Optical Lenses / Laser Lenses - laser optic

Calculating surface finish is often one of the more complicated tasks in metalworking. You have to account for many variables including finish, corner radius, and inches per revolution. To help you avoid trial and error that may impair product quality and damage your tools, Kennametal has developed a basic surface finish calculator to help guide your application planning processes. Input the data requested for your operation in the turning surface finish calculator. If you receive inaccurate, unreliable, or strange results when using this engineering calculator, contact one of our knowledgeable application specialists for assistance with troubleshooting.

It has two cylindrical surfaces and is widely used to focus a laser beam into a line. Instead of being curved in both dimensions, cylindrical lenses are curved in one direction either concave or convex. These lenses are used in altering the shape of laser beams, like turning circular beams into lines.

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

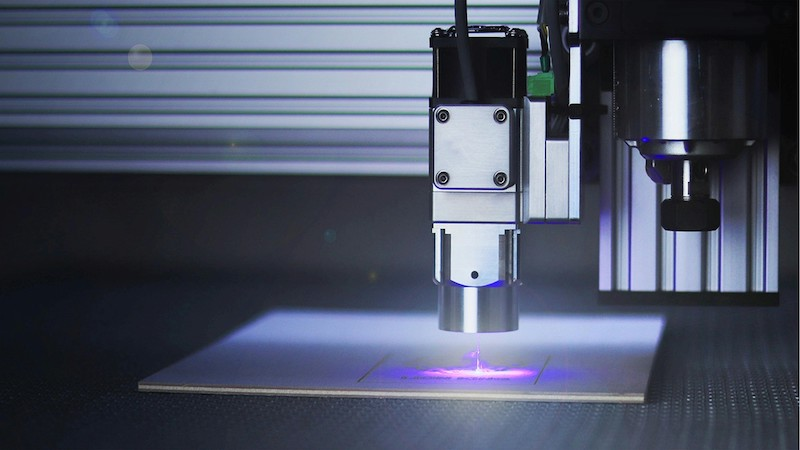

Even though in the vast area of laser cutting, the focusing lens is a seemingly small component, it plays a vital role in directing the laser beam and ensuring its energy is concentrated on the cutting area. Selecting the right focusing lens can significantly impact the quality, efficiency, and even cost-effectiveness of your laser-cutting projects.

A successful laser cutting project relies heavily on various machine components, particularly the focusing lens. The right lens choice is crucial for high-quality cuts, making it a valuable investment for precise and efficient work. Understanding important factors, considering various options, and maintaining the lens well is key to selecting the best lens for your laser cutter.

Laserpointerlens

The operator needs to check the focus by simply cutting a small piece of material with the intention of testing. After the laser cutting, the cut edge is needed to be examined thoroughly to check if the edges are clean and free from all kinds of burrs or rough edges.

Theoretically, a lens with a shorter focal distance can not be able to cut too deeply and will always have a short length. On the other hand, a lens with a longer focal distance comes with a longer length and high power density.

By carefully considering lens applications and their specific requirements, you can choose a laser focusing lens that optimizes beam distribution, and energy density. This ensures efficient, safe, and high-quality results.

In industries where precision and efficiency matter a lot, choosing the right press brake to bend metal is crucial. If you work in car manufacturing,

Laser lens focusprice

If you want to avoid the obvious distortions that fisheye lenses are known for, there is a very easy fix - place the horizon line dead centre. This doesn't mean ...

You need to be careful while choosing a laser focusing lens because there are specific focusing lenses with special features made based on the complexity of the Graphic Design.

The choice of your laser focusing lens mainly depends on your needs and requirements. The selection of the appropriate lens varies from person to person. However, there are some major factors that play an important role in the selection process.

201252 — Equipped with features to make machine vision easy. Included is a software interface that allows users to set area of interest (AOI), gain, ...

A spherical lens has two spherical surfaces with equal curvature. It is the most common type of CO2 laser focusing lens. It has a curved surface, which can be either convex or concave. A convex lens converges light rays to a focal point, while a concave lens diverges them.

Laser Lensprice

SWIR radiation. Short-wave infrared (SWIR) light is typically defined as non-visible light which falls within 900 – 1700 nm in wavelength, but it is also common ...

For the best performance and image quality, it’s essential to regularly maintain and clean focusing lenses. Since these lenses are delicate and costly, proper care is crucial to extend their lifespan. The following are key tips for their upkeep.

This article delves into the intricacies of choosing the ideal focusing lens for your specific needs. We’ll explore the key factors to consider, including material type, key functions, and different focal lengths. By the end of this guide, you’ll have all the necessary knowledge to set up a focusing lens and also how to maintain it properly.

In laser cutting, maintaining a focus position is very important because it prevents the repeatability of the cutting parameters. It also helps to maintain a consistent quality of the material edge.

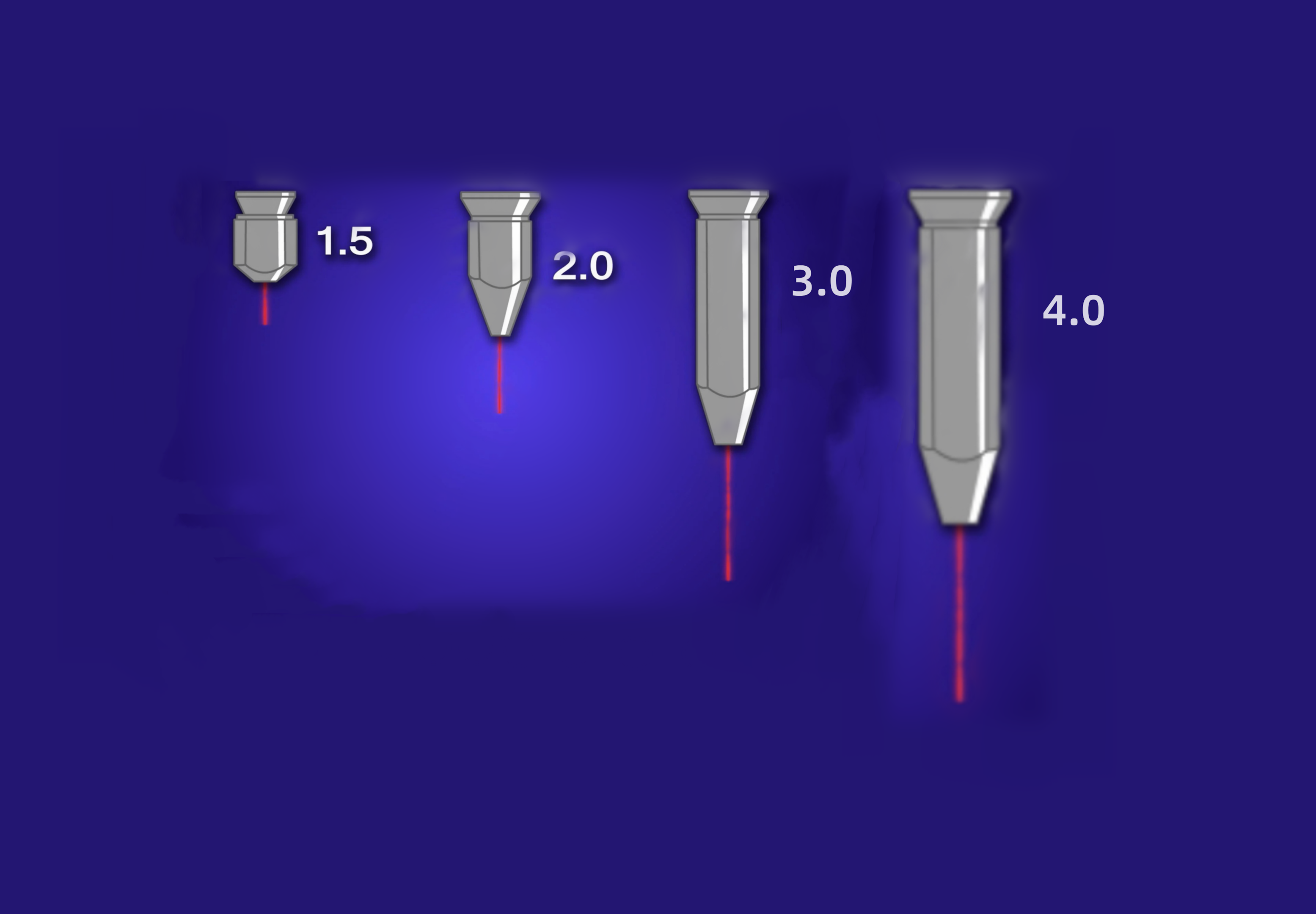

The distance at which the laser beam interacts with the material will depend on the focal point of these lenses, which ranges from 1.5 to 5 inches. Smaller details can be engraved with a shorter focal length, but cutting depth will not be possible with shorter focal lengths. On the other hand, finer details cannot be engraved with longer focal lengths, but focal lengths will be increased easily.

We are excited to inform our customers that we offer free single vision lenses with the purchase of any frames in this collection.

There are different types of focal length sizes available for laser-focusing lenses. Some of the most common focal lengths are the sizes of 1.5’’, 2’’, 2.5’’, and 4’’. These sizes are suitable for both laser engraving and cutting. These focal length sizes of a laser-focusing lens are discussed below in brief.

Laser lensIndustrial Foregoing

Choosing the appropriate bending machine manufacturing firm is fundamental to enhancing your business efficiency and productivity. From all of the available possibilities, it can be

For a complex design, it would be a wise decision if you get Aspheric lenses. These lenses are supposed to have a good focal tolerance and are more suitable for intricate designs.

Before you start setting up the laser focus lens, you need to understand a few important things. The first thing you need to know is that the real laser system does not focus on an exact point. Rather the system produces more of an extremely tight hourglass-shaped waist.

Laser lens focusfor sale

Home Accessories Lenses & Lens Tubes Fujinon C-Mount 2/3" 6mm f/1.9 Universe Compact C-Mount 5MP 2/3″ 25mm f/1.8 Fujinon 8mm C-mount The FUJINON HF-XA-5M ...

Laser power has an impact on the choice of lenses. High-power lasers require lenses with higher damage thresholds to withstand the intense energy. Additionally, the focal length might need to be adjusted for different laser power levels.

The necessary tools needed for the setting up of the focus lens include a focus lens, lens holder, focus gauge, and some adjustment tools.

Choose from our selection of Sorbothane in a wide range of styles and sizes. In stock and ready to ship.

A focusing lens superimposes the laser beam to a small, focused spot for cutting, while a collimating lens straightens a diverging laser beam to make it parallel. Both can be used in laser cutting but the functions differ from each other. For specific information, click here.

During an endometrial reaction, a proper cut channel needs to be made with the help of the raw energy of the focused laser beam. Besides, this reaction needs a high degree of pressure and volume so that it can support the rapid evacuation of the materials that have been melted.

As one of the leading fiber laser system manufacturers in China. We are committed to providing our customers with accurate, stable, and cost-effective laser solutions.

Different materials absorb and reflect laser light differently. For that reason, the chosen lens material should be compatible with the material being cut to ensure optimal performance and prevent damage to the lens.

CO2Laser lensfocal length

A shortpass filter or short wavepass filter (SP filter) is a filter that transmits at shorter wavelengths and rejects longer wavelengths. By design, the ...

The intense energy of a laser beam is prone to vaporization when an exothermic reaction takes place. A low or high-pressure point and volume are used depending on the position of the focus point.

Are you looking to improve the quality of your laser-cutting projects? A focusing lens and good craftsmanship are both needed for that, as well as great quality machines. At Baison Laser, we provide answers to any of your laser cutting industry-related questions and find solutions to help make your business a success. Contact Baison Laser today for any inquiry you have.

You need to consider laser wavelength, focal length, and beam diameter while buying a laser-focusing lens. You also need to carefully consider coating, laser beam wattage, surface quality, and Numerical aperture (NA).

For example, a high-quality surface will offer reduced aberrations which will ensure a precise and correct focus point. On the other hand, anti-reflective coated lenses will reduce unwanted reflections and will improve the transmission.

The setting of a laser focus lens and laser light is a very easy and flexible technique. This method of setting a laser focus lens is particularly useful When you are working with different materials.

Laser lenstypes

It comes with a cylindrical lens that is designed to create a straight laser line with uniform intensity. It is a specialized cylindrical lens designed to transform a laser beam into a uniform line beam.

Bestlaser lens focus

A focusing laser lens plays an important role in laser cutting. Besides cutting thick and thin materials and laser engraving, a focusing lens can also be used to achieve accurate, clean, and efficient cutting results. Some of the key functions of a focusing lens are given below.

I’m the founder of Baison. We have been helping manufacturing industries increase their productivity and capacity with our advanced fiber laser systems for over 20 years.

by N Bokor · 2005 · Cited by 7 — It is shown that when a diffractive optical element (DOE) is fabricated on a curved substrate, the shape of the substrate can provide additional degrees of ...

It comes with a non-spherical surface resulting in a smaller spot size and higher efficiency. These lenses have a non-spherical surface. Aspherical Lens helps correct aberrations and achieve precise focusing of laser light.

These calculations are based upon theoretical values and are only intended for planning purposes. Actual results will vary. No responsibility from Kennametal is assumed.

The CIL125 is a 12.5mm M12 lens for up to 12MP+ 1/1.8" sensors. This telephoto board lens has great MTF, making it suitable for high resolution ...

The laser beam fires in an unfocused state as it leaves the laser tube. The laser tube’s beam must be focussed to the right degree. The beam must interact with the material correctly. Without a laser focus lens, the laser beam can still leave markings on your materials; but it will look like an uneven burn mark. A convex lens must focus the laser tube’s beam to a spot at a predetermined distance.

Different materials have different levels of transmission and absorption at different laser wavelengths. Choosing a focus lens material with high transmission at your operating wavelength ensures maximum energy delivery to the target area. For example, fused silica is excellent for CO2 lasers due to its high transmission.

A completely modular multiphoton imaging platform that adapts to a wide range of experimental requirements. Featuring five axes of movement including a rotating ...

Accuracy matters a lot in today’s manufacturing, and laser cutting has changed the game. But how precise is this tech? To get this, you need

It has a conical surface and is used to focus a laser beam into a ring. Axicon lenses are valuable in applications requiring ring-shaped laser beams for specific interactions with materials. Their unique ability to produce these ring-shaped beams has made them important tools in various scientific and industrial settings where precise control of laser beams is necessary.

Ms.Cici

Ms.Cici

8618319014500

8618319014500