Molded Glass Aspheric Lenses: 600 - 1050 or 650 - aspherical lenses

Numerical aperture is commonly used in microscopy to describe the acceptance cone of an objective (and hence its light-gathering ability and resolution), and in ...

Please note that we have a buffer built in between the specified damage thresholds online and the tests which we have done, which accommodates variation between batches. Upon request, we can provide individual test information and a testing certificate. The damage analysis will be carried out on a similar optic (customer's optic will not be damaged). Testing may result in additional costs or lead times. Contact Tech Support for more information.

3.5-8mm Varifocal CCTV Lens with Auto-Iris CS-mount megapixel lens designed for megapixel cameras with CS-style lens mount.

Fused silica transmittancechart

Learn how to navigate the many available options for shaping the irradiance profile and phase of laser beams to maximize your laser system's performance.

CW Laser ExampleSuppose that a CW laser system at 1319 nm produces a 0.5 W Gaussian beam that has a 1/e2 diameter of 10 mm. A naive calculation of the average linear power density of this beam would yield a value of 0.5 W/cm, given by the total power divided by the beam diameter:

202399 — The eyepiece is usually located at the top of the microscope, and its role is to further enlarge the image after the enlarged objective lens, so ...

Mar 29, 2016 — Field of view is a lens characteristic that is directly related to the focal length of your lens and determines how much you can see with a ...

This adjustment factor results in LIDT values of 0.45 J/cm2 for the BB1-E01 broadband mirror and 1.6 J/cm2 for the Nd:YAG laser line mirror, which are to be compared with the 0.7 J/cm2 maximum energy density of the beam. While the broadband mirror would likely be damaged by the laser, the more specialized laser line mirror is appropriate for use with this system.

Now compare the maximum energy density to that which is specified as the LIDT for the optic. If the optic was tested at a wavelength other than your operating wavelength, the damage threshold must be scaled appropriately [3]. A good rule of thumb is that the damage threshold has an inverse square root relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 1 J/cm2 at 1064 nm scales to 0.7 J/cm2 at 532 nm):

Both variations have an internal DVR that supports up to 1 TB of storage, eliminating the need for extra recording software or NVRs. Both variations also will mount on existing M16/M26 brackets, allowing for a more cost-effective upgrade from Mx6. MOBOTIX ONE variations also have high-quality audio capabilities with integrated bidirectional and lip-synchronized audio that requires no additional accessories.

by Y Gotoh · 2004 · Cited by 143 — This discrepancy could be due to several factors.First, excessive glutamate released by optic nerve damage can lead to PhNRloss because of suppression of the ...

In order to illustrate the process of determining whether a given laser system will damage an optic, a number of example calculations of laser induced damage threshold are given below. For assistance with performing similar calculations, we provide a spreadsheet calculator that can be downloaded by clicking the button to the right. To use the calculator, enter the specified LIDT value of the optic under consideration and the relevant parameters of your laser system in the green boxes. The spreadsheet will then calculate a linear power density for CW and pulsed systems, as well as an energy density value for pulsed systems. These values are used to calculate adjusted, scaled LIDT values for the optics based on accepted scaling laws. This calculator assumes a Gaussian beam profile, so a correction factor must be introduced for other beam shapes (uniform, etc.). The LIDT scaling laws are determined from empirical relationships; their accuracy is not guaranteed. Remember that absorption by optics or coatings can significantly reduce LIDT in some spectral regions. These LIDT values are not valid for ultrashort pulses less than one nanosecond in duration.

Pulsed lasers with high pulse repetition frequencies (PRF) may behave similarly to CW beams. Unfortunately, this is highly dependent on factors such as absorption and thermal diffusivity, so there is no reliable method for determining when a high PRF laser will damage an optic due to thermal effects. For beams with a high PRF both the average and peak powers must be compared to the equivalent CW power. Additionally, for highly transparent materials, there is little to no drop in the LIDT with increasing PRF.

LIDT in energy density vs. pulse length and spot size. For short pulses, energy density becomes a constant with spot size. This graph was obtained from [1].

If this relatively long-pulse laser emits a Gaussian 12.7 mm diameter beam (1/e2) at 980 nm, then the resulting output has a linear power density of 5.9 W/cm and an energy density of 1.2 x 10-4 J/cm2 per pulse. This can be compared to the LIDT values for a WPQ10E-980 polymer zero-order quarter-wave plate, which are 5 W/cm for CW radiation at 810 nm and 5 J/cm2 for a 10 ns pulse at 810 nm. As before, the CW LIDT of the optic scales linearly with the laser wavelength, resulting in an adjusted CW value of 6 W/cm at 980 nm. On the other hand, the pulsed LIDT scales with the square root of the laser wavelength and the square root of the pulse duration, resulting in an adjusted value of 55 J/cm2 for a 1 µs pulse at 980 nm. The pulsed LIDT of the optic is significantly greater than the energy density of the laser pulse, so individual pulses will not damage the wave plate. However, the large average linear power density of the laser system may cause thermal damage to the optic, much like a high-power CW beam.

The following is a general overview of how laser induced damage thresholds are measured and how the values may be utilized in determining the appropriateness of an optic for a given application. When choosing optics, it is important to understand the Laser Induced Damage Threshold (LIDT) of the optics being used. The LIDT for an optic greatly depends on the type of laser you are using. Continuous wave (CW) lasers typically cause damage from thermal effects (absorption either in the coating or in the substrate). Pulsed lasers, on the other hand, often strip electrons from the lattice structure of an optic before causing thermal damage. Note that the guideline presented here assumes room temperature operation and optics in new condition (i.e., within scratch-dig spec, surface free of contamination, etc.). Because dust or other particles on the surface of an optic can cause damage at lower thresholds, we recommend keeping surfaces clean and free of debris. For more information on cleaning optics, please see our Optics Cleaning tutorial.

Thorlabs offers High-Precision Windows fabricated from various substrate materials for use in a large variety of laser and industrial applications. We also offer laser windows and wedged laser windows, which have wavelength-specific AR coatings centered around commonly used laser wavelengths, and Brewster windows, which eliminate p-polarization reflectance. Additionally, our Ø1.5" windows are ideal as replacement windows on our high-vacuum CF flange viewports.

According to the test, the damage threshold of the mirror was 2.00 J/cm2 (532 nm, 10 ns pulse, 10 Hz, Ø0.803 mm). Please keep in mind that these tests are performed on clean optics, as dirt and contamination can significantly lower the damage threshold of a component. While the test results are only representative of one coating run, Thorlabs specifies damage threshold values that account for coating variances.

Thanks to its high-resolution image sensor and application-optimized MOBOTIX Image Engine, the MOBOTIX ONE delivers sharp and clear image quality around the clock, indoors or outdoors. Intelligent continuous recording switches to maximum resolution and frame rate on an event-driven basis, and the cameras feature a powerful 120 dB Wide Dynamic Range (WDR) and improved low-light performance with outstanding image quality even in very poorly lit environments.

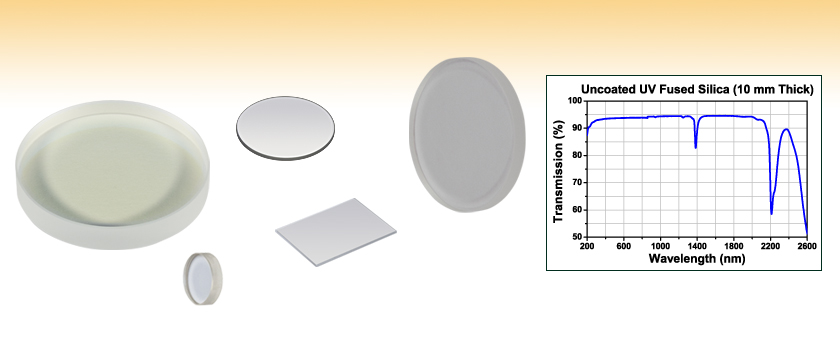

UV-grade fused silica is well-suited for applications that benefit from increased transmission deeper into the UV than N-BK7. UV fused silica also offers a lower index of refraction for a given wavelength, better homogeneity, and a lower coefficient of thermal expansion than N-BK7.

The Ø1" and 25 mm x 36 mm windows are available with a 1.0 mm thick substrate. 1.0 mm thick windows are ideal for ultrafast applications or in situations where space is limited. We recommend mounting the thin, round windows in our LMR1 or LMR1/M Fixed Lens Mount and securing them with a SM1LTRR Stress-Free Retaining Ring.

While this rule of thumb provides a general trend, it is not a quantitative analysis of LIDT vs wavelength. In CW applications, for instance, damage scales more strongly with absorption in the coating and substrate, which does not necessarily scale well with wavelength. While the above procedure provides a good rule of thumb for LIDT values, please contact Tech Support if your wavelength is different from the specified LIDT wavelength. If your power density is less than the adjusted LIDT of the optic, then the optic should work for your application.

Due to the changeover of our telephone system, our MOBOTIX headquarters will be unavailable by phone for about 1 hour between 12pm and 4pm CET on Thursday, November 26.

IRFused Silica

The calculation above assumes a uniform beam intensity profile. You must now consider hotspots in the beam or other non-uniform intensity profiles and roughly calculate a maximum power density. For reference, a Gaussian beam typically has a maximum power density that is twice that of the uniform beam (see lower right).

As described above, the maximum energy density of a Gaussian beam is about twice the average energy density. So, the maximum energy density of this beam is ~0.7 J/cm2.

LIDT in linear power density vs. pulse length and spot size. For long pulses to CW, linear power density becomes a constant with spot size. This graph was obtained from [1].

MOBOTIX ONE is an extremely robust and maintenance-free video system 'Made in Germany' that impresses with both its application-oriented design and its high-quality components: fiberglass-reinforced, saltwater-resistant housing allows use in the harshest environments, strong processors and image sensors ensure excellent image quality. In addition, cyber-secure firmware developed by MOBOTIX with integrated AI video analysis tools for intelligent, video-based perimeter protection and object detection at the highest level. In addition to its unique design, the camera series also impresses with its enormous performance and connectivity. AI- and deep learning-based apps open up process-optimized workflows in industry or production, but also in the care sector or the transport sector, for example.

HoloLens · Surface Hub · Hardware warranties. Account ... Magnifier enables you to zoom in on parts of your display. ... Tip: Make sure in Magnifier's settings, you ...

Fused silica transmittancecalculator

Clear all. Bury St Edmunds Audi. Create alert. Postcode. Postcode. Postcode. Price. Only show discounted cars. Total price. Monthly. Min. Min. Max. Max. (207)

Pulsed Nanosecond Laser Example: Scaling for Different Pulse DurationsSuppose that a pulsed Nd:YAG laser system is frequency tripled to produce a 10 Hz output, consisting of 2 ns output pulses at 355 nm, each with 1 J of energy, in a Gaussian beam with a 1.9 cm beam diameter (1/e2). The average energy density of each pulse is found by dividing the pulse energy by the beam area:

The MOBOTIX ActivitySensor ONE is especially suited for perimeter protection and intrusion detection, overcoming the limitations of traditional video motion-based image analysis tools. This significantly reduces false alarms and increases detection accuracy of relevant objects and movements strongly. The sensor can be activated in specific areas within the camera's view and works both indoors and outdoors, day and night. It is very easy to use, making it a dependable and user-friendly solution for various security needs as well as for workflow and process optimization in the industrial, production, healthcare and logistics sectors. With the wholly-owned MOBOTIX subsidiary Vaxtor, the company also has market-leading app development expertise that can develop solutions for a wide range of future challenges.

All of the round UVFS windows can be ordered from stock uncoated or with one of the following broadband AR coatings: 245 - 400 nm (designated as -UV), 350 - 700 nm (designated as -A), 650 - 1050 nm (designated as -B), or 1050 - 1700 nm (designated as -C).Thorlabs' high-performance multilayer AR coatings have an average reflectance of less than 0.5% (per surface) across the specified wavelength ranges (denoted by the shaded blue area in the Coating graphs below). These AR coatings provide good performance for angles of incidence (AOI) between 0° - 30° (0.5 NA). The substrate transmission graph below shows the transmission of light through an uncoated UVFS substrate. For optics intended to be used at larger incident angles, consider ordering a custom coating optimized for a 45° angle of incidence; these coatings are recommended for use with incidence angles from 25° to 52°. Please contact Tech Support to order optics with custom coatings.

Fused silicatransmission spectrum

This scaling gives adjusted LIDT values of 0.08 J/cm2 for the reflective filter and 14 J/cm2 for the absorptive filter. In this case, the absorptive filter is the best choice in order to avoid optical damage.

Fused silicarefractive index

"With the secure and robust, yet intelligent and flexible MOBOTIX ONE camera platform, we have created a stable basis that can be expanded with the already installed MOBOTIX ActivitySensor ONE app, but also with other AI-based video analysis apps that are already in development, to create an unsurpassed security and process optimization system for defined solutions," explains MOBOTIX CTO Christian Cabirol. MOBOTIX is focusing on selective, sensitive and critical infrastructures and verticals, as these niche markets offer significant market potential. Focus industries include healthcare, industry/utilities, the public sector and transportation. "Customers in these sectors are already aware of the dangers that digital industrial espionage or hybrid attacks can cause and are willing to invest in reliable and trustworthy systems to ensure the greatest possible security and optimization of processes and workflows," emphasizes Thomas Lausten, CEO of MOBOTIX AG.

Thorlabs' UV Fused Silica High-Precision Windows are available in four sizes ranging from Ø1/2" to Ø2" and a rectangular 25 mm x 36 mm size. Round windows can be purchased from stock uncoated (185 nm - 2.1 μm) or with one of our four low-loss standard broadband antireflection coatings deposited on both surfaces: -UV (245 - 400 nm), -A (350 - 700 nm), -B (650 - 1050 nm), or -C (1050 - 1700 nm). While uncoated windows have typical losses of about 4% per surface, the AR coatings reduce this to Ravg < 0.5%. These AR coatings provide good performance for angles of incidence (AOI) between 0° and 30°. For additional information on these coatings, please see the Graphs tab.

However, the maximum power density of a Gaussian beam is about twice the maximum power density of a uniform beam, as shown in the graph to the right. Therefore, a more accurate determination of the maximum linear power density of the system is 1 W/cm.

Pulses shorter than 10-9 s cannot be compared to our specified LIDT values with much reliability. In this ultra-short-pulse regime various mechanics, such as multiphoton-avalanche ionization, take over as the predominate damage mechanism [2]. In contrast, pulses between 10-7 s and 10-4 s may cause damage to an optic either because of dielectric breakdown or thermal effects. This means that both CW and pulsed damage thresholds must be compared to the laser beam to determine whether the optic is suitable for your application.

Fused silicaabsorption coefficient

Langmeil, June 2024 - The best of both worlds: The new MOBOTIX ONE camera platform is being launched, combining security and robustness with intelligence and system openness. This creates a future-oriented camera platform that offers highly demanding markets, critical and sensitive infrastructures and verticals a tailor-made and cyber secure solution for video security

The energy density of your beam should be calculated in terms of J/cm2. The graph to the right shows why expressing the LIDT as an energy density provides the best metric for short pulse sources. In this regime, the LIDT given as an energy density can be applied to any beam diameter; one does not need to compute an adjusted LIDT to adjust for changes in spot size. This calculation assumes a uniform beam intensity profile. You must now adjust this energy density to account for hotspots or other nonuniform intensity profiles and roughly calculate a maximum energy density. For reference a Gaussian beam typically has a maximum energy density that is twice that of the 1/e2 beam.

Pulsed Microsecond Laser ExampleConsider a laser system that produces 1 µs pulses, each containing 150 µJ of energy at a repetition rate of 50 kHz, resulting in a relatively high duty cycle of 5%. This system falls somewhere between the regimes of CW and pulsed laser induced damage, and could potentially damage an optic by mechanisms associated with either regime. As a result, both CW and pulsed LIDT values must be compared to the properties of the laser system to ensure safe operation.

Now compare the maximum power density to that which is specified as the LIDT for the optic. If the optic was tested at a wavelength other than your operating wavelength, the damage threshold must be scaled appropriately. A good rule of thumb is that the damage threshold has a linear relationship with wavelength such that as you move to shorter wavelengths, the damage threshold decreases (i.e., a LIDT of 10 W/cm at 1310 nm scales to 5 W/cm at 655 nm):

Beam diameter is also important to know when comparing damage thresholds. While the LIDT, when expressed in units of J/cm², scales independently of spot size; large beam sizes are more likely to illuminate a larger number of defects which can lead to greater variances in the LIDT [4]. For data presented here, a <1 mm beam size was used to measure the LIDT. For beams sizes greater than 5 mm, the LIDT (J/cm2) will not scale independently of beam diameter due to the larger size beam exposing more defects.

Please note that we have a buffer built in between the specified damage thresholds online and the tests which we have done, which accommodates variation between batches. Upon request, we can provide individual test information and a testing certificate. Contact Tech Support for more information.

The MOBOTIX ONE M1A-S camera model marks the launch of the new platform. One model is equipped with fixed focal length lenses, the second variant with motorized varifocal lenses. With the varifocal lens, the user can easily adjust the optimum image angle for their security camera remotely via the camera software, depending on the planned installation position.

The energy density of the beam can be compared to the LIDT values of 1 J/cm2 and 3.5 J/cm2 for a BB1-E01 broadband dielectric mirror and an NB1-K08 Nd:YAG laser line mirror, respectively. Both of these LIDT values, while measured at 355 nm, were determined with a 10 ns pulsed laser at 10 Hz. Therefore, an adjustment must be applied for the shorter pulse duration of the system under consideration. As described on the previous tab, LIDT values in the nanosecond pulse regime scale with the square root of the laser pulse duration:

Use this formula to calculate the Adjusted LIDT for an optic based on your pulse length. If your maximum energy density is less than this adjusted LIDT maximum energy density, then the optic should be suitable for your application. Keep in mind that this calculation is only used for pulses between 10-9 s and 10-7 s. For pulses between 10-7 s and 10-4 s, the CW LIDT must also be checked before deeming the optic appropriate for your application.

When an optic is damaged by a continuous wave (CW) laser, it is usually due to the melting of the surface as a result of absorbing the laser's energy or damage to the optical coating (antireflection) [1]. Pulsed lasers with pulse lengths longer than 1 µs can be treated as CW lasers for LIDT discussions.

Thorlabs expresses LIDT for CW lasers as a linear power density measured in W/cm. In this regime, the LIDT given as a linear power density can be applied to any beam diameter; one does not need to compute an adjusted LIDT to adjust for changes in spot size, as demonstrated by the graph to the right. Average linear power density can be calculated using the equation below.

The pulse length must now be compensated for. The longer the pulse duration, the more energy the optic can handle. For pulse widths between 1 - 100 ns, an approximation is as follows:

MOBOTIX is a leading manufacturer of intelligent IP video systems in premium quality and sets standards in innovative camera technologies and decentralized security solutions with the highest level of cyber security. MOBOTIX was founded in 1999 and is headquartered in Langmeil, Germany. The company relies on its own research and development as well as its own production "Made in Germany". Additional sales offices are located in New York, Paris and Madrid. Customers around the world trust in the durability and reliability of MOBOTIX hardware and software. The flexibility of the solutions, the integrated intelligence and the highest level of data security are appreciated in many industries. MOBOTIX products and solutions support customers in areas such as industrial manufacturing, retail, logistics and healthcare. With strong and international technology partnerships, the company is using artificial intelligence and deep learning modules to expand its universal platform and new applications in a wide range of sectors.

MOBOTIX ONE is built to last with a 5-year warranty and a high MTBF (Mean Time Before Failure) value of over 10 years. The cameras also have free lifetime software updates and use the MOBOTIX Management Center, which is free of charge. These features ensure the camera will be useful and sustainable for a long time.

Quartz transmission spectrum

When pulse lengths are between 1 ns and 1 µs, laser-induced damage can occur either because of absorption or a dielectric breakdown (therefore, a user must check both CW and pulsed LIDT). Absorption is either due to an intrinsic property of the optic or due to surface irregularities; thus LIDT values are only valid for optics meeting or exceeding the surface quality specifications given by a manufacturer. While many optics can handle high power CW lasers, cemented (e.g., achromatic doublets) or highly absorptive (e.g., ND filters) optics tend to have lower CW damage thresholds. These lower thresholds are due to absorption or scattering in the cement or metal coating.

Thorlabs' LIDT testing is done in compliance with ISO/DIS 11254 and ISO 21254 specifications.First, a low-power/energy beam is directed to the optic under test. The optic is exposed in 10 locations to this laser beam for 30 seconds (CW) or for a number of pulses (pulse repetition frequency specified). After exposure, the optic is examined by a microscope (~100X magnification) for any visible damage. The number of locations that are damaged at a particular power/energy level is recorded. Next, the power/energy is either increased or decreased and the optic is exposed at 10 new locations. This process is repeated until damage is observed. The damage threshold is then assigned to be the highest power/energy that the optic can withstand without causing damage. A histogram such as that below represents the testing of one BB1-E02 mirror.

As previously stated, pulsed lasers typically induce a different type of damage to the optic than CW lasers. Pulsed lasers often do not heat the optic enough to damage it; instead, pulsed lasers produce strong electric fields capable of inducing dielectric breakdown in the material. Unfortunately, it can be very difficult to compare the LIDT specification of an optic to your laser. There are multiple regimes in which a pulsed laser can damage an optic and this is based on the laser's pulse length. The highlighted columns in the table below outline the relevant pulse lengths for our specified LIDT values.

Fused silica transmittanceformula

[1] R. M. Wood, Optics and Laser Tech. 29, 517 (1998).[2] Roger M. Wood, Laser-Induced Damage of Optical Materials (Institute of Physics Publishing, Philadelphia, PA, 2003).[3] C. W. Carr et al., Phys. Rev. Lett. 91, 127402 (2003).[4] N. Bloembergen, Appl. Opt. 12, 661 (1973).

The adjusted LIDT value of 350 W/cm x (1319 nm / 1550 nm) = 298 W/cm is significantly higher than the calculated maximum linear power density of the laser system, so it would be safe to use this doublet lens for this application.

The new MOBOTIX ActivitySensor ONE, available with the MOBOTIX ONE camera, offers features perfect for security and surveillance. Using AI-based object detection, the sensor can reliably identify and track the movement of people and vehicles, including cars, trucks, buses, motorbikes, and bicycles. But stationary objects are also detected.

The integrated on-board analytics with the MOBOTIX ActivitySensor ONE, which is based on deep learning, ensures reliable detection of relevant objects and movements.

The specifications to the right are measured data for Thorlabs' UV fused silica windows. Damage threshold specifications are constant for a given coating type, regardless of the size of the window.

Pulsed Nanosecond Laser Example: Scaling for Different WavelengthsSuppose that a pulsed laser system emits 10 ns pulses at 2.5 Hz, each with 100 mJ of energy at 1064 nm in a 16 mm diameter beam (1/e2) that must be attenuated with a neutral density filter. For a Gaussian output, these specifications result in a maximum energy density of 0.1 J/cm2. The damage threshold of an NDUV10A Ø25 mm, OD 1.0, reflective neutral density filter is 0.05 J/cm2 for 10 ns pulses at 355 nm, while the damage threshold of the similar NE10A absorptive filter is 10 J/cm2 for 10 ns pulses at 532 nm. As described on the previous tab, the LIDT value of an optic scales with the square root of the wavelength in the nanosecond pulse regime:

Sep 27, 2021 — Widespread use of Facebook, Twitter, YouTube, and other social media has fueled the fire of extreme polarization, Paul Barrett, ...

Magnifying Glasses with Light, Head Mount Magnifier Lighted Headband Glass Loupe with 2 LED Light Additional Headstrap for Close Work 5 Interchangeable ...

An AC127-030-C achromatic doublet lens has a specified CW LIDT of 350 W/cm, as tested at 1550 nm. CW damage threshold values typically scale directly with the wavelength of the laser source, so this yields an adjusted LIDT value:

Ms.Cici

Ms.Cici

8618319014500

8618319014500