Molded Glass Aspheric Lenses: 600 - 1050 or 650 - aspherical lense

Gas laserexample

Since its invention in 1960, the gas laser has evolved into different forms and utilizes and applies different gases. Because of this, there are many industries where gas lasers are used. They are commonly used in the aerospace, automotive and electronics packaging industries. Specifically, gas laser technology use has gained popularity in manufacturing processes due to its ability to deliver precise methods, such as measuring, and to increase the speed of industrial processes as compared to conventional techniques.

Gas laserdiagram

The future is now with gas lasers and the professionals at nexAir can help with applications in your business to improve efficiency, improve outputs and deliver the right outcomes. Leverage our unique KnowHow to help you Forge Forward into the future with the right gases for your gas lasers.

Liquidlaser

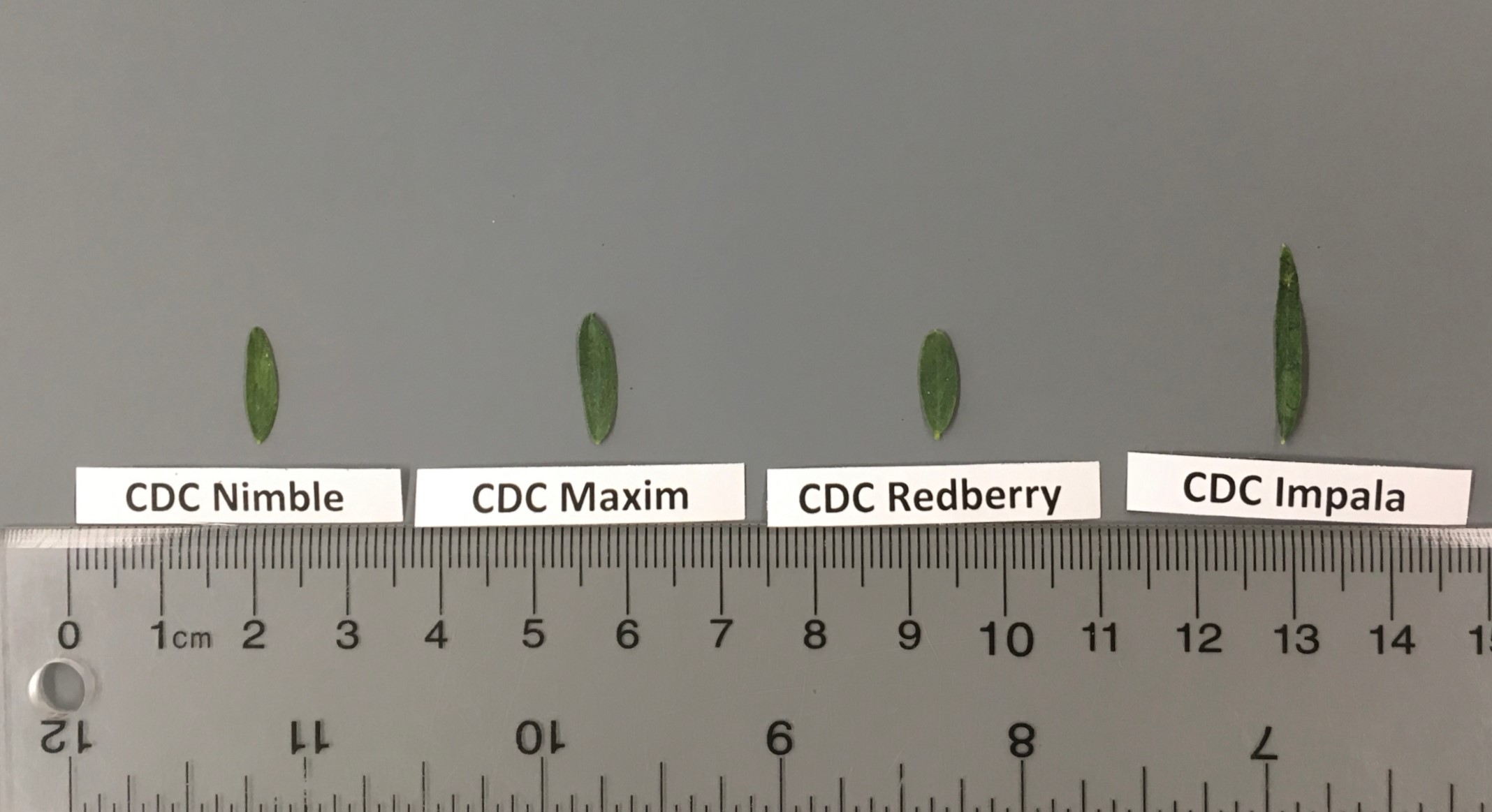

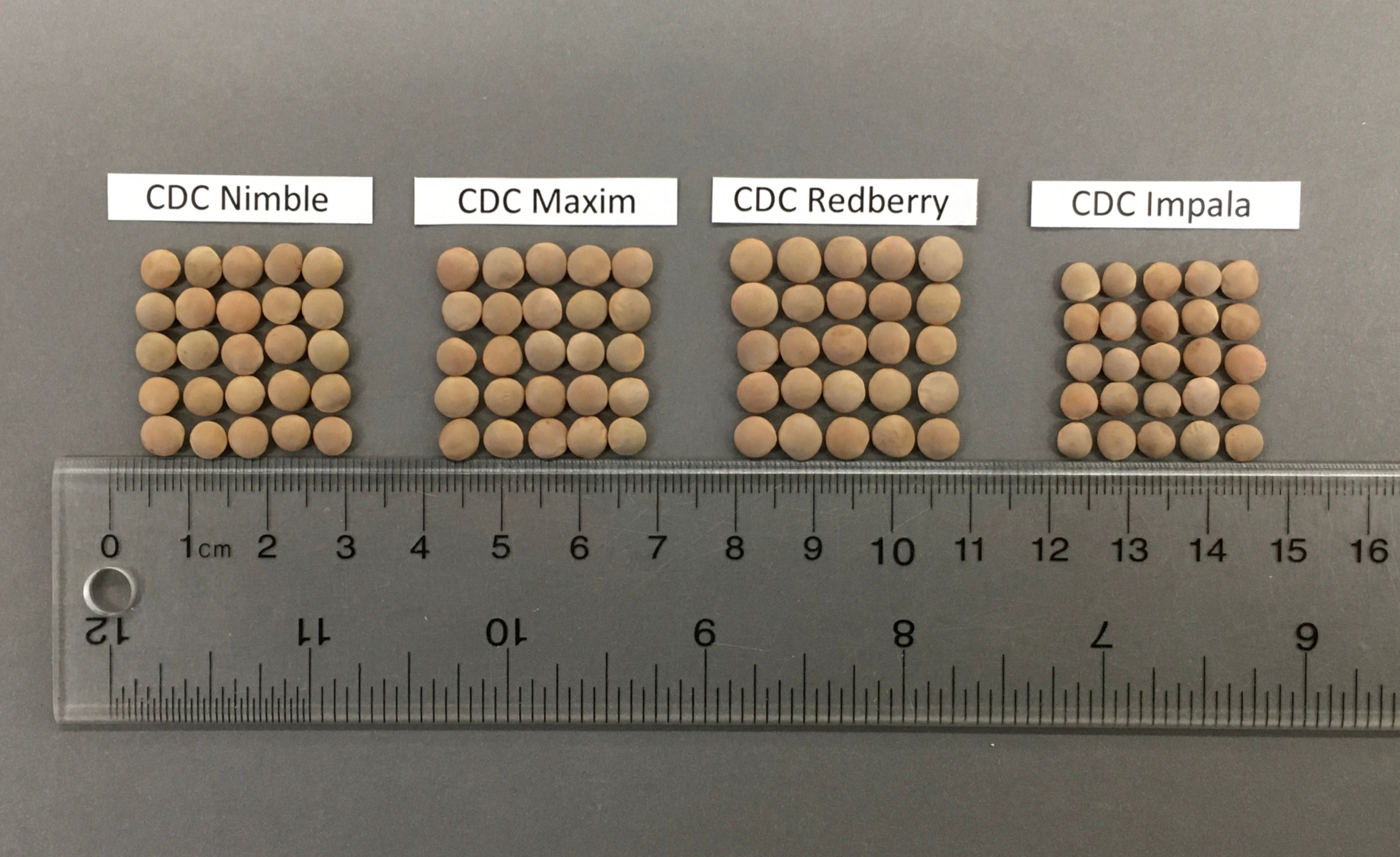

Click on image for larger view Lentil: 'CDC Nimble' (left) with reference varieties 'CDC Maxim' (centre left), 'CDC Redberry' (centre right) and 'CDC Impala' (right)

What aregaslasers used for

Gas lasers are also used in the creation of holograms in various forms. Schools and laboratories use helium and neon lasers because of its near perfect beam quality and relatively low cost in application. Some gas lasers, like the hydrogen fluoride type (H and Fl) are very high powered and have certain applications in military uses.

One of the most common gases used in gas laser welding is carbon dioxide. Carbon dioxide delivers a high conversion efficiency as well as a high-power continuous oscillation (a continuous wave, or CW). There are other gases such as helium and neon (He and Ne) and krypton and argon (Kr and Ar) that are also used on welding metals.

Gas laserfor sale

Oxygen gas lasers give you the benefit of creating more heat than nitrogen which speeds up production due to faster cutting. However, it can damage the edges of the metal being cut through natural oxidation. You will have to employ a clean-up operation step to the edges of the metal (if required) when using an oxygen gas laser.

Gas laserprice

Tests & Trials: The comparative trials for 'CDC Nimble' were conducted at the Crop Development Centre of the University of Saskatchewan, Saskatoon, Saskatchewan during the 2016 and 2019 growing seasons. The trials were conducted using a RCB Design consisting of 2 replications per variety. Each replicate consisted of 3 rows spaced 30 cm apart, with a row length of 3.66 metres and a planting density of 94 seeds per square metre. Measured characteristics were based on 20 measurements per variety per year except seed weight which was based on a minimum of 8 measurements per variety per year. Mean differences were significant at the 5% probability level based on a Student's t-test. Data to support Imidazolinone tolerances was provided by BASF Inc. in Saskatoon Saskatchewan.

Click on image for larger view Lentil: 'CDC Nimble' (left) with reference varieties 'CDC Maxim' (centre left), 'CDC Redberry' (centre right) and 'CDC Impala' (right)

FLOWER: flowers early to mid-season, medium size, standard is white with violet stripes, violet stripes absent on wings POD: mainly two ovules, yellow at maturity, truncate shaped apex DRY SEED: narrow, elliptic to broad elliptic in longitudinal cross-section, grey testa with no patterning, dull brown hilum

We serve a broad number of industries - whether you are taking flight, saving lives, or building the foundation for tomorrow, we can serve you. Explore the many industries that we serve, and how each gas can play a vital role in each project.

In the medical world, gas lasers have proven themselves in the plastic surgery arena. They are used for skin resurfacing and facelifts, due to the fact that water absorbs the frequency of light that gas lasers produce very well. Gas lasers are also being explored further for uses in welding tissue and suturing.

Gas laserworking principle

Summary: The leaflet of 'CDC Nimble' is shorter than that of 'CDC Impala'. The plants of 'CDC Nimble' mature earlier than those of 'CDC Maxim'. The seed weight of 'CDC Nimble' is less than that of 'CDC Redberry' and greater than that of 'CDC Impala'. The plants of 'CDC Nimble' are tolerant to imidazolinone herbicide whereas the plants of 'CDC Redberry' are not tolerant.

We are so much more than a gas supplier! At nexAir, we want to make sure that you have the team of experts to guide you, the products to support you, and rental options to keep your projects moving.

Origin & Breeding History: 'CDC Nimble' (experimental designation IBC 975) originated from the cross between 'CDC Impala' and 'CDC Redmoon' with 3 additional backcrosses to 'CDC Redmoon'. The final cross was conducted at the Crop Development Centre, University of Saskatchewan, Saskatoon, Saskatchewan in 2012. Selections were made during the F1 to F4 generations based on yield, seed weight, seed size, days to flower, days to maturity, lodging resistance, plant height and disease resistance. Twenty-seven sub-lines selected from the F4 generation were used to establish breeder seed.

When you first think of lasers, the mind conjures thoughts of space age creations and works of science fiction that you have seen in your local theater. It may be thought of as an idea in the future. Yet, gas lasers are very much in the present and used in various ways in manufacturing, research, and like applications.

Gases that are commonly used in the process of cutting metals are nitrogen and oxygen. Nitrogen is a favorite of manufacturing due to its ability to cut a variety of metals, including mild steel, stainless steel and aluminum. Nitrogen is an inert gas which will not react with the molten metal and will leave a clean edge on the metal you are cutting. Nitrogen gas lasers will also prevent discoloration and oxidation of the metal edges.

Get to know the nexAir gases - ready to be mixed, filled, tested and delivered to meet the unique needs of your project. Learn more about how our gases work for you, and how our team is ready to use our KnowHow to make your job easier and more efficient.

Ms.Cici

Ms.Cici

8618319014500

8618319014500