Mmdirect, Company and Director Search. - mmdirect

Ball lenscalculator

Ball lenses are a great choice when you want fiber to fiber coupling; coupling light from one fiber optic to another fiber optic that has a very similar numerical aperture. Use two identical ball lenses, and place them at BFL (back focal length) from the fibers.

As described in ASME B46.1, Ra is the arithmetic average of the absolute values of the profile height deviations from the mean line, recorded within the evaluation length. Simply put, Ra is the average of a set of individual measurements of a surfaces peaks and valleys. Reveal the Ra formula for more insight.

Ball lensmicroscope

VIETNAM:Alpha Industrial Park, Tu ThonVillage, Yen My District, HungYen Province 17721+84 221-730-8668sales-vn@avantierinc.com

Ball lensEdmund Optics

Ball lensfocal length

The numerical aperture of a lens depends on the size of the lens (D), the refractive index (n), and the diameter of the source.

Ball lensray diagram

Miniature Optics: In miniature optics, ball lenses are used in devices such as endoscopes, microscopes, and barcode scanners. Their small size and high precision make them ideal for applications where space is limited, and high optical performance is required.

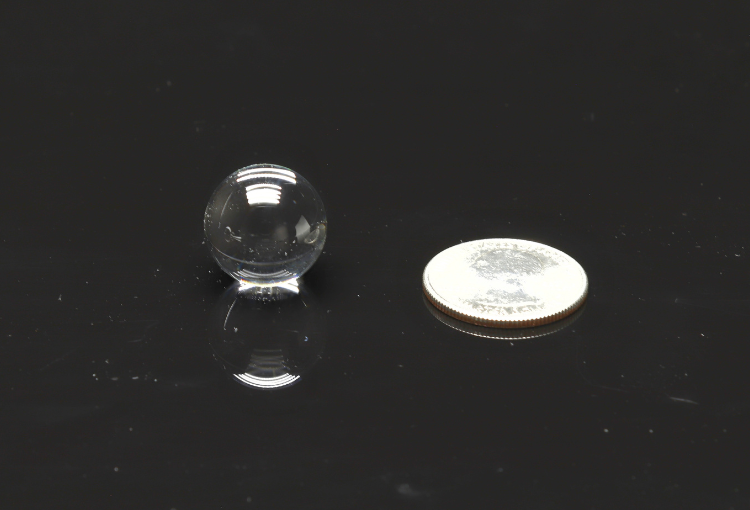

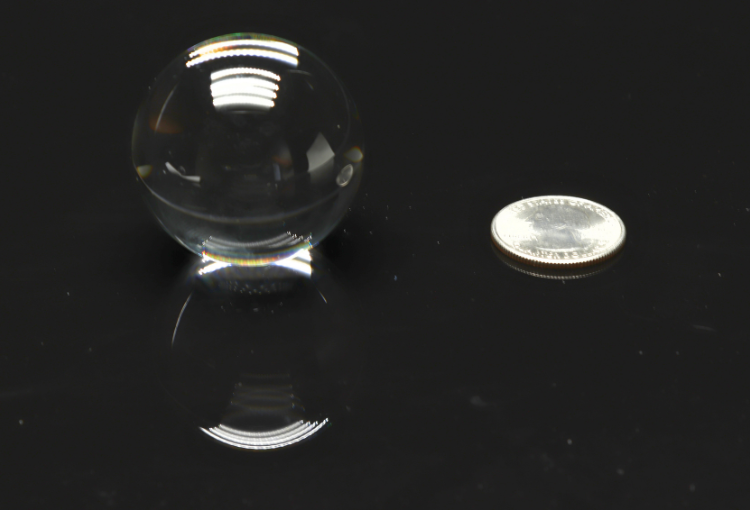

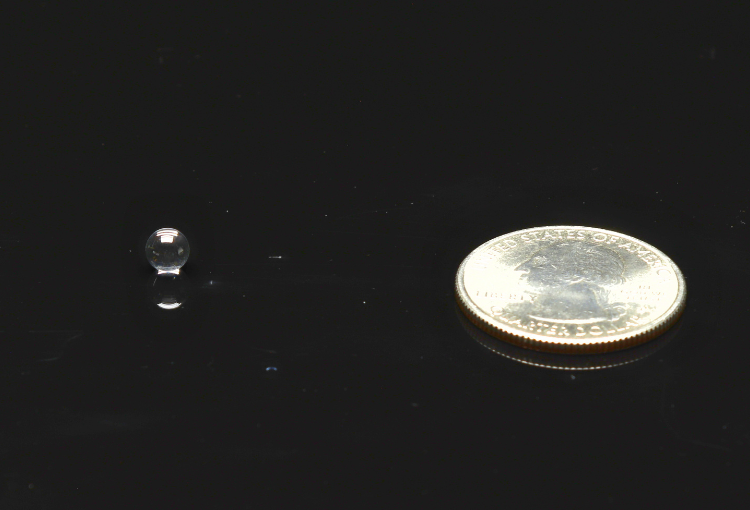

Ball lenses are perfectly round optical spheres that consist of just one transparent substrate such as UV grade fused silica, BK7, or sapphire. Shaped like a tiny, precisely made marble, they are equivalent to two Plano-convex lenses separated by a parallel plane. Custom ball lenses are typically quite small, with a diameter of a few mm or less than 1 mm, and are used as beam collimators for optical fibers, for fiber-to-fiber coupling, to improve signal coupling between fibers, emitters, and detectors, and in the miniature optics used for spectroscopy and bar code scanning. They can also be used as objective lenses for specialty microscopes.

Ra and RMS are both representations of surface roughness, but each is calculated differently. Ra is calculated as the Roughness Average of a surfaces measured microscopic peaks and valleys. RMS is calculated as the Root Mean Square of a surfaces measured microscopic peaks and valleys. Each value uses the same individual height measurements of the surfaces peaks and valleys, but uses the measurements in a different formula. The formulas are shown below. One can infer from examination of the formulas, that a single large peak or flaw within the microscopic surface texture will effect (raise) the RMS value more than the Ra value.

At Avantier we have the ability to design and manufacture custom ball lenses that fit our client’s exact needs. Whether you are working in fiber optics or hoping to design a micro-optical device such as an endoscope that relies on very tiny components, we’re ready to come alongside you as needed. Please contact us today to schedule an initial consultation or to discuss our manufacturing potential.

Fiber Optics: Ball lenses are widely used in fiber optic systems to improve the efficiency of light transmission and signal coupling. They serve as beam collimators, focusing the light from the fiber to a parallel beam, which is crucial for long-distance signal transmission and reducing signal loss.

Halfball lensFocal Length

Halfball lens

The above finishes are some of many mechanical finishes which are often used in the metal finishing industry. Both the NiDi No. 9012 and previous revisions of ASME BPE specifications include a list that describes various mechanical surface finishes for stainless steel.

The electropolishing process may improve a surface finish by up to 50%. The electropolishing reaction removes material while it improves surface roughness. Because of the material removal, process runtimes are often limited to maintain dimensional tolerances. Limited runtimes result in real world surface roughness improvements from 10 to 35%. Remember, electropolishing improves a surface on the microscopic level. If a material has a texture or surface scratch, electropolishing will only result in a lustrous texture or lustrous scratch. Mechanical polishing is utilized to remove macroscopic texture or blemishes.

The effective focal length is simply the distance between the beam focus and a plane through the center of the lens. It can be calculated from the diameter and the index of refraction using this simple equation:

Sapphireball lens

The back focal length, on the other hand, is the distance from the focal point to the lens surface. This is always smaller than the effective focal length by the radius of the ball.

As described in ASME B46.1, RMS is the root mean square average of the profile height deviations from the mean line, recorded within the evaluation length. Reveal the RMS formula for more insight.

Specialty Microscopes: Ball lenses serve as objective lenses in specialty microscopes. Their ability to focus light precisely makes them suitable for high-resolution imaging applications.

Ball lenses are also a good option for laser to fiber coupling. Here you’ll want to choose an appropriate size ball after looking at the cross-sectional diameter of the laser beam and calculating the NA of the ball lens in the system. This NA must be less than the NA of the fiber optic, or light will not be fully coupled.

A fifth important parameter related to the environment rather than the ball itself is the diameter of the input source, (d). It is important to note that every ball lens will exhibit spherical aberrations, and these may become significant when working with small ball lenses where the diameter of the incident beam is scarcely smaller than the diameter of the ball itself. Because of this, you should not expect to attain your theoretical minimum spot size of focus. If these aberrations are not acceptable aspheric lenses can be used instead of optical glass balls.

There are four important parameters to keep in mind when working with ball lenses. These include the diameter of the ball lens (D), the effective focal length (EFL), the back focal length (BFL), and the index of refraction (n).

Ms.Cici

Ms.Cici

8618319014500

8618319014500