MODULATOR Definition & Meaning - modulateur def

Photon polarization

It is an angle of incidence. It is the most important parameter of a microscope. NA measures its ability to gather light. It’s an important factor to determine resolution, depth of focus, and the brightness of images. Objectives with a larger NA gather a wider range of light, resulting in brighter, higher resolution images.

NA is also important to observe very fine structures or detect dim signals during fluorescence observation. When determining which microscope objective will resolve the smallest feature in your specimen, think about the NA. As you weigh your options, keep in mind that numerical aperture typically ranges between 0.10 to 1.25.

The resolution of the microscope objective determines the smallest distance between two objects that can be observed. It is directly proportional to the illumination wavelength of light and inversely proportional to the NA.

Note that they can work only in a limited wavelength range, since the interference effects in the multilayer coating are of course wavelength-dependent. However, operation in a range of few hundred nanometers is possible.

Note: the article keyword search field and some other of the site's functionality would require Javascript, which however is turned off in your browser.

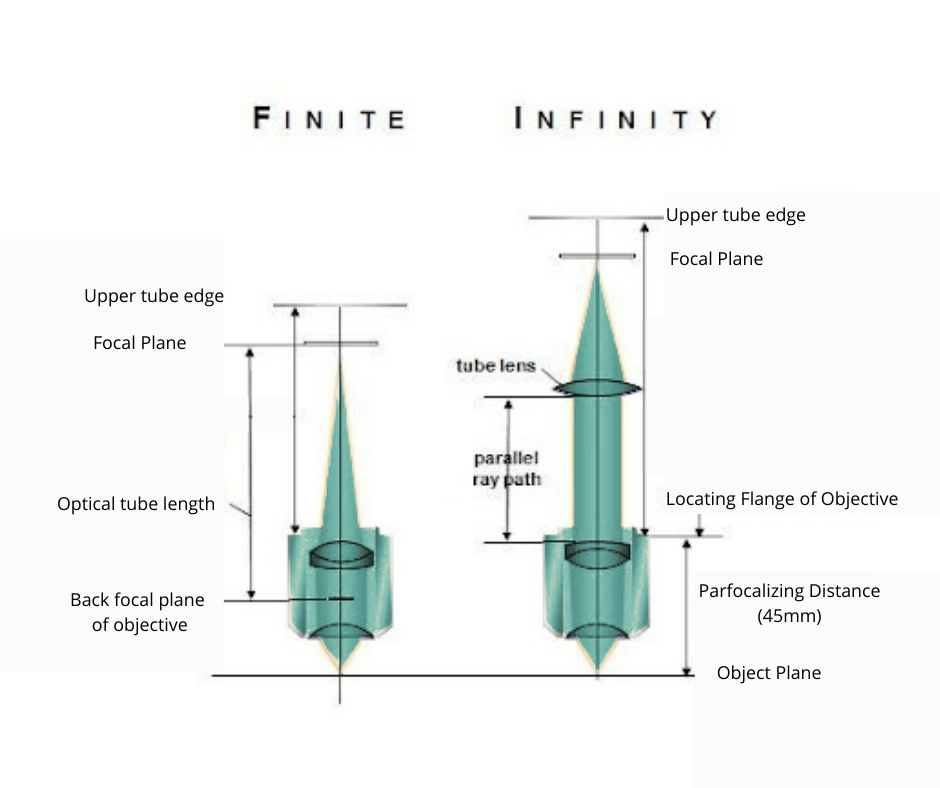

In a finite conjugate design, the objective focuses light from the object into the focal plane of the eyepiece. An infinite corrected objective collects light from the object and forms a parallel beam that passes through a tube lens. The advantage of this design is that additional optical elements, such as polarizers, filters, and wave-plates, can be placed in between the tube lens and the objective without interfering with the focusing of the beam. The infinite conjugate design is often used in fluorescence microscopes, which rely on filters.

Polarization

Using our advertising package, you can display your logo, further below your product description, and these will been seen by many photonics professionals.

Birefringence

As with all of our custom laser optics and polarizers, PPD's IBS coated polarizing beam splitters exhibit low absorption, high extinction (Tp/Ts) and high damage thresholds, making them ideal for use with high energy Nd:YAG and fibers lasers as well as other high-power pulsed and CW laser systems throughout the visible and near-infrared.

Note: this box searches only for keywords in the titles of articles, and for acronyms. For full-text searches on the whole website, use our search page.

For other directions of linear polarization with an angle <$\theta$> against the “passing” direction, the transmissivity exhibits a <$\cos^2 \theta$> dependence. That can be understood by considering that linear polarization state as a linear superposition of the “passing” and the “blocked” state.

Most types for crystal polarizers like Glan-Taylor, Rochon, crystal wedge etc. covering the spectral range from 170 nm to 6 µm are available from stock. Thin-film polarizers used at Brewster or 45° angle of incidence feature high damage threshold and can be used for demanding applications. ALPHALAS also offers customer-specific polarizers.

The almost complete transmission and reflection provided by our dichroic polarizers means that very little stray light gets through the imaging system. This results in high contrast image and a very good signal to noise ratio, as compared to other polarizers.

polarizer中文

There are reflective polarizing films, which largely transmit light with a certain linear polarization direction while reflecting (not absorbing) most of the light. Such films are widely used for liquid crystal displays, which need polarized illumination. While at least half of the generated light would normally be lost at the entrance polarizer, that part can at least be partly “recycled” if it is reflected towards the light source and thereby at least partly converted into the right polarization direction.

OPTOMAN will provide an optimal solution in terms of extinction ratio (10'000:1 is possible), angle of incidence (various choices depending on application), and damage threshold ( > 49.4 J/cm2 @ 1064 nm, 10 ns, 100 Hz can be achieved in some configurations). Broadband configurations for femtosecond applications are also feasible.

Optical correction such as achromatic, apochromatic, plan and semi-plan are often denoted on the objective in order to show the design of the objective. Plan and semi-plan objectives correct for field curvature. Field curvature often results in blurred images on the periphery and correction for this helps produce good quality images. Whereas plan objectives correct better, allowing for better display (over 80 per cent) of field flat, semi-plain objectives produce about 65 per cent.

The reason for the use of many different designs of birefringent polarizer designs is that different applications can have quite different requirements on the polarizers, and no design can meet all requirements.

Attach each objective to each lens mount hole of the revolving nosepiece, starting from the lowest magnification objective and increasing the magnification in the clockwise direction seen from the bottom. By attaching objectives in this way, the objectives can be switched in ascending order of magnification

Is the distance from the objective’s front lens to the closest surface of the coverslip when the specimen is in focus? WD is inversely proportional to the NA, which means that higher NA objectives typically have low working distances.

Absorptive filters can handle only quite limited optical powers (have a low optical damage threshold) because the absorbed power is converted to heat, and the sheet can easily be damaged by overheating it. In the case of simple polymer sheet polarizers, an optical intensity of only 1 W/cm2 may already be critical.

They can exhibit both a wide field of view and a high extinction ratio. The wide field of view is important for photons generated by parametric fluorescence, a common method used in quantum optics experiments.

For low-power applications, Polaroid filters (polarizing sheets, sheet polarizers) are often used. These are also called dichroic. They consist of a special doped plastic sheet (a polymer materials), which has been stretched in one direction, such that the polymer chains are more or less aligned along one axis. Light a polarization direction along the chains is strongly absorbed, whereas the absorption is weak for light with a polarization direction perpendicular to these. The polymer sheet is usually mounted in some solid holder, which may have marks indicating the direction of polarization for maximum transmission.

Half wave plate

At Knight Optical, we stock a vast range of polarisers suitable for a variety of applications, including linear and circular sheet polarisers, achromatic waveplates, zero and low order quartz retarders, and calomel infrared polarisers. We also offer custom polarisation optics including crystal polarisers, as well as Lyot depolarisers.

Shalom EO offers a full portfolio of polarizers and waveplates: Glan Laser polarizers or prisms, Glan Taylor polarizers or prisms, Glan Thompson polarizers or prisms, Wollaston polarizers, Rochon polarizers, high power laser line PBS, polarizing cube beamsplitters, non-polarizing beamsplitter cubes, polarizing plane rotators and achromatic depolarizers are also provided.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

There are polarizing cube beam splitters where the dielectric coating is applied to one 45° prism and another 45° prism is cemented to the coating, such that overall one obtains a cube.

P-polarized light

Denoted by a number (such as 0.17mm) the cover slip thickness is labeled on the objective to note the type of cover slip that should be used. A cover slip changes the way light is refracted from the specimen. Therefore, it is important to ensure that the right cover slip is used in order to produce a good quality image. Zero(0) denotes no coverslip to use. Dash(-) denotes use of coverslip or no cover slip, it does not matter.

A polarizer is a kind of optical filter where the light transmission depends strongly on the polarization state. Normally, light with linear polarization in a certain direction is passed, and light polarized in an orthogonal direction is either absorbed or sent to a different direction.

OPTOMAN offers thin film polarizers, that are the optimal choice for polarizing high energy laser light. Thin Film Polarizers accomplish this task with a high efficiency level due to negligible absorption within the coating, transmittance (Tp) higher than 99%, and reflectance (Rs) as high as 99.99%.

A more modern type of absorptive polarizer is based on silver or copper nanoparticles embedded in a thin glass plate. These glass polarizers are much more expensive and not available in very large sizes, but offer a substantial better performance in terms of polarization extinction ratio. Laminated versions are mechanically more robust and cause lower wavefront distortions.

LASEROPTIK offers various types of polarizers, including thin-film (TFP) devices, cube polarizers (CP) and broadband polarizers (BBPOL). We can work in different wavelength ranges from the mid-IR (2.1 μm) to the UV (157 nm).

Dayoptics has newly developed thin film polarizers with 45° incidence. We can assure high transmission >95% and high reflection >99%.

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Dichroism

There are many different types of objectives available for microscopes, but without a basic understanding of how they work, it can be difficult to know which ones are best suited to the specific needs you have. That's why this article takes you through the basics points to keep in mind ,so that you'll have a better idea of what type is right for your needs.

Artifex Engineering offers a wide range of polarizers including crystal polarizers (Glan-Taylor, Glan-Thompson, …), dielectric polarizers, dichroic polymer polarizer sheets and wire grid polarizers. In addition, we offer polarization rotators and depolarizers. As with all our products, we offer customization for our polarizers. Visit our product page for more detailed information for each polarizer. We look forward to your inquiry.

Shalom EO offers optical prisms of multiple types which are ideal for applications of ray deviation and adjusting orientation of an image, including: right angle prisms, corner cube retroreflectors, wedge prisms, Brewster angle prisms and equilateral prisms, in addition to penta prisms, Dove prisms and roof prisms and Porro prisms. A large list of materials can be used: BK7, N-BK7, UV-grade fused silica, N-SF11, CaF2, Ge, ZnSe.

EKSMA Optics offers a complete range of polarization optics: thin-film polarizers, Brewster windows, cube polarizing beamsplitters, Glan laser polarizing prisms, Rochon and Wollaston prisms.

In practice, polarizers are not ideal. In particular, they do not provide perfect extinction. (See below for a definition of the extinction ratio.) Also, real polarizers absorb or reflect some part of the optical power, and the absorbed part may lead to thermal effects such as beam distortions. Even at low power levels, some degree of wavefront distortions occurs. The performance depends very much on the used type of polarizer (see below).

Much higher optical powers can be handled by polarizers where light with the “rejected” polarization state is not absorbed but only sent to some other direction. (If it needs to absorbed later on, a beam dump can stand much higher powers than an optical element.) The most common type of polarizing beam splitters exploit birefringence of a transparent crystalline material such as quartz (SiO2), calcite (CaCO3), yttrium vanadate (YVO4), beta barium borate (BBO) or magnesium fluoride (MgF2). Often, two pieces of such material with different orientations of the optical axis are cemented together (or joined with a small air space). The device is often mounted in a polymer housing, which may also contain a beam dump for light with the rejected polarization direction.

An advantage of thin-film polarizers is that they can be made with rather large dimensions, which is more difficult with crystalline (birefringent) polarizers.

Thorlabspolarizer

On the objective, this is usually denoted by an X next to a numeric value (100X, 10X etc). On the other hand, objectives will also have a colored band around the circumference of the objective that indicates the magnification of the objective. For instance, a yellow band around the objectives (lower part of the objective) indicates that it is a 10x objective.

For non-cubic polarizers, used birefringent crystal materials include alpha-BBO, YVO4, quartz and MgF2. Modules including custom shapes and rectangular or round mount options are available. Please visit our website for more information.

Selection of a polarizer for an application can be a relatively complex task, as many different aspects have to be taken into account. The different requirements for different applications are also the reason why so many polarizer designs are in use.

Anti-reflection(AR) coating options are single layer MgF2 coating, broadband AR coating and laser line wavelength V-type coating. Reflective aluminium coating is also provided.

At Shanghai Optics we produce some of the highest quality dichroic polarizers. Our dichroic plate beamsplitters are manufactured with a special design and proprietary manufacturing approach, allowing us to attain steep edges and flat, high reflection and transmission bands.

Perkins Precision Developments (PPD) manufactures Brewster’s angle polarizers as well as 45 degree plate polarizers for high performance with easy alignment. Because we utilize Ion Beam Sputtering (IBS) coating technology, our dielectric thin film plate polarizers are environmentally stable, thus there is no spectral shift caused by either time, moisture or temperature. The predictability and repeatability of IBS thin film coatings allow us to guarantee high transmission at a specific angle of incidence, eliminating the need to angle tune the optical component in order to achieve optimal performance.

Note that a high performance of a polarizer is more difficult to achieve in extreme wavelength regions, in particular in the ultraviolet spectral region.

The objective depth of field is the axial range, which enables you to focus an objective without any considerable change in image sharpness. This value varies radically from low to high numerical aperture objectives; it usually decreases as the numerical aperture increases.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

There are different kinds of thin-film polarizers. Thin-film plate polarizers (Figure 3) consist of a dielectric coating on some glass substrate. (Note that the substrate does not need to be birefringent.) For non-normal incidence (in a certain range of incidence angles), the reflectivity of the coating can be strongly polarization-dependent. It is possible to have the “rejected” beam at a deflection angle of 90°, which is often convenient. However, many thin-film plate polarizers are operated at Brewster's angle, so that no anti-reflection coating is required on one side.

Each objective and eyepiece has a specific purpose or function. Objective lenses magnify the image that enters the objective and bring it to a sharp, clear focus. Eyepieces take the light that has been focused by the objective lenses and magnify it further so that you can see it. The magnification power is measured by objective magnification multiplied by eyepiece magnification.

Most polarizers act based on linear polarizations. However, one can also construct devices passing light with a certain circular polarization, usually using one or more quarter waveplates or possibly Faraday rotators in conjunction with a linear polarizer.

Similar sheets are used for polarizing glasses (also called polarized glasses). In the case of sunglasses, only vertically polarized light is transmitted. This reduces glare from water surfaces, for example, as horizontally polarized light experiences stronger reflection at such surfaces. In the case of polarizing glasses for 3D viewing, one eye gets the vertical polarization and the other eye the horizontal one. In this way, a 3D display can transmit separate images for the eyes.

The higher the NA, the smaller the distance between two objects. As we mentioned previously, choosing the right NA for your application is crucial in determining the resolution of your microscope system.

Note that a polarizer can not convert any polarization of input light into the wanted polarization; this is physically not possible. It can only remove light with the unwanted polarization.

Why are Glan–Thompson polarizers used in preference to Glan–Taylor or Glan–Laser prisms when used as infrared polarization analyzers in correlated photon experiments?

Wire grid polarizers are made by fabricating very narrow (sub-wavelength) metal stripes on a glass substrate (using a lithographic technique) or in a free-standing arrangement (for longer wavelengths). Such devices reflect s-polarized light, while p-polarized light is transmitted. They can be used at very high average power levels.

Avantier produces high-quality dichroic polarizers with steep edges and flat reflection and transmission bands. Our polarizers provide almost complete transmission and reflection, resulting in high contrast images and good signal to noise ratios. They feature a UV grade fused silica, JGS1, or JGS2 substrate, and have a higher damage threshold than plastic polarizers. Our coatings meet MIL-STD-810F and MIL-C-484971 requirements, and we offer various options.

Our dichroic polarizers feature a UV grade fused silica, JGS1, or JGS2 substrate, coated with a hard dielectric coating. These glass polarizers have a much higher damage threshold than their plastic counterparts, and are suitable for precision applications. Our coatings fully meet MIL-STD-810F and MIL-C-484971 requirements, and we have a variety of different options available.

Ms.Cici

Ms.Cici

8618319014500

8618319014500