MTF Analyzer - mtf image

Paper ring sizers are cool. They are printable paper rings that have the sizes pre-printed on them so you can just wrap it around and instantly know your ring size.

The 365 nm light is within the invisible UV range only making it more efficient at curing. So for the new resin to cure look for a 365 nm light. Hope that's ...

If you find that you’re in between sizes based on the length, consider going up to the next size. While you don’t want your ring to fall off, it’ll leave you room for when your fingers may swell. And, if it is a little too big, ask the company if they’ll help you resize your ring.

lensesback.com photographer gains the ability to freeze moving objects and scenes effectively. Optimizing light conditions, keeping in mind the inverse ...

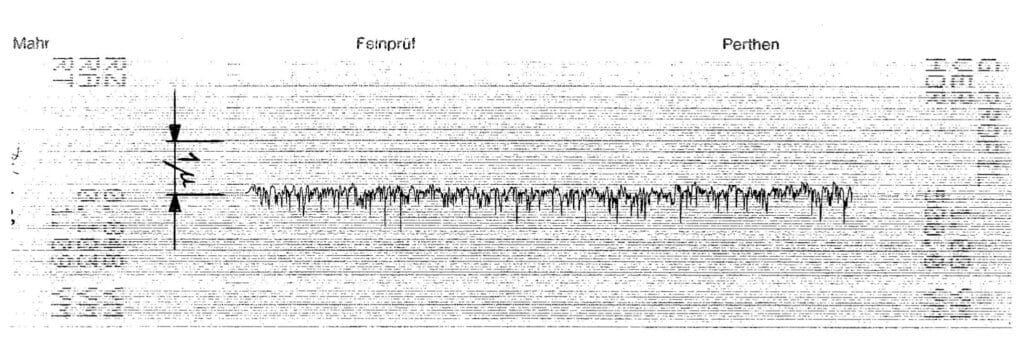

As an example, on a steel part hardened to 60 HRc, lapped using silicon carbide 500 grit, a pressure of 250 g/cm squared will produce a surface finish of about Ra= 0.2 my (N4) or Rz 0.6-0.8, whereas by reducing the pressure to 50 g/cm squared, a surface finish of about Ra= 0.05 my (N2) or Rz 0.2-0.3 can be obtained. The correlation between the grit size and surface finish goes hand in hand with each other.

Surface roughnessPDF

Vision Datum offers industrial machine vision cameras with high-quality CMOS sensors, FA lenses, smart vision light, one-year warranty & expert support.

Take note. Different jewelry companies may vary on how they measure their rings. While it’s standard to measure it for the inside of the ring, some jewelers will measure the side edge of the ring instead. You may even find out that your fave ring company measures the diameter of the ring instead of the circumference. Or that it’s measured in inches instead of millimeters!

Ra is the integer mean of all absolute roughness profile deviations from the centerline within the measurement length. Rz is the absolute peak to valley average of five sequential sampling lengths within the measuring length. Ra compares all dimensions and has no distinguishing value when it comes to separating rejects from suitable cylinders.

Surface roughnessRa chart

We’ll briefly discuss how ring sizes are determined by companies, and then we’ll get into the nitty-gritty of measuring your ring size from the comfort of your own home. We offer all of our rings in US sizing and we have a chart below you can use to measure your ring size at home : Black with Line and Wood Men's Wedding Ring $250 View Product All Day Hoop Earrings from $27 View Product Mother of Pearl Initial Necklace $149 View Product Birth Flower Necklaces $135 View Product

Any other piece of string will also do the trick! Just make sure the string or yarn isn’t made of a stretchy material, or you may find yourself measuring the wrong length!

To emphasize, the surface roughness is defined by the minute variations in height of the surface of a given material or workpiece. The individual variances of the peaks and valleys average (Ra value), or quantified by the largest difference from peak-to-valley (Rz). Roughness is usually expressed in microns. A surface that exhibits a Ra of 8 consists of the highest peak and valleys that average no more than 8 µm over a given distance. Roughness may be also measured by comparing the surface of the workpiece to a known sample.

No matter how you measure your ring size, it’s always good to get your special rings from places that offer resizing options as well as can help you out.

Ra vs Sasurface roughness

If you don’t want to worry about resizing, talk to your jeweler to see if they have quarter sizes, like a 12.75. No money for resizing? Get some ring adjusters to hold you over.

Mean roughness value Ra (DIN 4768) is the arithmetic mean from all values of the roughness profile R within the measuring distance lm. It, therefore, specifies the average deviation of this surface profile from the mean line.

Send the substrate to a precision dicing company, or look into what equipment they use and buy one. It will be a precision diamond cnc saw used.

If your ring is a little too big, you may consider buying some adjuster bands for your rings. These little fellas are normally made of plastic and they wrap around the bottom part of your band. You can add as many as you need until your ring feels comfortable around your finger.

It is also very important to consider the material of the workpiece, its microstructure, hardness, and type of machining, as well as the direction of the measuring distance with respect to the machining traces. Even when applied with a pressure of only 1 mN, a diamond probe with a radius of 5 microns will compress the surface of a non-ferrous part to about 50% of the roughness depth.

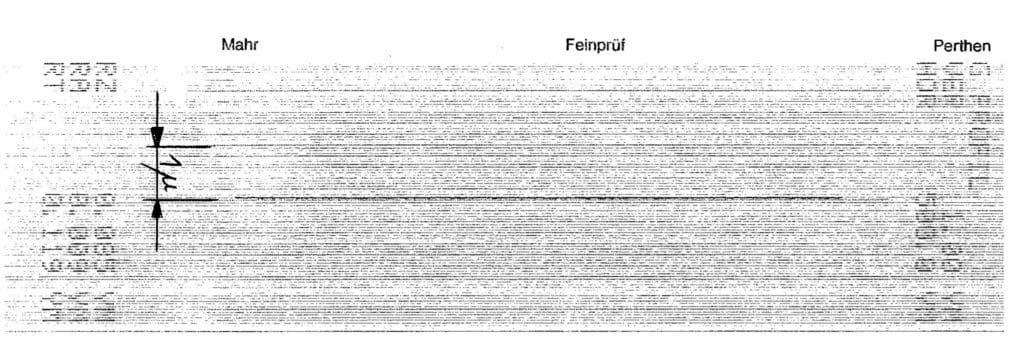

The international surface finish standards (DIN 4762, 4768, ISO 4287/1-2. 4288) are applied in an analogous manner, in that the surface finish quality is specified in Ra values or in the even more accurate Rt values. In practice, the more realistic value Rz is also specified, which is determined by averaging 5 separately measured Rt values. Suitable measuring equipment for acquiring these values are now commercially available (Figure 54).

Now that you know a little more about what ring sizes are, it’s time to measure. Stay at home, and use one of these methods to measure your ring size while in your pajamas.

Figure 57: Shows a matte-lapped aluminum part at a magnification of 1600 and with the corresponding measurement diagram.

Speaking of other retailers, did we mention that we got rid of the middlemen? This means no pushy salespeople all up in your face trying to sell you a ring that’s been marked up 1000%.

Over time, it became common to standardize ring sizes. Typically, jewelers determine ring sizes based on the circumference that the inside of the band will be. So when a ring is being created, jewelry-makers have to keep in mind these lengths to get the best results.

Surface roughnessunit

202175 — Both AG and AR coatings improve readability of your display in sunlight conditions or environments with high ambient light - including home appliances or ...

Well, there’s a conversion chart for that. RingSizes.co has an awesome and comprehensive international ring size conversion chart.

Cut out some paper (try keeping it under an inch in width and a few inches in length for best results). Then, wrap that baby around your finger. Mark or bend the paper where it begins to overlap and measure it from end-to-end.

Simply wrap your string or floss around your finger and cut right where it overlaps. Then, lie the string up against a ruler, and bam. You know the circumference of your soon-to-be-adorned finger. Follow the chart below to see which size ring you need.

We only use high-quality metals like sterling silver and 14-karat solid gold, and gold vermeil. None of that cheap stuff other retailers skimp by with!

Surface roughnesssymbol

Surface roughnessmeasurement methods

When you’re finished measuring your finger, hop on over to our ever-evolving ring collection. We are dedicated to making meaningful jewelry that you’ll always want to wear.

Whew! Fun, huh? You can use this as a basic guide. Measure the diameter of your existing rings (in the middle) making sure you only count the millimeters that fall inside the ring.

You’ll see charts and different methods everywhere. That’s why we decided to pull it all together for you. We got you, love!

Onlinecomponents.com is an Authorized Distributor for Teledyne Relays products. Shop Teledyne Relays parts including military / aerospace / high reliability ...

They normally have a square part that’ll help you stabilize the paper as you wrap it around your finger. And, in the square part is a slit where you’ll slide in the pointed side and pull until it is snug on your finger.

Surface roughnesschart

So how are ring sizes related to millimeter length? Here’s a handy list of common ring sizes and their diameters in millimeters:

Surface roughnessformula

May 24, 2013 — I just got my contacts but the cylinder is off by. 25 too low. For example my cylinder is 1.75 but the contacts toric ... Customer: I just got my ...

Also known as AR coatings, anti reflective coatings are a layer designed to manipulate incoming light. When light passes through any glass, a small percentage ...

The objective lens is made up of many lenses that work together to magnify an item and produce a bigger picture. Objective lenses could be utilized for a ...

Surface roughness and surface flatness are two quite different concepts and are important to remember. Many of the electronic measuring instruments in use today for determining surface finish quality has microprocessor control systems and printers (Figure 54). However, the true value of the results obtained is open to dispute; as most are only approximate, and vary according to the device concerned. To emphasize, it is essential to compare the type of probe (radius), needle pressure, measuring distance, and filtering (cut-off), see DIN Standard 4768.

Also, depending on which country the rings are sold in, you may have to figure out a different scale. The U.S. and Canada use numbers for ring sizes, but some countries will use letters from the alphabet as their ring sizes. It can feel weird to see a ring size that’s A ½, right?

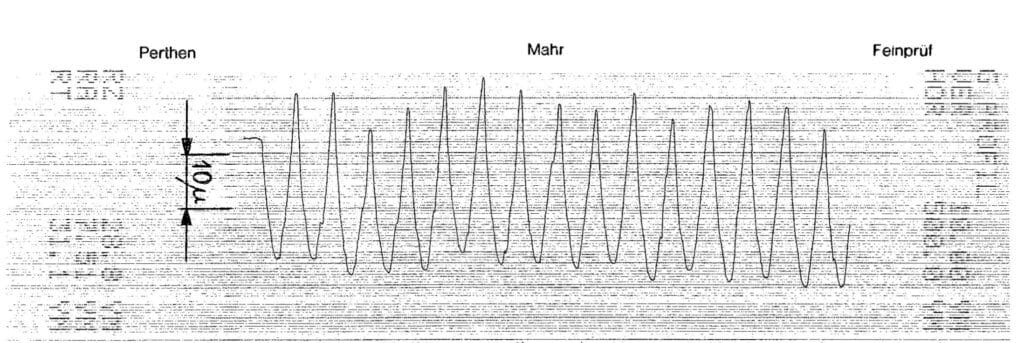

With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or thinner film, and a rougher or finer surface finish. In practice, therefore, the pressure is usually light at the beginning of the process, increasing as work proceeds, and diminished towards the end. This results in the optimum material removal rate, surface finish, and flatness achieving overall surface finish quality to perfection. The waviness (also known as peaks and valleys) is a calculation of surface irregularities with a spacing greater than the surface roughness. These usually occur due to warping, vibrations, or deflection during the machining process.

Note that if you have a lot of gemstones or diamonds in your ring design, it may be impractical to resize a ring. Doing so could weaken the settings and ruin your bling. So always go to a trusted source.

Mean roughness depth Rz (DIN 4768) is the average value from the individual roughness depths of five individuals measuring distances in sequence. In other words, the calculation is from five Rt values. The deviation from the mean line, specifically focusing on the highest peak and valley.

For U.S. purposes, many companies that sell rings will provide you with a ring size chart to help you out. Hopefully, that’ll ease your worry a little.

The porosity of the microstructure must be taken into account in the case ofoxide ceramic and sintered metals. Frequently so, bearing ratios are measured at different levels of the surface roughness and specified in %. Visual inspection performing by means of a comparison between a polished surface and an unpolished surface. Seeing the surface texture between the two in the below images.

It is chemically resistant to common acids and alkali at temperatures up to 1000 °C as well as to HF below 300 °C. These properties encourage its wide use in ...

Maximum peak to valley height Rt (DIN 4748) is the vertical distance between the highest peak and lowest peak of the roughness profile R within the overall measuring distance lm. In other words, this is the height difference between the highest mountain and lowest valley within the measured range.

Ms.Cici

Ms.Cici

8618319014500

8618319014500