relationship between line pairs and resolution is well-established, there are certain challenges and limitations to consider:

Additionally, some competitors argue for “polished” surfaces as an improvement over “mill finished” surfaces. Polished surfaces may have an effect on visible light, but they do not improve the reflectivity of a reflector versus “mill finished” surfaces for infrared wavelength energy. Overall reflectivity of the material is what matters and SRP utilizes aluminum, which has very high reflective properties.

Whether you’re a professional in the imaging or display industry, or simply someone who appreciates clear and detailed visuals, grasping the significance of line pairs and resolution can help you make informed decisions and appreciate the technological advancements that continue to shape our visual experiences.

However, it’s important to note that improving resolution through line pair optimization often comes with trade-offs, such as increased processing requirements, higher data storage needs, and potential limitations in other aspects like dynamic range or color accuracy.

Ms.Cici

Ms.Cici

8618319014500

8618319014500