Polarization of Light - Definition, Types, Methods, & ... - linearly polarised light

Laser gaussian beampdf

Gaussian beamwaist

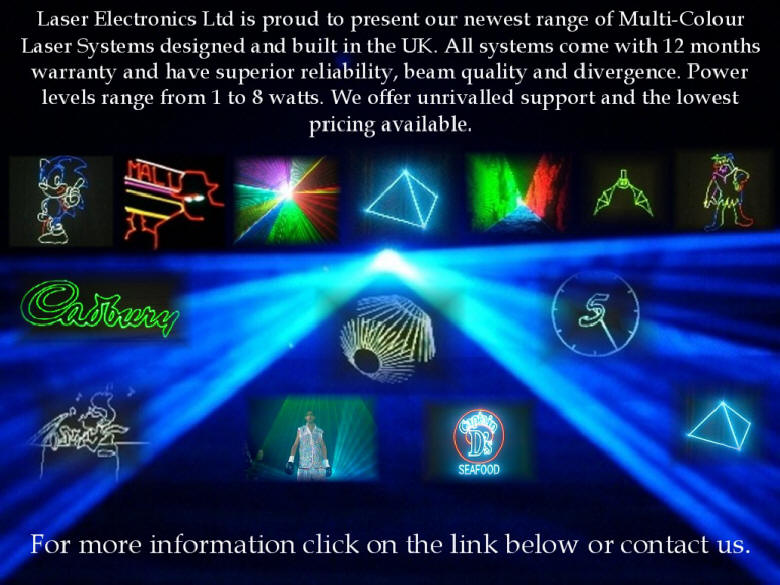

Laser Electronics Ltd can also offer repair services to other types of electronic equipment such as Audio equipment, Lighting equipment and Multimedia equipment (Video recording LCD and Plasma Screens) as well as High End Computer related systems.The on-going development of new products and the ability to upgrade the systems we produce has guaranteed continuing success throughout the world. Prestigious installations in India, Greece, Spain, Ireland, Indonesia, Brazil, America and England (plus many others) have kept Laser Electronics Ltd at the forefront of the laser and multimedia industries. Our latest developments include new low cost high reliability Multi Colour laser systems that surpass those of our competitors. We have added new software versions for all of our software products and these are available free of charge to all our existing customers as well as downloadable demos of our software products, the addition of High Quality low cost Scanning systems and the completion of our new USB and Network laser hardware interfaces. To our range of products we have developed and added the worlds easiest to use lighting controller software (LEDMX) and free software for laser users to view ILDA format files directly on their computer.Please browse our website to see how we can generate revenue for your business and keep you the customer at the forefront of the latest technology and lowest running costs.

Although it is inexpensive, this method is time-consuming, so you have to wish that your laser is stable enough so that its M2 value doesn’t fluctuate while you are taking the various diameter measurements! A simple way to increase the acquisition speed is to mount the beam profiler on a motorized translation stage and automate the acquisition.

Gaussian beamintensity formula

One nice thing about M2 is that it is dimensionless (i.e. no units of measurement), which makes it simpler to compare different lasers. On the other hand, it’s a bit counter-intuitive, but lower values of M2 indicate better quality than higher values. In fact, the best possible result is M2 = 1, and as the value of M2 increases, the quality of the laser decreases. To have a better grasp on how quickly the M2 value can affect your spot size or beam diameter in the near field, check this calculator of ours, it is an efficient and instructive test bench.

A collimator sight is a type of optical sight that allows the user looking into it to see an illuminated aiming point aligned with the device the sight is ...

At the most basic level, all you need is a lens, a beam profiler and a ruler. You can read our application note that explains step-by-step how to measure beam profile quality with these basic tools and calculate the laser beam quality result using our free software.

Gaussian beamdivergence

Portable laser power meter for up to 250 W with flexible calibration options so the customers only pay for what they use. Includes 3 measurement modes : SSP, CWP and SSE.

Gentec-EO's high-accuracy laser beam measurement instruments help engineers, scientists and technicians in all sorts of laser applications from the factory to the hospital, laboratory and research center. Learn about our solutions for these measurement types:

Now that you know more about laser beam quality measurement, you will have a better idea of whether it is actually what you need to measure. Keep in mind that M2 is an indicator of how close your laser beam is to the ideal TEM00 Gaussian beam.

That’s it! You now understand the fundamentals of M2 measurement… Any questions? Feel free to comment below or contact us, we will be happy to answer!

The ISO norm explains a method to calculate M2 from a set of beam diameter measurements, in a way that minimizes sources of error. Here are the main steps:

You might wonder (and many people do), how close is your real-life laser to perfection? In this guide, we will introduce you to the concept of laser beam quality measurement with the M2 parameter, which quantifies the laser beam quality, and how to measure M2 for a real laser.

It is also common practice in systems with fiber optics to look for lasers with an M2 close to 1 to allow for good coupling with single-mode fibers. The beam waist for a real beam is defined as:

And how far do you need to go to be in the far field to measure the divergence? Are these two data points enough? The folks at the International Organization for Standardization, or ISO, decided to put an end to all this confusion, so they wrote a norm explaining how to measure and calculate M2 properly: ISO 11146.

Receiver Operating Characteristic (ROC) curve. The X axis is false positive rate (FPR), Y axis is true positive rate (TPR). For certain classifier, we can get a ...

What Siegman proposed is to use a dimensionless value for laser beam quality, by dividing a real laser’s BPP with the one from an ideal laser. We therefore obtain a ratio that indicates how close your laser beam is to the perfect Gaussian beam, and Siegman called this value M2 (pronounced m-squared).

Laser specifications change over time for many reasons and it causes problems accross all industries. Learn about how laser output measurement solves numerous problems in YOUR industry. Download the guide below.

Ideal Gaussian beams have the smallest BPP for a given wavelength. Since we know that θideal = λ / (π w0,ideal ), the BPP for an ideal beam simplifies to BPPideal= λ / π. While it is simple to calculate, the BPP is not the best tool to compare one laser with another, because its ideal value changes with the wavelength.

If you are trying to develop a laser with nondiffractive beams like Bessel beams, or higher-order Gaussian beams with donut profiles, or more simply a top-hat beam, M2 is not an indicator that you should be aiming for. It would not really make sense nor be of great usefulness. For some applications, knowing only the beam divergence would be enough and far more relevant.

Gaussian beampropagation

In the equation above, you can see that lasers with a high M2 diverge more rapidly than lasers with a low M2. Laser manufacturers like to provide the M2 factor in their specifications because it gives the users an idea of how easy it will be to work with their laser.

But in real life, nothing is perfect, and a pure Gaussian beam with a TEM00 profile and a bell-shaped curve that spreads on infinitely is, unfortunately, never achieved.

A laser generates a beam of very intense light. The major difference between laser light and light generated by white light sources (such as a light bulb) is ...

Meaning, is it Death Star material or more of a “I can annoy you with my laser pointer” material. But, in more practical terms, focusing laser beams tightly is particularly important when the application at hand is imaging, manufacturing, or destroying planets at a distance. Smaller beam waists mean having a better resolution as well as the possibility of reaching higher power densities.

2014108 — When light from a point source goes through a correctly powered spectacle lens yet fails to create a perfect image, the cause is lens aberration.

The ISO norm also states a few extra rules about the measurement of diameters (especially when using array sensors such as CCD or CMOS sensors):

Laser specifications change over time for many reasons and it causes problems accross all industries. Learn about how laser output measurement solves numerous problems in YOUR industry. Download the guide below. Gentec-EO's high-accuracy laser beam measurement instruments help engineers, scientists and technicians in all sorts of laser applications from the factory to the hospital, laboratory and research center. Learn about our solutions for these measurement types: Laser power meters Laser energy meters Laser beam profilers Terahertz power meters

Laser power detector for measurement up to 50 000 W that traps > 97 % of the incident light and handles high intensities of small beams.

Laser Electronics Ltd was formed in 1992 and is a small High Technology Electronics company based in Skegness, Lincolnshire, England. We specialise in the design and manufacture of software and hardware for Laser Light Show entertainment, Lighting applications, Multimedia, Scientific, Medical, Research and Industrial applications. Over the past 22 years we have become a leader in the Laser Light Show, Research, Medical and Multimedia industries, we have the track record and necessary expertise to provide you (the client) with the innovation of high technology bespoke systems. All aspects of our systems are engineered to the highest specification, with all equipment built and tested at our premises here in the UK so that you can be assured of a quality UK product, tailored for your application designed, built and backed here with full technical support here in the UK.We only use the highest specification components to manufacture reliable products that are created with originality and safety in mind.

Laser gaussian beamcalculator

Siegman’s proposal became popular because of its simplicity, but experimentally it isn’t so straightforward, and some uncertainties arise from these principles. For example, if you want to measure the waist radius in the lab, how can you be sure that your measurement device is positioned exactly at the focus?

Basically, it comes down to checking how your real beam waist and divergence compare to the ideal Gaussian beam at the same wavelength.

Laser theory teaches us that by design, most laser beam should have a Gaussian beam shape. The fundamental mode of the Gaussian beam (TEM00) is an ideal that most laser system designers want to achieve for three main reasons:

The beam parameter product (BPP) is one laser beam quality indicator that certain people use, and it is defined as the product of the beam’s smallest radius (the beam waist radius, w0) with the beam’s divergence half-angle (θ), measured at the far field. Units of measurement for BPP are mm-mrad:

Gaussian beamcalculator

Apr 28, 2024 — An IR blaster is a device that allows you to control other electronic devices using infrared light. This technology has been around for a while ...

As you can see in the equation above, laser beams with a lower value of M2 can be focused more tightly than lasers with a high M2.

The first lasers were made in the 60s, but it wasn’t until the early 90s that Anthony E. Siegman proposed a standard measurement for how close a laser beam is to this ideal Gaussian beam or, in other words, the measurement of laser beam quality.

Gaussian beamOptics

In the moving stage case, setting up your system and automation routine can take a while, so you can save a lot of time and effort, because we did it all for you already! Our Beamage-M2 automated laser beam quality measurement system goes a few steps further than what was described above and it is so easy to set up that you can start measuring M2 values in a few minutes the first time, and in less than a minute once you get it going.

Numerical aperture (NA) refers to the cone of light that is made from a focusing lens and describes the light gathering capability of the lens (similar to ...

Edmund Scientific Company Star and Satellite Path Finder: Instruction Manual and a great selection of related books, art and collectibles available now at ...

Beam quality measurement will also allow you to know how your laser beam will diverge. When you know your beam’s divergence, you can predict the size of your laser beam at pretty much any point in space. The beam radius for a real beam is defined as:

May 2, 2024 — Refraction is the bending of light when passing through different mediums while diffraction occurs when light waves bend around obstacles or ...

Once the M2 factor is defined, it is possible to inject it back into the equations for generalized Gaussian beam propagation. When you know your laser’s M2 factor, these equations describe how your REAL laser beam propagates, how tightly it can be focused and how quickly it diverges.

Oct 26, 2007 — Just a heads up on this so called hot rod shop or businessman Bill Metz.Quality is garbage,the communication is crap.

by E Lin · 2009 · Cited by 357 — The primary way to increase contrast resolution on CT is to administer intravenous iodinated contrast. With the administration of iodinated contrast, contrast ...

We offer the highest level of technical support that is un-paralleled by any other Electronics Company, with telephone support provided on a 24-7 basis at no cost to our customers, free software updates and in most cases additional features added at no cost to you the requesting client.Laser Electronics Ltd also offers a full Service and Repair facility for all your application needs. We have in-house facilities for the refurbishment of most makes of ion lasers, we repair and service most makes of DPSS and OPSSL lasers, our services also include replacement Brewster windows, cathodes, re-gassing, LBO, KTP, BBO, PPLN and the replacement where necessary of associated optical and electronic components within the laser systems being serviced. We have the expertise to take any Non Working Laser system and resurrect it back to original or better specification.

Ms.Cici

Ms.Cici

8618319014500

8618319014500