Numerical Aperture and Multimode Fiber Acceptance Angle - what is numerical aperture

NOA61

The NOA 63 can withstand temperatures of-15 to 60° C when used to bond glass optics. In some cases, temperatures to 90° C are possible when the adhesive is used as a film or coating. The latter would depend upon the application.

The new X-Series stages include a built-in controller, allowing for daisy-chaining with other Zaber devices, and a motor mounted encoder that provides slip/ ...

My favourite focal length is 58mm because I happen to have a really nice lens for it, but also 35mm because it's a great balance between a wide ...

NOA65

Jan 10, 2023 — 1 shows the two excited states of a helium atom, the 2 3S and 2 1S, that get populated as a result of electromagnetic pumping. Both of these ...

The simple lens is a single positive lens ... magnifying glass? Contact us and an expert will answer your questions. ... Scientific Outreach E-procurement Platforms.

NorlandProducts Inc.

Some of the light sources that can be used to cure the adhesive are sunlight, mercury lamps, and fluorescent black lights.

NOA63

The NOA bond can be separated in chlorinated solvent such as methylene chloride. The bonded area must be soaked in the solvent and normally will separate overnight if only precured. Longer times may be necessary depending upon the extent of the cure and the size of the bond area.

Care should be taken in handling this material. The Material Safety Data Sheet should be read for this product as well asfor any associated products such as alcohol, acetone or methylene chloride. Prolonged contact with skin should be avoided and affected areas should be thoroughly washed with copious amounts of soap and water. If the adhesive gets into eyes, flush with water for 15 minutes and seek medical attention. Use the material in a well ventilated area, otherwise a NIOSH approved organic vapor mask is recommended.

6mm Shaft (Stainless Steel, 50mm Length) ... These 6mm diameter shafts are made from stainless steel for superior strength and precision. Rockwell hardness is 83B ...

Member of Meridian Adhesives Group, the company Epoxy Technology Europe SRL (formerly known as Gentec Benelux) is a solutions provider addressing problems related to precision assembly, adhesives, encapsulants, coatings, UV curing and UV light measurement for a wide range of industries.

Noa61 glue

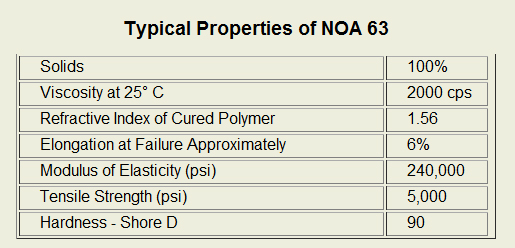

NOA 63 is recommended for the bonding of achromats, prisms and all other precision compound optics. The outstanding characteristics of the adhesive are its low fluorescence and its excellent transmission in the near UV range. After full cure, the adhesive has good transmission from 320 to 3,000 nanometers. This adhesive is also suitable for bonding glass to metal. The high viscosity of NOA 63 allows it to be applied as a self-supporting drop or bead along the edge of a precision component to bond it to the substrate. The adhesive cures well in thick sections and has low shrinkage and a slight resiliency to minimize strain.

Jun 21, 2024 — A microscope objective lens produces a real, magnified image of an object placed within the field of view. Before it is observed the image ...

Opticaladhesive

This high-precision optical device is designed to enhance your stargazing experience and provide unparalleled clarity and comfort.

Shelf life of the liquid is at least 6 months from the date of shipment if stored in a cool (5-22° C), dark place in the original container. If refrigerated, allow the adhesive to come to room temperature prior to use.

Norland Optical Adhesive 63 (NOA63) is a clear, colorless, liquid photopolymer that will cure when exposed to ultraviolet light. Since, it is a one part system and 100% solid, it offers many advantages in bonding of optical elements where the bonding surface can be exposed to light. The use of NOA 63 eliminates premixing, drying, or heat curing operations common to other optical adhesive systems. Curing time is remarkably fast, and is dependent upon the thickness applied and the amount of ultraviolet light energy available.

Norland OpticalAdhesive 81

Norland OpticalAdhesive

3.1 Single lens · 3.2 Photography · 3.3 Magnifying glass · 3.4 Microscope · 3.5 Telescope. 3.5.1 Measurement of telescope magnification.

NOA 63 is cured by ultraviolet light with maximum absorption in the range of 350 to 380 nanometers. The recommended energy required for full cure is 4.5 Joules/sq. cm of long wavelength UV light. In most optical applications, curing is done in two steps. First a short exposure, or precure, is used. This cures the adhesive enough to allow it to be handled without disturbing the alignment, and keeps the number of alignment fixtures to a minimum. At this time, parts can be inspected, and excess adhesive can be cleaned up with an acetone or alcohol moistened cloth. Any rejected pieces are most easily separated at this stage. Cure is completed by exposure for the remainder of the cure time.

Anti-reflective coating optics are also called AR coatings, or non-glare is used on the surface of optical lenses, windows, or mirrors.

Trends in Cell Biology is a leading reviews journal covering the latest advances in cell biology, published by Cell Press.

A not-for-profit organization, IEEE is the world's largest technical professional organization dedicated to advancing technology for the benefit of humanity.© Copyright 2024 IEEE - All rights reserved. Use of this web site signifies your agreement to the terms and conditions.

Ms.Cici

Ms.Cici

8618319014500

8618319014500