Microscopy Basics | Numerical Aperture and Resolution - objective power

450nm LaserSafety Glasses

MXPLFLN objectives add depth to the MPLFLN series for epi-illumination imaging by offering a simultaneously improved numerical aperture and working distance.

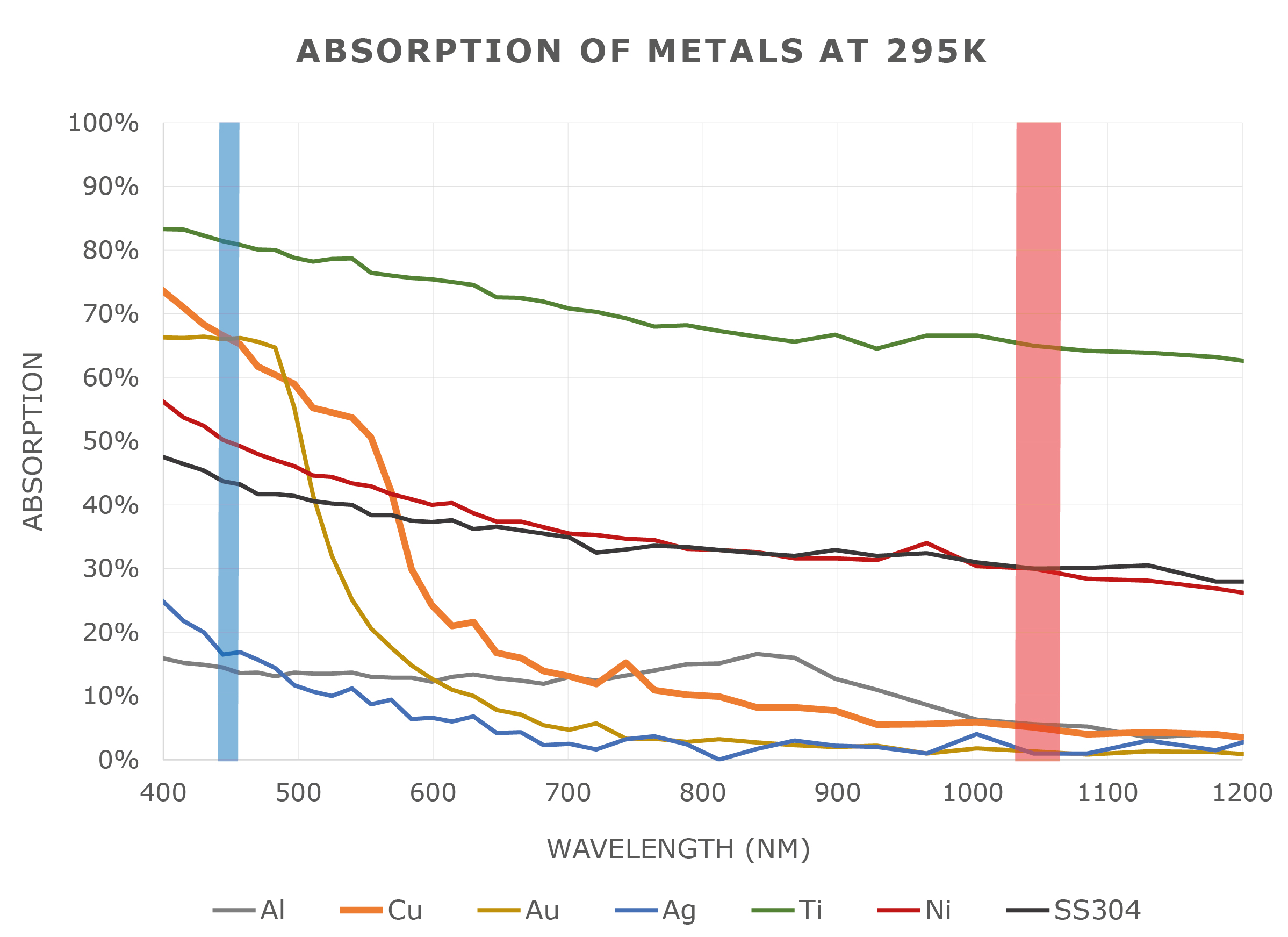

A revolution in material processing: the spatter-free blue diode Laser. Especially for Non-ferrous metals (copper laser welding, gold laser welding).

450nm Lasercolor

Ces cookies collectent des informations sur le comportement de navigation de l'utilisateur dans la boutique sous forme anonyme afin d'obtenir des rapports sur les intérêts de l'utilisateur pour les produits ou services proposés par la boutique.

The advantages of the blue wavelength are especially the spatter-free welding of copper and dissimilar metals (Cu, SS, Al, Ni).

A revolution in material processing: the spatter-free blue diode Laser. Especially for Non-ferrous metals (copper laser welding, gold laser welding).

450nmlight

The application-oriented platform of blue high-power lasers will be changing the metal welding of non-ferrous metals, as well as the additive manufacturing production decisively.

Objective lenses are responsible for primary image formation, determining the quality of the image produced and controlling the total magnification and resolution. They can vary greatly in design and quality.

Olympus microscope objective lenses for industrial inspections offer outstanding optical performance from the visible light to near-infrared region. At Evident, we offer an extensive selection of Olympus objectives suited to specific inspection requirements and tasks. Our MXPLFLN-BD objective is designed for darkfield observation and examining scratches on polished surfaces, while our SLMPLN objective is ideal for electronic assembly inspection. Find your ideal microscope objective today for your inspection task. No matter your requirements, Olympus objective lenses have you covered.

The 450 nm laser AO-200 is a water cooled diode laser with 200 W output power. The diodes are coupled into a 200µm fiber with a QBH termination. The laser operates in cw mode and can also be modulated with up to 50 kHz. It is particularly suitable for copper welding with lasers, for example in battery production.

The ocular lens is located at the top of the eyepiece tube where you position your eye during observation, while the objective lens is located closer to the sample. The ocular lens generally has a low magnification but works in combination with the objective lens to achieve greater magnification power. It magnifies the magnified image already captured by the objective lens. While the ocular lens focuses purely on magnification, the objective lens performs other functions, such as controlling the overall quality and clarity of the microscope image.

Many microscopes have several objective lenses that you can rotate to view the specimen at varying magnification powers. Usually, you will find multiple objective lenes on a microscope, consisting of 1.25X to 150X.

Les cookies de préférence enregistrent des informations spécifiques à l'utilisateur et permettent d'adapter le site web à l'utilisateur, par exemple à la langue ou à la région qu'il a choisie.

To clean a microscope objective lens, first remove the objective lens and place it on a flat surface with the front lens facing up. Use a blower to remove any particles without touching the lens. Then fold a piece of lens paper into a narrow triangular shape. Moisten the pointed end of the paper with small amount of lens cleaner and place it on the lens. Wipe the lens in a spiral cleaning motion starting from the lens’ center to the edge. Check your work for any remaining residue with an eyepiece or loupe. If needed, repeat this wiping process with a new lens paper until the lens is clean. Important: never wipe a dry lens, and avoid using abrasive or lint cloths and facial or lab tissues. Doing so can scratch the lens surface. Find more tips on objective lens cleaning in our blog post, 6 Tips to Properly Clean Immersion Oil off Your Objectives.

MicrometerThis product may not be available in your area.View ProductMPLAPON Our MPLAPON plan apochromat objective lens series provides our highest level of chromatic correction and resolution capability, along with a high level of wavefront aberration correction. View ProductMPLAPON-Oil Our MPLAPON-Oil objective is a plan apochromat and oil immersion lens that provides our highest level of chromatic correction and resolution capability. The numerical aperture of 1.45 offers outstanding image resolution. View ProductMXPLFLN MXPLFLN objectives add depth to the MPLFLN series for epi-illumination imaging by offering a simultaneously improved numerical aperture and working distance. View ProductMXPLFLN-BD MXPLFLN-BD objective lenses add depth to the MPLFLN series for epi-illumination imaging by offering simultaneously improved numerical aperture and working distance. View ProductMPLN Our MPLN plan achromat lens series is dedicated to brightfield observation and provides excellent contrast and optimal flatness throughout the field of view. View ProductMPLN-BD Our MPLN plan achromat lens series is designed for both brightfield and darkfield observation and provides excellent contrast and optimal flatness throughout the field of view. View ProductMPLFLN The MPLFLN objective lens has well-balanced performance with a semi-apochromat color correction, a fair working distance, and a high numerical aperture. It is suitable for a wide range of applications. View ProductMPLFLN-BD The MPLFLN-BD objective lens has semi-apochromat color correction and suits a wide range of industrial inspection applications. It is specially designed for darkfield observation and examining scratches or etchings on polished surfaces. View ProductLMPLFLN Our LMPLFLN lens is part of our plan semi-apochromat series, providing longer working distances for added sample safety and observation with increased contrast. View ProductLMPLFLN-BD Our LMPLFLN-BD brightfield/darkfield objective lens is part of our plan semi-apochromat series, providing longer working distances for added sample safety and observation with increased contrast. View ProductSLMPLN The SLMPLN plan achromat objective lens offers an exceptionally long working distance and the image clarity that you expect from the Olympus UIS2 optical system. It is ideal for electronic assembly inspection and other similar applications. View ProductLCPLFLN-LCD The LCPLFLN-LCD objective lenses are optimal for observing samples through glass substrates, such as LCD panels. The adoption of optical correction rings enables aberration correction according to glass thickness. View ProductLMPLN-IR/LCPLN-IR Our LMPLN-IR and LCPLN-IR plan achromat lenses have a long working distance and are specifically designed for optimal transmission in the near-infrared region (700–1300 nm wavelengths). View ProductWhite Light Interferometry Objective Lens This objective lens is designed for the Mirau style of white light interferometers and maintains a high level of temperature tolerance. The optimized numerical aperture of 0.8 provides improved light gathering, with a working distance of 0.7 mm. View Product

Le site Web de Laser 2000 utilise des cookies pour améliorer et étendre continuellement les fonctions et le contenu de notre site. Cliquez sur "Accepter tout" pour bénéficier d'une expérience utilisateur complète ou sélectionnez individuellement les cookies que vous souhaitez utiliser. Si vous cliquez sur le bouton "Plus d'informations", vous obtiendrez plus de détails sur la politique de protection des données de Laser 2000.

MXPLFLN-BD objective lenses add depth to the MPLFLN series for epi-illumination imaging by offering simultaneously improved numerical aperture and working distance.

Terms Of Use | Privacy Notice | Cookies | Cookie Settings | About Us | Imprint | Careers | Careers | Sitemap

Terms Of Use | Privacy Notice | Cookies | Cookie Settings | About Us | Careers | Careers | Sitemap

A revolution in material processing: the spatter-free blue diode Laser. Especially for Non-ferrous metals (copper laser welding, gold laser welding).

The new generation of blue laser diodes was developed for micro and macro material processing of copper and its alloys as well as for nobel metals. Several high reflective metals have a limited absorbtion in the IR and the green wavelength. In this spectral width the blue wavelength has significant advantages. In a microscopic and macroscopic inspection of the welding spot the homogeneous liquid phase of the weld pool shows a more wax-like behaviour than the common well known one of metals.

Les cookies marketing enregistrent des informations sur les autres sites web visités. Ces cookies sont utilisés pour afficher des publicités adaptées à l'utilisateur et sont donc pertinents pour les éditeurs et les annonceurs externes (tiers).

Les cookies nécessaires sont indispensables pour permettre des fonctions de base telles que la navigation sur le site ou l'accès à des zones protégées du site. Sans ces cookies, le site web ne peut pas être utilisé comme prévu.

Ms.Cici

Ms.Cici

8618319014500

8618319014500