Modulation Transfer Function | Nikon's MicroscopyU - mtf optics

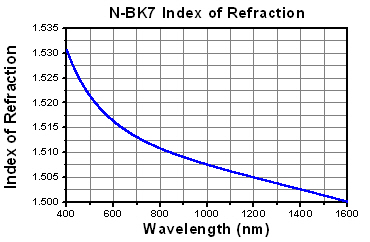

Click on the image to download the raw data. In the thick lens equation, use the index of refraction for N-BK7 at the wavelength of interest to approximate the wavelength-dependent focal length of any of the plano-convex lenses.

Polarization oflightnotes PDF

Our high-performance multilayer AR coatings have an average reflectance of less than 0.5% (per surface) across the specified wavelength ranges and provide good performance for angles of incidence (AOI) between 0° and 30° (0.5 NA). For optics intended to be used at large incident angles, consider using a custom coating optimized at a 45° angle of incidence; this custom coating is effective from 25° to 52°. The plot shown below indicates the performance of the standard coatings in this family as a function of wavelength. Broadband coatings have a typical absorption of 0.25%, which is not shown in the reflectivity plots.

The focal length of a thick spherical lens can be calculated using the thick lens equation below. In this expression, nl is the index of refraction of the lens, R1 and R2 are the radii of curvature for surfaces 1 and 2, respectively, and d is the center thickness of the lens.

Polarized light physicsformula

Learn about the general structure of a eukaryotic gene, the transcription factors, and post-transcriptional regulation....

Polarized light physicsequation

N-BK7 is probably the most common optical glass used for high-quality optical components. It is typically chosen whenever the additional benefits of UV fused silica (i.e., good transmission further into the UV and a lower coefficient of thermal expansion) are not necessary.

What is polarization of waves inPhysics

Definition noun Light in which electromagnetic vibrations oscillate repeatedly in only one direction perpendicular to the direction of propagation. Supplement Light polarization is a property of light waves that depicts the direction of their oscillations. A polarized light vibrates or oscillates in only one direction. This is in contrast to a nonpolarized light that vibrates..Read More

Below is the transmission curve for N-BK7, a RoHS-compliant form of BK7. Total Transmission is shown for a 10 mm thick, uncoated sample and includes surface reflections. Each N-BK7 bi-convex lenses can be ordered uncoated (available below) or with one of the following broadband AR coatings: 350 - 700 nm (designated with -A), 400 - 1100 nm (designated as -AB), 650 - 1050 nm (designated as -B), or 1050 - 1700 nm (designated as -C).

Thorlabs' retaining rings are used to secure unmounted optics within lens tubes or optic mounts. These rings are secured in position using a compatible spanner wrench. For flat or low-curvature optics, standard retaining rings manufactured from anodized aluminum are available from Ø5 mm to Ø4". For high-curvature optics, extra-thick retaining rings are available in Ø1/2", Ø1", and Ø2" sizes.

Polarizedand unpolarizedlight

Plants are responsible for incredible feats of molecular transformation. Plant processes, such as photosynthesis, photop..

Definition noun Light in which electromagnetic vibrations oscillate repeatedly in only one direction perpendicular to the direction of propagation. Supplement Light polarization is a property of light waves that depicts the direction of their oscillations. A polarized light vibrates or oscillates in only one direction. This is in contrast to a nonpolarized light that vibrates in many directions. A polarized light may be plane-polarized, circularly polarized or elliptical-polarized light based on the net direction of the vibrations. Many animals are able to perceive and use certain forms of polarized light. For instance, insects use plane-polarized light for navigational purposes. A naked human eye is not very sensitive to polarized light but with practice, or with the use of a polarizer, humans can then perceive a polarized light such as the Haidinger’s brush phenomenon. Compare: nonpolarized light Related term:

Genes are expressed through the process of protein synthesis. This elaborate tutorial provides an in-depth review of the..

IntroductionThorlabs has a series of quality control procedures in order to ensure our singlets meet our standards and specifications. This starts with in-process inspections of the lens’ imaging capabilities and ends with a final inspection of surface quality and dimensions. Specifications for particular products can be found in their linked documentation by clicking the symbol. This tab will take you through the general process used to check for quality.Singlet Quality PracticesIn-process inspection begins once the singlet has been shaped to specifications. Focal length, surface irregularity, and surface power are checked, following sampling plan Level VI given in MIL-PRF-13830B (see below). These three specifications are imperative for proper imaging. Surface irregularity of parts is kept to below either a quarter wavelength or a half wavelength at 633 nm, depending on the material of the singlet. Below is a graph of over 200 batches of singlets with irregularity data of both their front and back sides.At this point, some uncoated singlets will proceed to final inspection, while others will receive an antireflective (AR) coating. The application of optical coatings has its own in-process inspections. To ensure the AR coating is applied properly, we verify both reflectance and transmission performance by scanning witness pieces using spectrophotometry; the material of these 2 mm thick witness samples matches the other parts in the run. For reflectance verification, we use at least one witness sample for each coating run. Transmitting optics receive two AR coatings, one on each surface, so for the verification of transmission, we use one witness sample that is also coated on both of its sides. Large runs use multiple witness samples to ensure the uniformity across the deposition chamber. By testing coating performance during every run, variance over time is kept low. To see how coatings vary, see the table below.Final inspection of both uncoated and AR-coated singlets includes a batch check of diameter and thickness and a 100% visual check to ensure that the surface quality, chamfer, and clear aperture meet our published specifications. While surface quality is cosmetic to a degree, scratches, digs, and other inclusions in the surface of a part can increase the chances of damage to the singlet when used with high-power sources. These inspections are done in a clean, dark room under lighting that meets the requirements of MIL-PRF-13830B. Inspection under a single light source in a dark room allows for inconsistencies in the glass to be located without being obscured by glare or reflections.MIL-PRF-13830B: Performance Specifications for Optical ComponentsMIL-PRF-13830B is a document created by the U.S. Army Armament Research, Development and Engineering Center's Defense Quality and Standardization Office for the specifications covering how finished optical components should be manufactured, assembled, and inspected. While primarily for use in letting the military dictate how products they use can be incorporated into their equipment, these standards have been adopted by many optics manufacturers. To download a copy of the full document, click here.

Polarized light physicsnotes

Lotic communities have conditions that are rather harsh for typical plants. Thus, the diversity of plant species in loti..

What is plane polarisedlightin Chemistry

Disclaimer: The coated transmission data presented here are of 2 mm thick witness samples of N-BK7 or equivalent glass, and all the data here are typical. Some variations in performance data will occur from lot to lot. Please contact Technical Support with any questions regarding the use or reliability of these data.

The content on this website is for information only. It is not intended to provide medical, legal, or any other professional advice. Any information here should not be considered absolutely correct, complete, and up-to-date. Views expressed here do not necessarily reflect those of Biology Online, its staff, or its partners. Before using our website, please read our Privacy Policy.

For bi-convex lenses, where the front and back radii of curvature are equal in magnitude and opposite in sign, R1 = -R2 = R, we have

Polarized light physicsexamples

The focal length of the lens calculated using the simplified thick lens equation directly above is the distance between the second (back) principle plane (H") and the position at which a collimated beam incident on the curved surface of the bi-convex is focused. The same analysis can be performed using a point source and the first (front) principle plane (H'). The principle plane positions of a thick lens can be calculated with the following equations:

Bryophytes (nonvascular plants) are a plant group characterized by lacking vascular tissues. They include the mosses, th..

Extra-thick retaining rings offer several features that aid in mounting high-curvature optics such as aspheric lenses, short-focal-length plano-convex lenses, and condenser lenses. As shown in the animation to the right, the guide flange of the spanner wrench will collide with the surface of high-curvature lenses when using a standard retaining ring, potentially scratching the optic. This contact also creates a gap between the spanner wrench and retaining ring, preventing the ring from tightening correctly. Extra-thick retaining rings provide the necessary clearance for the spanner wrench to secure the lens without coming into contact with the optic surface.

Thorlabs' uncoated N-BK7 Bi-Convex Lenses are popular for many finite imaging applications. This type of lens is best suited for use in situations where the object and image are on opposite sides of the lens and the ratio of the image and object distances (conjugate ratio) is between 0.2 and 5. These lenses are designed to have a focal length of f= (R1*R2)/((n-1)*(R2-R1)).

Although this page features our uncoated bi-convex lenses, these lenses are also available with one of four antireflection coatings (-A, -AB, -B, or -C) deposited on both sides to reduce the amount of light reflected from each surface. Links to each of these pages can be found in the table to the right. Please see the Graphs tab for coating details.

Ms.Cici

Ms.Cici

8618319014500

8618319014500