Pocket LED Hand-Held Microscopes - portable microscope

The MTC (Micro Turning Center) series of machines was designed according to the needs of ultra-precision turning. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, metals and plastics. Thus, in combination with the C-axis (option), allowing for the turning of nonrotationally symmetric / free-form workpieces (Slow Tool).

Single pointdiamond turning machine

Besides many other accessories, that make the MTC series an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs.

Diamond turningoptics

An optional tool setting camera can be mounted to the main spindle housing, using an industrial pallet system for the connection, to allow for an easy and accurate remounting. Tool holders and a mechanical interface for the in process camera, as well as different measuring devices like 3D-touchprobes or LVDTs can be mounted to the Z-slide.

Besides many other accessories, that make the MTC 250 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

The MTC 350 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. In addition to the X- and Z-axis there is the option to have an additional linear axis. This A-axis allows to do micro milling or raster flycutting operations on the machine.

The travelling distances of the X- and Z-axis are 250 mm and provide the machining of workpieces up to 500 mm in diameter.

Diamond turning machineparts

Besides many other accessories, that make the MTC 250 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

The travelling distances of the X- and Z-axis are 350 mm and provide the machining of workpieces up to 700 mm in diameter.

Diamond turning machineprice

Diamond turning machinereviews

The travelling distances of the X- and Z-axis are 400 mm and provide the machining of workpieces up to 800 mm in diameter.

Diamond turningprocess

The ultraprecision turning machine (UP-Turning machine) MTC 650 is currently our largest series machine. Our customers can machine workpieces up to 200 kg in UP quality.

Besides many other accessories, that make the MTC 650 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

LT Ultra-Precision Technology GmbH Aftholderberg, Wiesenstrasse 9 D-88634 Herdwangen-Schönach Tel.: +49 (0) 75 52 – 4 05 99 0 Fax: +49 (0) 75 52 – 4 05 99 50

The MTC 6500 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Different vacuum chucks for workpieces of up to 800 mm (31.5’’) in diameter are available.

The ultraprecision turning machine (UP-Turning machine) MTC 250 (Micro Turning Center) has a lightweight construction of the moving parts and thus enables the machine axes to be used in a dynamic mode (Slow Tool). This machine is our standard machine with the smallest footprint.

Diamond turning machinemanufacturers

The MTC 250 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide.

When using the rotary table (option), its faceplate is used to mount all the tooling and measurement equipment, offering additional capabilities to the system, such as using the B-axis as a tool turret. The rotary table can also be used to keep a constant cutting point on the tool (3-axis machining, Single Point Turning). Furthermore, the rotary B-axis can be used to selectively change the cutting point if the tool is worn out.

Yes, I have read the privacy policy and I hereby agree that my voluntarily provided data will be permanently stored for contact and for further inquiries. I have the right to delete my personal data at any time.

Diamond turning machinefor sale

Besides many other accessories, that make the MTC 350 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

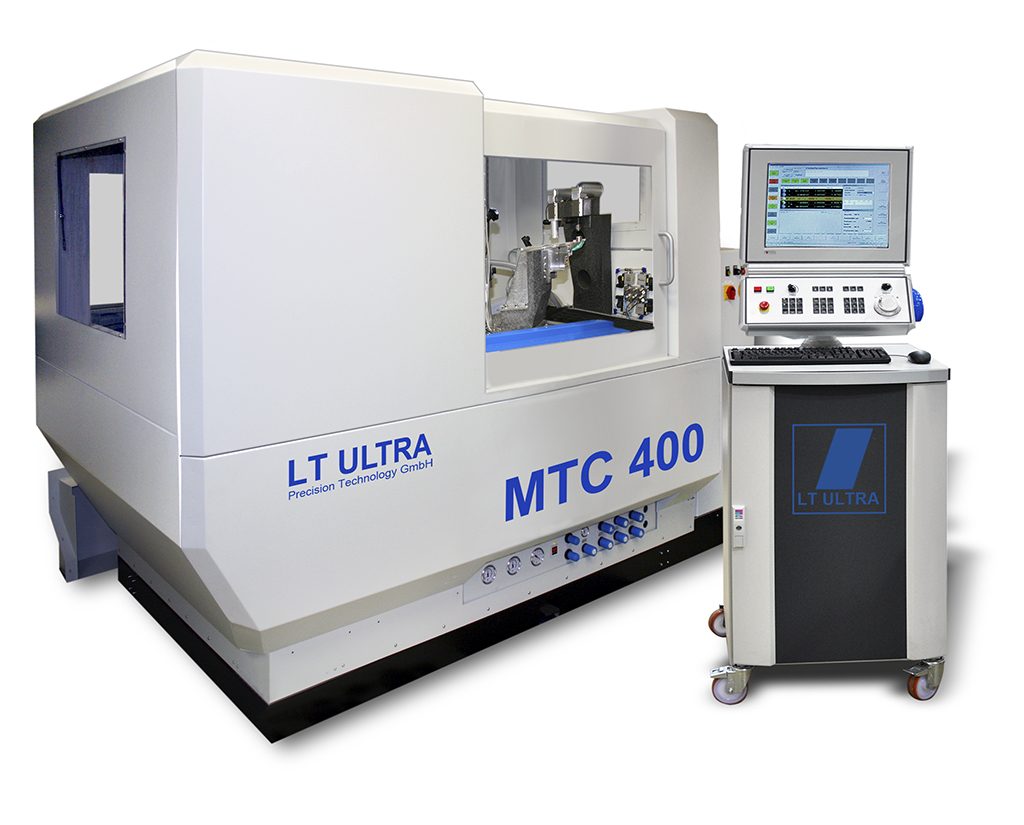

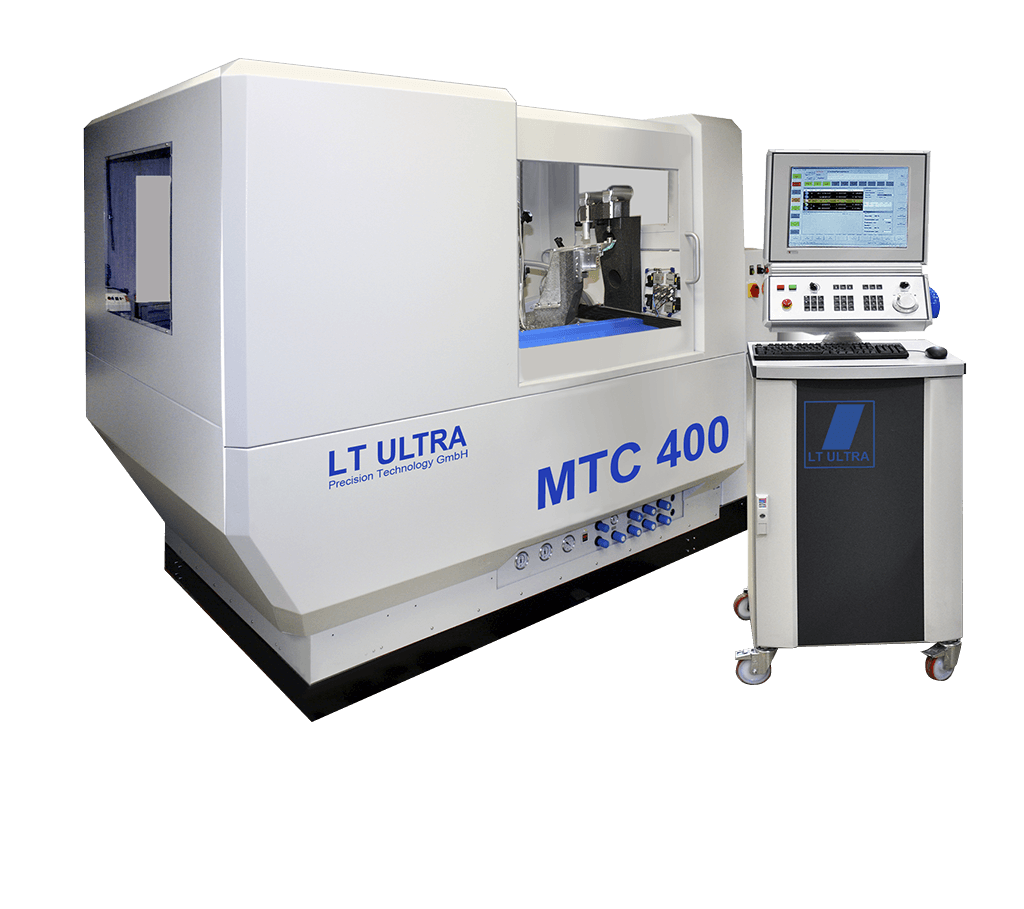

The ultraprecision turning machine (UP-Turning machine) MTC 400 (Micro Turning Center) is designed to hold heavy weight workpieces up to 100 kg.

The travelling distances are 400 mm in the Z-axis and 650 mm in the X-axis. Workpieces with a diameter of up to 800 mm in diameter (optionally 1000 mm) can be machined. The extended X travel offers more space for additional accessories, further tool holders or special bodies/ constructions.

The MTC 400 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Different vacuum chucks for workpieces of up to 800 mm (31.5’’) in diameter are available.

The ultraprecision turning machine (UP-Turning machine) MTC 350 (Micro Turning Center) combines dynamic use with an increased work space, thus resulting in a wide range of products to be manufactured.

Ms.Cici

Ms.Cici

8618319014500

8618319014500