Metaphase Technologies Inc. Information - metaphase technologies

UVcuring lamp automotive

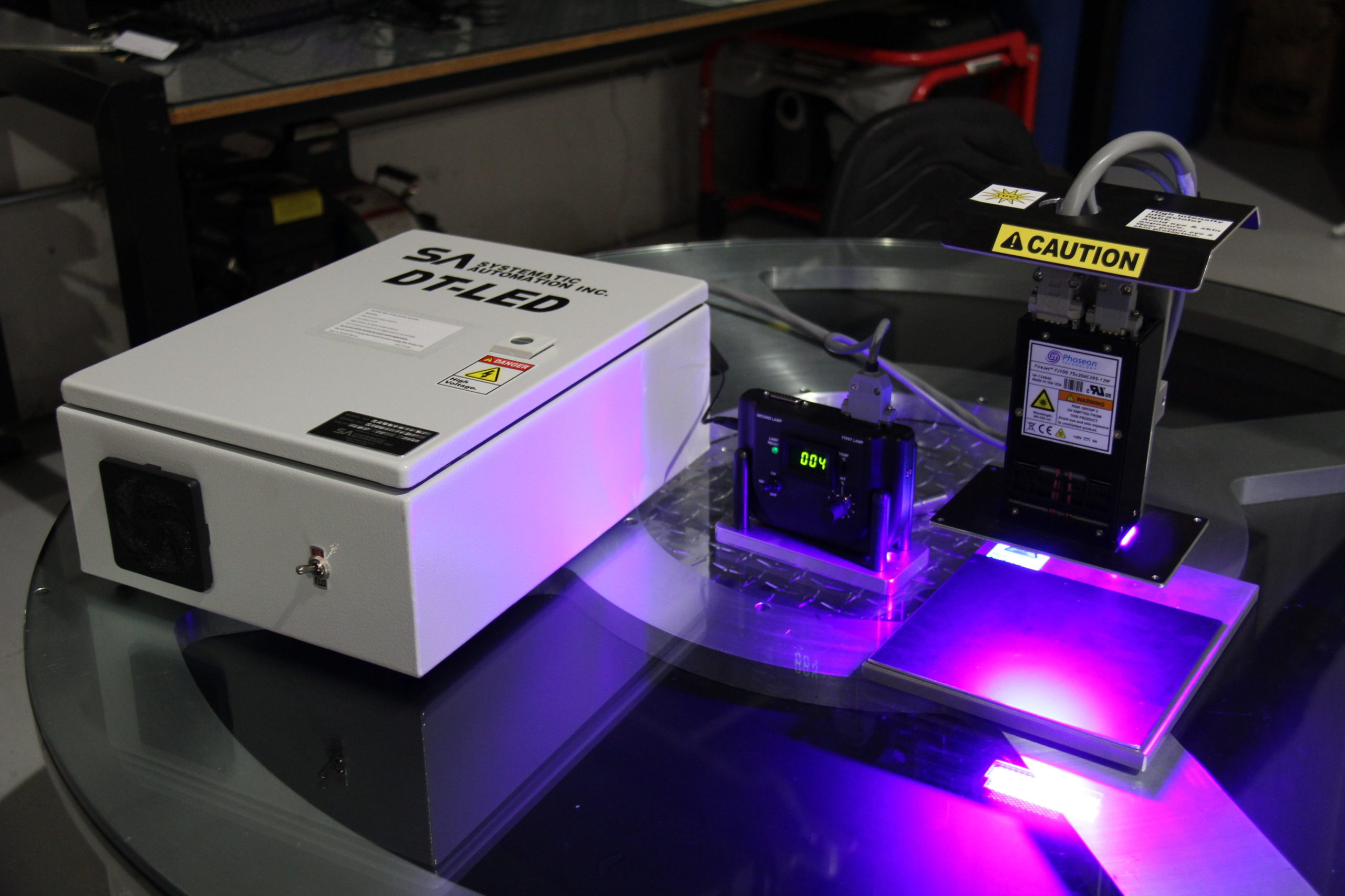

There is still work to be done on the technology that will enable UV LEDs to be widely used in the UV curing industry, but even today operators can see benefits in using LED over traditional UV lamps because:

"We were new to screen printing and Systematic Automation helped us from the beginning of what inks to choose, making our screens and training us on screen printing. We still call for assistance now and then and are met with immediate support."

UV curing is a photochemical process that instantly cures inks, coatings, or adhesives using UltraViolet light. Liquid monomers and oligomers are mixed with a small percentage of photoinitiators and then exposed to UV energy. After a few seconds, the formulation hardens or cures, ready for further processing.

"Our production has nearly doubled from switching over from our previous printing machine. SA has integrated features into the printing process to make it effortless for the operator."

Card Text: oX, ocT: Target spell, which targets you, targets the player of your choice instead. X is twice the casting cost of target spell. This ability is ...

Low Voltage: A lamp's running voltage will decrease over time. When the lamp voltage drops below the recommendation set by the Voltage Relay, the lamp will not send a "Lamp ready" signal to the press. If this happens, change your light immediately.

The Customizable Brilliance of Adjustable LED Wall Lights. One of the foremost benefits of adjustable LED wall lights lies in their capacity for customized ...

UVCuringlightfor resin

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

A UV lamp can also undergo devitrification if chemical impurities on its body, such as oil secreted by the skin, catalyze the process. Our recommendation is:

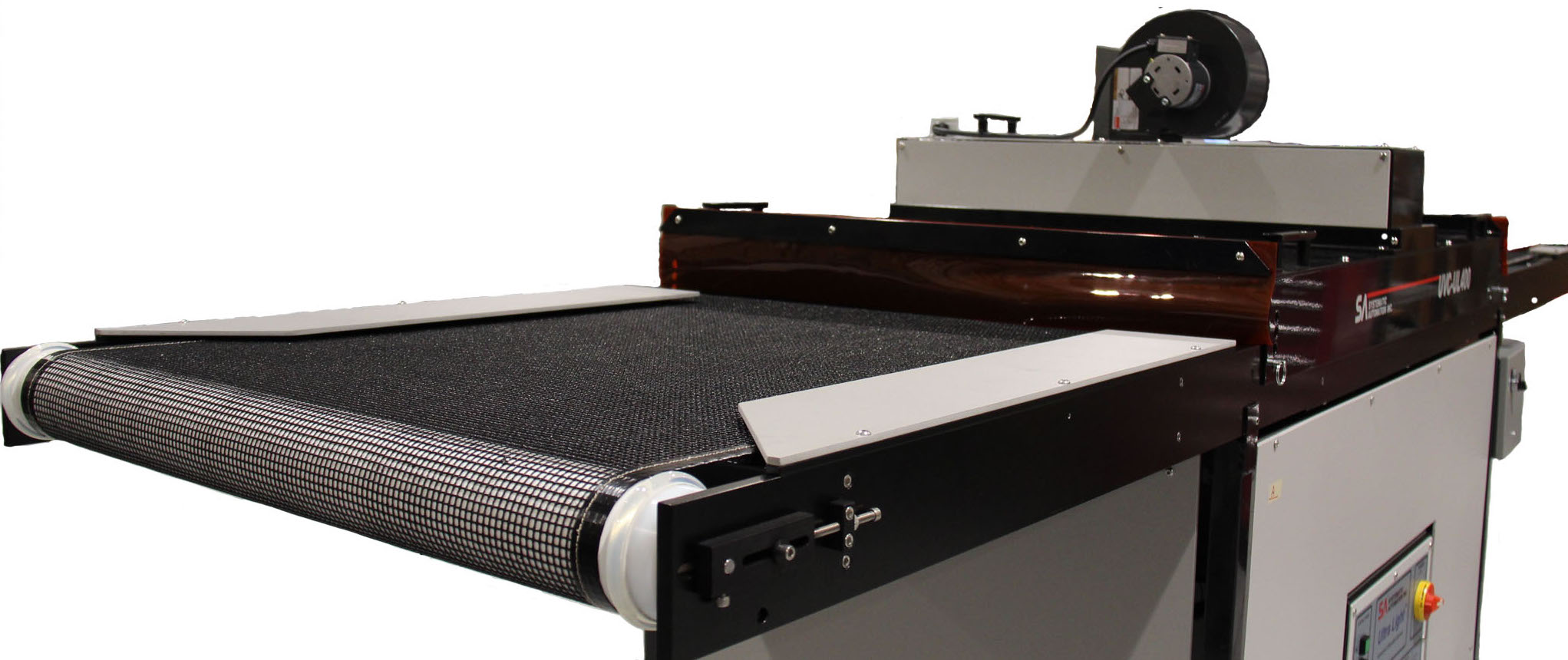

The UV curing process can be used to cure UV inks, adhesives, and resins. One of the greatest advantages of UV inks is that they stay liquid as long as they are not exposed to UV light and cure almost immediately, allowing greater freedom for the operator. For printers with consistent orders and a desire to increase production throughput, UV inks are an excellent choice.

Custom Video Security carries affordable customized DVR and IP Video Surveillance Systems and Access Control, as well as a wide range of ...

"I was starting my business and completely lost. Systematic Automation helped every step along the way and encouraged questions."

UV Curing is a special curing process that utilizes UV lamps to create a chemical reaction or physical action that takes place, resulting in a harder, tougher or more stable linkage or substance.

The UV inks are not as resilient as the solvent based inks. In the event the product will be used repeatedly, Systematic Automation heavily recommends pretreatment, which can range from flame, plasma and Fierosil. To determine if you need to pretreat an item, you can conduct a dyne test or a cross scratch test.

Adhesives and sealants are formatted in either epoxy or acrylate forms. Applications using plastics, rubbers, glass, metal and ceramics rely on adhesives and sealants. Adhesives offer bonding that is not visible. Sealants cure and form in place. Conformal coatings (layer of protection for circuit boards) and encapsulants (electrical insulation) are applications that typically use UV curing.

Shop for Giant Magnifying Glass - Black at wilko - where we offer a range of home and leisure goods at great prices.

BestUV lightfor curing resin

In recent decades, UV curing technology has grown rapidly. The instant curing technology that revolutionized printing has now spread to other industries and technologies due to its ability to be processed and packaged within seconds of exposure.

All Content Copyright 2012 - GT Engineering Supplies. All Rights Reserved Website designed by Cornerstone Design & Marketing

UVcuring Lamp for paint

"We were confused of where to go for our application. Systematic Automation was the right choice. Not only did they make tooling specific for our product but they gave excellent advice for printing that saved us thousands."

Dyne Test: You will need a dyne kit with droppers in order to perform this test. With the test you will be able to determine if you have a good dyne level if the liquid maintains its state. If your dyne level is less than optimal, liquid will bead out and not leave the full liquid line on your cup.

Plastic Windows for Displays ... Parker's plastic window offerings serve as resistive and projective capacitive surfaces for LCD touchscreens, providing ...

Uv cure lightnails

Reflectors are extremely important, generating around 70% of the usable UV, so they should be checked and maintained regularly. Reflectors should be replaced whenever the lamp is changed, or sooner if they are dirty or damaged.

NOTE: If left out, the UV from your factory lights can partially dry the ink. For UV ink printers, we recommend covering the machine so no light can pass through if you wish to leave the ink on the screen overnight or over a break.

A high quality cable, rated at 20 KVA, is used in all high voltage cables manufactured by Systematic Automation and can be supplied to users for any additional connections that may be required.

99% of failures are misdiagnosed as lamp failures. Most often, these are actually failures caused by other components such as capacitors, ballasts, reflectors, or ignitors. However, there are some standard signs that will alert you when a lamp replacement is necessary. There are two issues that will demand immediate replacement: a lamp with depleted running voltage, and a lamp that is swollen.

Here we define Field of View (FOV) by detector size and microscope objective, and Field of Illumination (FOI) relative to the detector and in the image ...

GT Engineering Supplies Unit A1, Falcon Business Centre, Victoria Street, Chadderton, Oldham, Lancashire, OL9 0HB Tel: +44(0)161 678 8841 Email: info@gtengineeringltd.co.uk

"Taking our printing process in house was the best decision we could have made. Orders are much more profitable and the Model F1 is so simple to work with that we are introducing new products."

Uv cure lightreviews

Traditionally, UV curing is done using lamps that cover a wide spectrum of wavelengths. This UV system comes with a series of advantages that make it the ideal choice amongst operators, such as:

Edmund Optics USAF 1951 Resolution Target.

Ozone is a gaseous form of oxygen which is formed by ultraviolet light generated from arc type UV lamps (not LED lamps which generate no ozone). It’s characteristic odor is readily detectable at low concentrations (0.02 to .05 parts per million). Excessive exposure to ozone produces local irritation of the eyes and of the respiratory tract. It can be dangerous at higher than acceptable levels in the workplace. Be sure your equipment has adequate ventilation. Do not use your equipment in a confined space. Maintain work area ozone levels below the OSHA permissible exposure limits of 0.1 part of ozone per million (ppm) of air in an 8-hour time weighted average. Maintain a healthy work area by monitoring ozone levels using detecting instruments such as the EZ-1X device available from Ozone Solutions.

"Our experience with manufacturers of printing equipment was lacking in communication and quality. Systematic Automation worked with us on automating our printing process, manufacturing custom unloading, and loading systems to work with our assembly line."

Surface temperature of the lamp during normal operation will exceed 800 degrees Fahrenheit. Before attempting service procedures on the lamp, allow the unit to cool. Observe appropriate precautions to avoid burns. Handle the bulb with cotton or surgical gloves or a lint-free towel at all times, as fingerprints can be etched into the quartz.

Cross Scratch Test: A cross scratch test is simple, and only requires a blade. You will know an image will not stand the test of time if a blade is pressed against it and scratches it off. You might even be able to remove the ink using your fingernail.

Click here for a material safety data sheet (MSDS) on ozone. Contact your State OSHA office for compliance assistance. Contact Systematic Automation service department (860) 677-6400 ext.117 for assistance on how to provide adequate ventilation for your particular machine model. Ozone free lamps are available from Systematic Automation. These type of lamps may not be appropriate for your particular application. Call our service department for information on ozone free lamps.

An iron lamp will significantly increase intensity. Nanometer ranges are available on our website under UV and lamps. Iron spikes in the 395 nm range. Gallium additive is also available with a peak in the 410 nm range. Your ink supplier will verify if this will be more effective. If so, we recommend you try out an iron lamp and raise the lamp an inch or more. By raising it, you will allow more of the light emanating from the center of the lamp to reach to outside of the material being printed. Iron lamps and additive lamps in our experience are harder to start (they may need to be fully cool to start and may require more than one attempt). They also have a shorter life.

Ultraviolet radiation can be dangerous to the eyes and skin of personnel. Adequate shielding blocking UV light exposure must be provided. If unsafe levels of light are allowed to escape during operation, all personnel in the vicinity of the system should be required to wear goggles with UV certified lenses. Protection is needed for indirect as well as direct eye exposure. Discomfort from excessive eye exposure to ultraviolet light typically occurs about six hours after exposure. Personnel who experience eye pain after possible exposure to direct rays from the UV lamp should see a doctor. Furthermore, in the event that adequate shielding is not possible, all personnel within ten feet of the lamp should wear gloves and a long-sleeved shirt to protect their hands and arms.

There are no present U.S. Government standards on worker exposure to ultraviolet light. However, there is a NIOSH document, “Criteria for a recommended standard… Occupational Exposure to Ultraviolet Radiation” (No. HSM 73-11009), and several useful publications are available from the Bureau of Radiation of the Food and Drug Administration.

Uv cure lightamazon

Great customer service is part of our culture here at Systematic Automation. We’re ready and happy to help you with your questions, and assist you in selecting the right machine for your specific application. We’re also happy to provide you with a customized quote. Just get in touch - we’d love to hear from you.

Share your fave moment from BG3! It could ... magnifying glass". So I apologize for ... Some bg3 themed metalwork. The pendants are ...

Systematic Automation offers UV curing solutions for your application and budget. Contact us to learn more about the best options for your business.

Insulated electrical cables carry high power from the power supply to the lamp. These voltages can be dangerous. Precautions should be taken in both the location and protection of these lines.

Gausah kesel didatengin orang-orang pas mereka butuh doang. Berarti di mata mereka we're capable and kind enough to help others, which means, we're successfull ...

Wait for lamps to cool before restarting. When a lamp is turned off, ions and electrons recombine and charge carriers are lost. In contrast, when the lamp is still hot, the atoms in the lamp move quickly and this leads to a high resistance when the lamp is restarted.

Allen Keys are available in Long / Short Arm & Tee Key Type and also available as Hexagon Drive Bits for use with Cordless Drill Drivers & Various Hand Tools.

Uv cure lightnear me

Keeping your UV lamp clean can help prevent problems like devitrification that can occur when it becomes overheated after surface contamination. Natural "devitrification" occurs when quartz converts back into a crystalline structure, which is a very poor UV transmitter. As a result of devitrification, quartz becomes less transparent to UV light, with many white spots on the surface. Once this occurs the lamp will become very poor at transmitting UV. The different density causes micro cracks in the body of the lamp and loss of vacuum power, which will lead to lamp failure. UV lamps may need to be replaced once devitrification begins.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Why do phone cameras have to reduce resolution in order to create high FPS video? Pretty much all cameras do, though the specifics depend on ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500