MTF curves and Image appearance - lens mtf measurement

Single sided plano optics are ground and polished on one side only. These flats are frequently used as “test plates,” or reference surfaces, to which the flatness of other optics or substrates is compared. Plano references are typically made from extremely stable materials such as fused silica, BK7 glass, Zerodur, Zinc Sulfide, Germanium, Sapphire, Silicon or Zinc selenide. A single sided optic may also serve as the substrate for a high-quality optical mirror.

NanoCam HD systems measure surface roughness on coated and uncoated plano optics to ensure the quality of polishing processes.

When you correct distortion in a photo, the edges of the photo may bulge outwards or shrink inwards. Use the Background color options to fill gaps in the corners or sides of a corrected photo:

NanoCam HD systems measure surface roughness on coated and uncoated precision surfaces to ensure the quality of polishing processes.

Beam Expanders allow a standard AccuFiz system to measure optics with diameters up to 800mm, including solid state laser optics and high energy laser amplifier slabs.

Select this option if you want to display a grid over the photo while you correct distortion. This is useful if you want to assess whether objects in the photo are straight.

Spatial inhomogeneity of an optic’s refractive index can be caused by the melting process, by variations in density or by permanent stresses due to temperature gradients during cooling.

In the most general sense, plano optics include all components with a surface that can be tested using a collimated beam to compare it against a flat reference. By that broader definition, the family of plano optics can be said to also include beam splitters, corner cubes, prisms, periscopes, etalons for spectroscopy, etc.

This tech note explains the purpose of the Wedge Factor and its correct values for measuring wavefront error and surface height in common testing configurations.

OpticalFlatfilter

Dual sided plano optics, or double-sided plano optics, are polished to specification on both sides. A double-sided optic may be used as an optical window (with two parallel surfaces), a wedge (with the two surfaces polished at a small angle relative to each other), as a substrate for an optical filter, as a material sample to test homogeneity, or as a reference for evaluating another test optic.

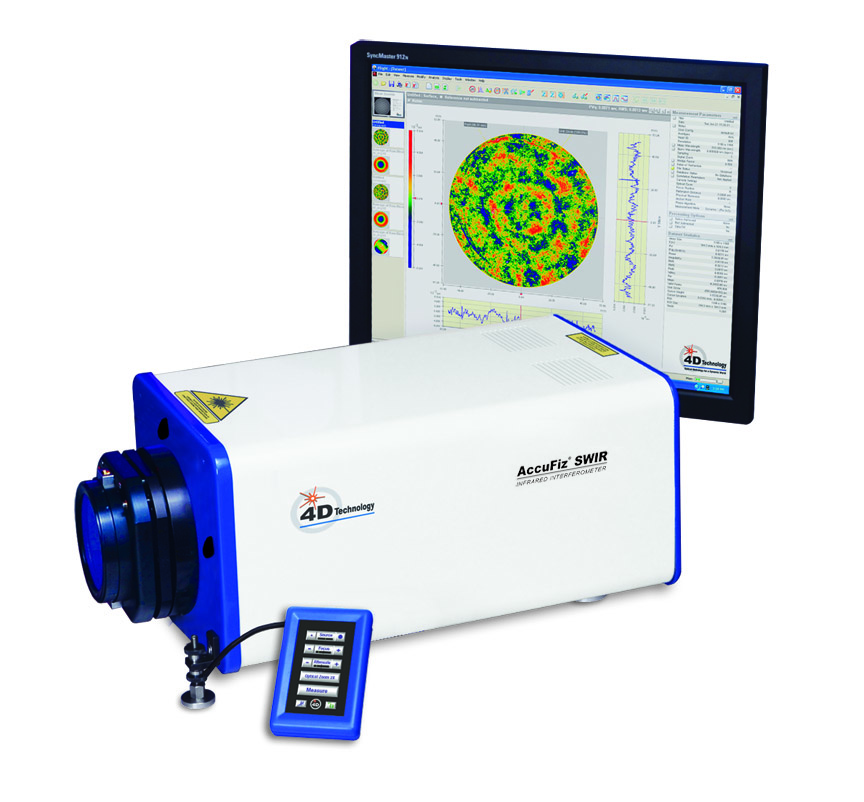

Excels at fast, repeatable measurement of surface shape and transmitted wavefront error of flat and wedged optics. It is the most versatile Fizeau available, for any production environment.

Flatoptics with designer metasurfaces

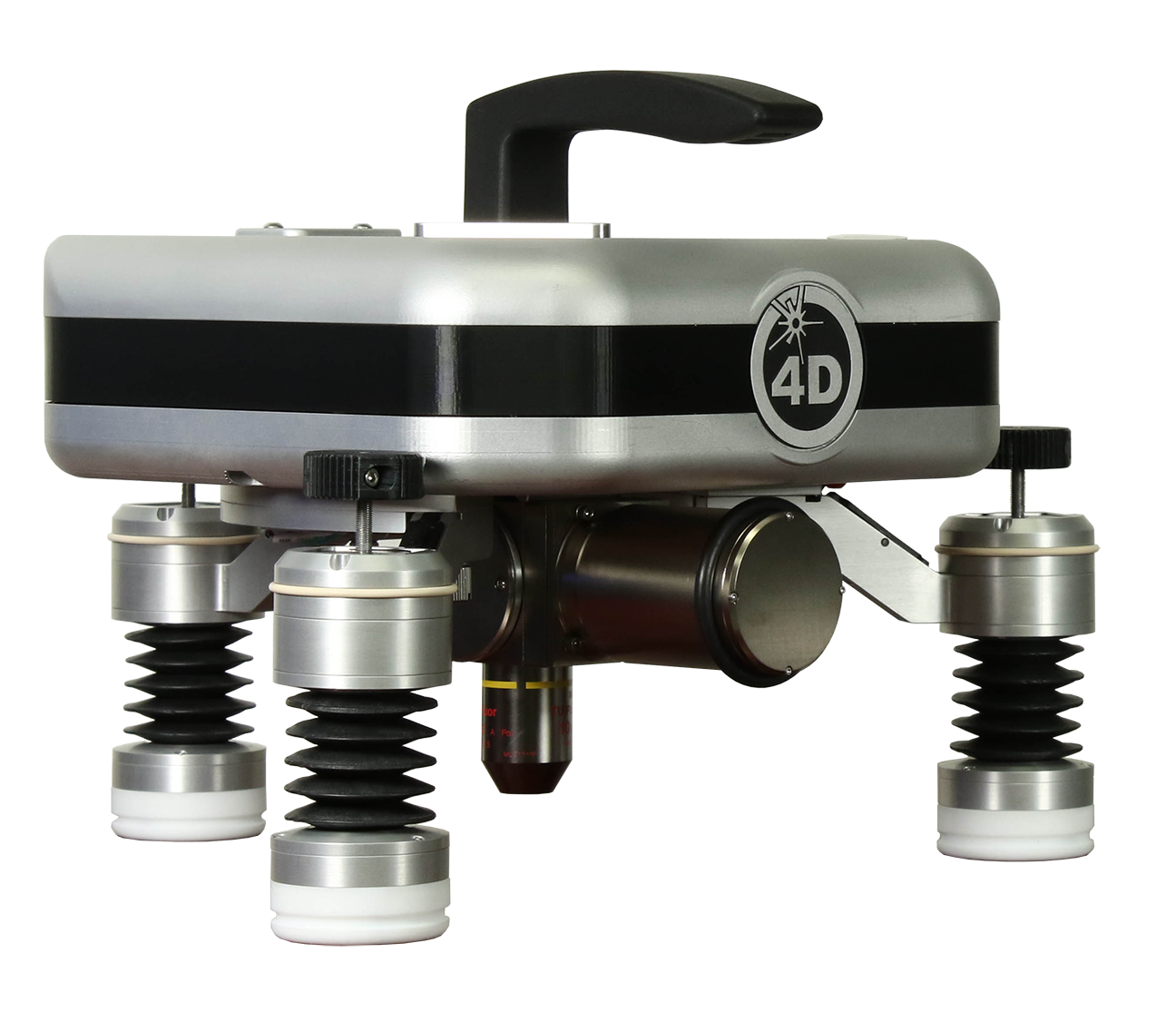

Measures both sides of transparent, parallel optics as thin as 200 microns, surfaces in multi-surface optical systems, remote cavity test setups, and solid cavities such as etalons (laser rods).

Click Reset to clear your changes and reset to default settings. If you saved your changes, you cannot reset your settings. If you want to discard only the Edit settings, select File | Restore to Developed.

4D’s Fizeau laser interferometers measure flatness, shape, thickness uniformity, homogeneity and wedge of plano optics, mirrors, windows, wedges, wafers, filters, etc. 4D Fizeau systems are available to measure flat optics at wavelengths from deep UV through IR.

Opticalflat

You can use the Lens Distortion Correction tool to correct barrel, pincushion, and fisheye distortion in digital photographs. In barrel distortion the photo appears to bulge outwards from the center. In pincushion distortion the photo appears to shrink inwards toward the center. In fisheye distortion, the photo appears to bulge outwards from the center, as if the photo were wrapped around a sphere.

The compact AccuFiz Fizeau excels at fast, repeatable measurement of surface shape and transmitted wavefront error of flat and wedged optics. With the optional Surface Isolation Source (SIS) the AccuFiz can measure both sides of transparent, parallel optics as thin as 200 microns, as well as surfaces in multi-surface optical systems, remote cavity test setups, and solid cavities.

Ms.Cici

Ms.Cici

8618319014500

8618319014500