Popular Lens Mounts Used in Embedded Vision - c mount vs cs mount

However, a pair of prescription polarised sunglasses is a very effective solution, although naturally not the most useful for night-time activities.

This is what they were designed for, but innovation and technological advancements mean that glasses can also improve your visual experience in other ways, such as blocking out blue light or reducing glare.

anti-reflective coating是什么

It’s easy to avoid looking directly at a bright light source, but glare is harder to escape. Glare is defined as a strong, dazzling light.

The most noticeable benefit of anti-reflective coatings is the improved appearance of the lenses. Without reflections, the wearer’s eyes are more visible, making conversation and eye contact in general easier.

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.

At Diamond Coatings, we’re passionate about pushing the boundaries of touch technology. We’re not just manufacturers – we’re innovators

SmartBuyGlasses™ is a leading independent retailer of the world’s best designer eyewear since 2006 and is not owned by or affiliated with the brands it sells unless stated otherwise. All trademarks and brand names shown on our pages are the property of their respective companies which retain all rights.

Every anti-reflective coating gives the lenses it’s applied to a very subtle tint. This tint is most often either green, brown or yellow.

Development of AR coatings continued over the coming decades and in 2002, Diamond Coatings established its first ITO and AR Coating manufacturing plant in the Midlands, UK. Operations were expanded to Arizona, USA in 2016 and today, Diamond Coatings is a leading supplier of AR & ITO coatings to world-wide industries including:

anti reflective coating中文

Light is essential for vision, but too much light causes problems for our eyesight. We don’t tend to look directly at sources of light, as it can hurt our eyes and cause discomfort.

The surface tarnish replaced the interface between air and glass with two new, air-tarnish and tarnish-glass interfaces. Due to the tarnish having a refractive index between glass and air, these two interfaces each exhibited less reflection than a clean air-glass interface. The total of these two interfaces’ reflections is, in fact, less than the reflection of a ‘naked’ interface between air and glass, which can be calculated via the Fresnel Equations.

Before going into the history of AR coatings, allow us to begin by looking at what exactly an anti reflective coating is…

As is usually the case when it comes to eyewear choices, your own vision requirements and lifestyle will dictate what the best option for you is.

Ask your optician to recommend which cleaning products can be safely used to clean your anti-reflective glasses. The harsh chemicals in some products can damage the coating.

When it comes to sunglasses, the dark lens tint generally negates the need for an AR coating on the outside of the lenses. It can still be applied on the inside of the lenses, however, for greater comfort when the sun is behind you.

While there are different methods of introducing anti-glare properties, it’s important to use the right names for them in order to avoid confusion.

Some retailers talk about anti-glare coating for glasses, but in reality, this does not exist. It might sound like they’re the same thing, but anti-reflective coating is the correct term for this treatment.

The first, and simplest, type of AR coating was discovered in 1886 by British Physicist and Nobel Prize Winner (physics, 1904) John William Strutt, 3rd Baron Rayleigh (Lord Rayleigh). Upon testing some old, tarnished glass pieces (chemical reactions between the environment and the optical glass of his time tended to cause surface tarnishing on glass as it aged), Lord Raleigh found that – to his surprise – these tarnished pieces transmitted more light than clean, new pieces.

Opticalcoatingprocess

Surfaces like glass, water, snow, and certain metals are highly reflective, so we often experience glare from them, making it more difficult to view other objects close to where the glare is coming from.

At Diamond Coatings, we take pride in being a leading TCO films supplier, specialising in the deposition of high-quality ITO.

Like with any glasses, always use a microfibre cloth to clean anti-reflective lenses instead of a t-shirt, tissue, or other type of material that could cause tiny abrasions.

Continually developing new coatings – many of which are designed specifically to meet client-specific requirements – Diamond Coatings uses state-of-the-art technology to vacuum deposit these coatings onto virtually any flat or shaped substrate, including injection-moulded parts. Learn more/discuss your AR coating requirements today by contacting our helpful, innovative team of experts now.

Despite this, usage of the term “anti-glare coating” persists. The lens technology that most accurately fits the description of “anti-glare glasses” would be polarization, although it is only available for sunglasses lenses.

If you struggle with the headlights of oncoming traffic when driving at night, an AR coating would also help in that regard. If your goal is to have anti-glare glasses, then polarised sunglasses will do a great job of achieving that.

Contrary to what you may think, an anti-reflective coating can actually make your glasses easier to clean and care for. Most AR coatings have a hydrophobic finish, which repels water and dirt, so the lenses don’t smudge so easily.

Opticalcoating

Different coatings can add impact resistance, hydrophobic qualities, UV protection to your glasses, shield your eyes from blue light, and help with glare.

Frustratingly for optical experts and linguistic pedants alike, the discussion about “anti-glare glasses” and “anti-glare lenses” is very often littered with misused language.

Uncoated lenses allow about 92% of light to pass through them. An anti-reflective coating increases that to 99%, giving the wearer greater visual acuity.

anti-glare什么意思

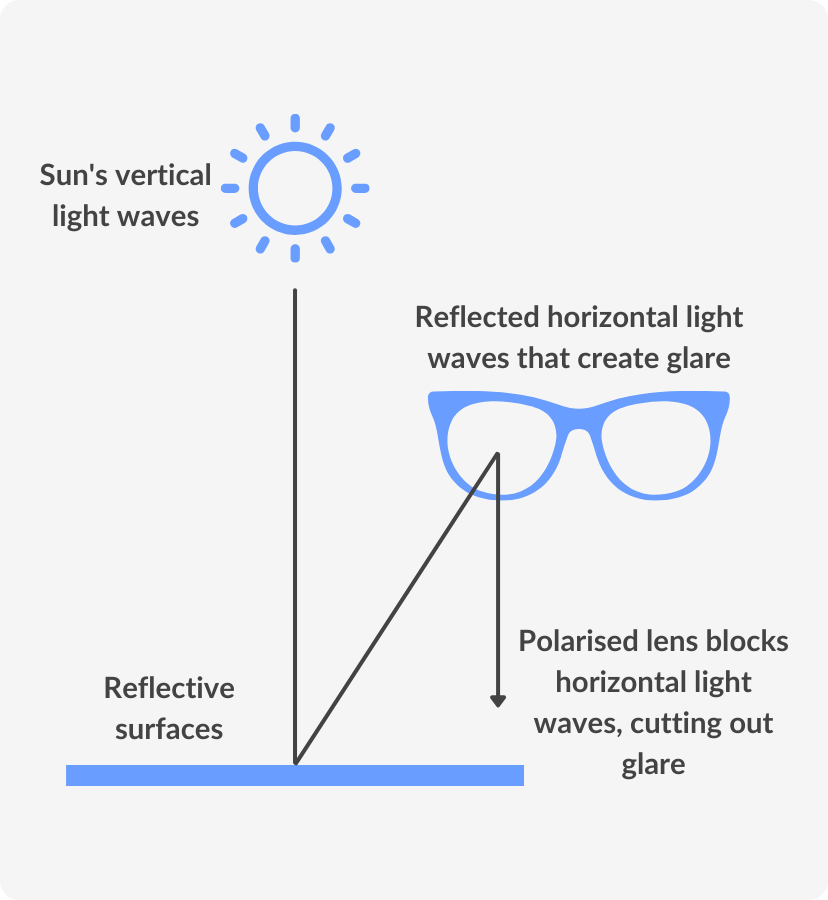

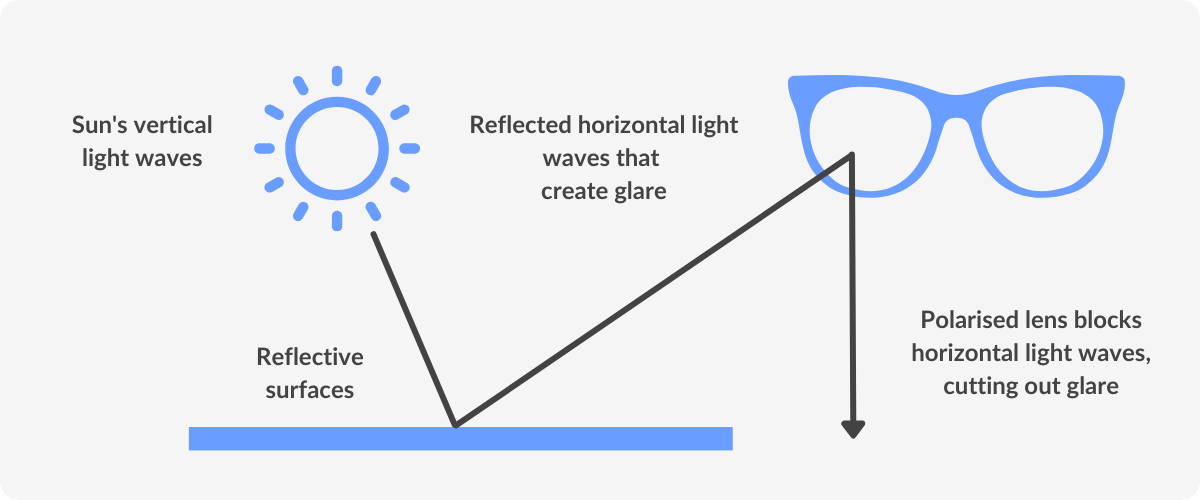

This greatly reduces glare for the wearer, and provides much sharper vision contrast. The chemical used in the polarisation process results in heavily tinted lenses, which makes it unsuitable for eyeglasses.

Speak to your optician for personalised recommendations on which solution is right for your specific needs, or you can ask our opticians for further advice.

The halos that form around bright lights are also removed from your view with an anti-reflective coating, making driving at night more comfortable. With a greater amount of light reaching your eyes, an AR coating also improves visual acuity.

Although it is necessary to specify wavelength ranges when designing/ordering anti reflective coatings, good performances can frequently be achieved for comparatively wide frequency ranges. Choices offered usually include IR (infra-red), visible and UV (ultra-violet). The question is, where did it all begin?

Is an anti-reflective coating worth the investment? If improving the appearance of your glasses is a priority for you, then absolutely.

The most effective anti-glare glasses are those fitted with polarised lenses. Polarised lenses work by filtering out horizontal light waves, while allowing vertical light waves through.

Let’s take a closer look at electrically conductive plastics and explore how we utilise Indium Tin Oxide (ITO) coating technology to unlock their potential.

A secondary advantage of AR coatings is that they generally have a hydrophobic finish to seal all of their layers, making them water-repellent and easier to clean.

Anti reflective Screen Protector

As the name suggests, anti reflective (AR) coatings are optical coatings applied to the surfaces of optical elements, lenses, etc. to reduce reflection. Improving the efficiency of typical imaging systems (reduced reflections means reduced loss of light), AR coatings also improve complex systems’ (microscopes, telescopes, etc.) contrast of images by eliminating stray light, which is particularly important for planetary astronomy.

Elimination of reflection is itself the primary benefit for many applications, including, for instance, coatings to reduce the glint from telescopic sights or the binoculars of covert viewers, and coatings on the lenses of eyeglasses.

An anti-reflective coating is particularly useful on high-index lenses, as these can reflect up to 50% more light than other lenses. This makes an anti-reflective coating indispensable.

Anti-reflective lens coatings also improve visual acuity, meaning your vision will be sharper, thanks to the extra light getting through to your eyes.

Anti-fingerprint coatings create a barrier against everyday marks, ensuring that your devices, and other surfaces, remain pristine and clear.

The main purpose of an anti-reflective (AR) coating is to prevent reflections on the outer surface of glasses lenses by allowing more light to pass through them.

Surfacecoating

The difference between polarised lenses and anti-reflective coating is that polarisation prevents you from seeing glare at the source, while an anti-reflective coating prevents you from seeing glare reflected on your lens surface.

The more light that reaches your eyes, the more clearly you see. This is all achieved by a fairly complex scientific process called the optical interference model.

Of particular benefit is the large size of the parts that Diamond Coatings can apply AR coatings to. We can anti-reflect parts up to 1m x 1m, which is much larger than typical for the coating industry.

Consisting of thin transparent film structures, many AR coatings have layers of alternating contrasting refractive indexes. The thickness of layers is selected to generate destructive interference within beams reflected from interfaces, as well as constructive interference within corresponding transmitted beams. Making the structure’s performance alter with incident angles and wavelengths, this frequently causes colour effects to appear at oblique angles.

In 1904, a chemical method of producing AR coatings was developed by British inventor/optical designer Harold Dennis Taylor (Cooke Company), followed by the invention and development of:

As you’re undoubtedly well aware, the main function of glasses is to allow you to enjoy a clear, sharp field of vision, and therefore live your life in greater comfort.

Arcoating

Both polarised lenses and anti-reflective coating have their benefits, with one potentially more suited than the other to the types of settings you’ll most often find yourself in.

Basically, the layers of the anti-reflective coating work together to introduce “destructive” light waves, that, as their name suggests, destroy reflections on the lenses.

Disclaimer: Anti-reflective coatings on glasses lenses can provide a more comfortable viewing experience, but do not eliminate 100% of glare.

AR coatings are made of layers of metal oxides. Simply put, an anti-reflective coating cancels out the light reflection on the surface of the lenses and allows more light to pass through them and reach your eyes.

These pesky reflections are an aesthetic concern for some, as reflections on the front of their glasses hide their eyes from view, ruin photographs, and are also often noticeable during video calls.

For the wearer, the absence of reflections on their lenses is less distracting, especially in situations such as driving at night, working in a brightly lit environment, or in front of digital screens. Your eyes are put under less strain as a result.

Ms.Cici

Ms.Cici

8618319014500

8618319014500