Magnifying Glass | Toys R Us Canada - where to buy a magnifying glass near me

Topoptics companies

These are used to selectively transmit or reject a wavelength or range of wavelengths. Filters are used in spectroscopy, clinical chemistry, machine vision inspection, and more.

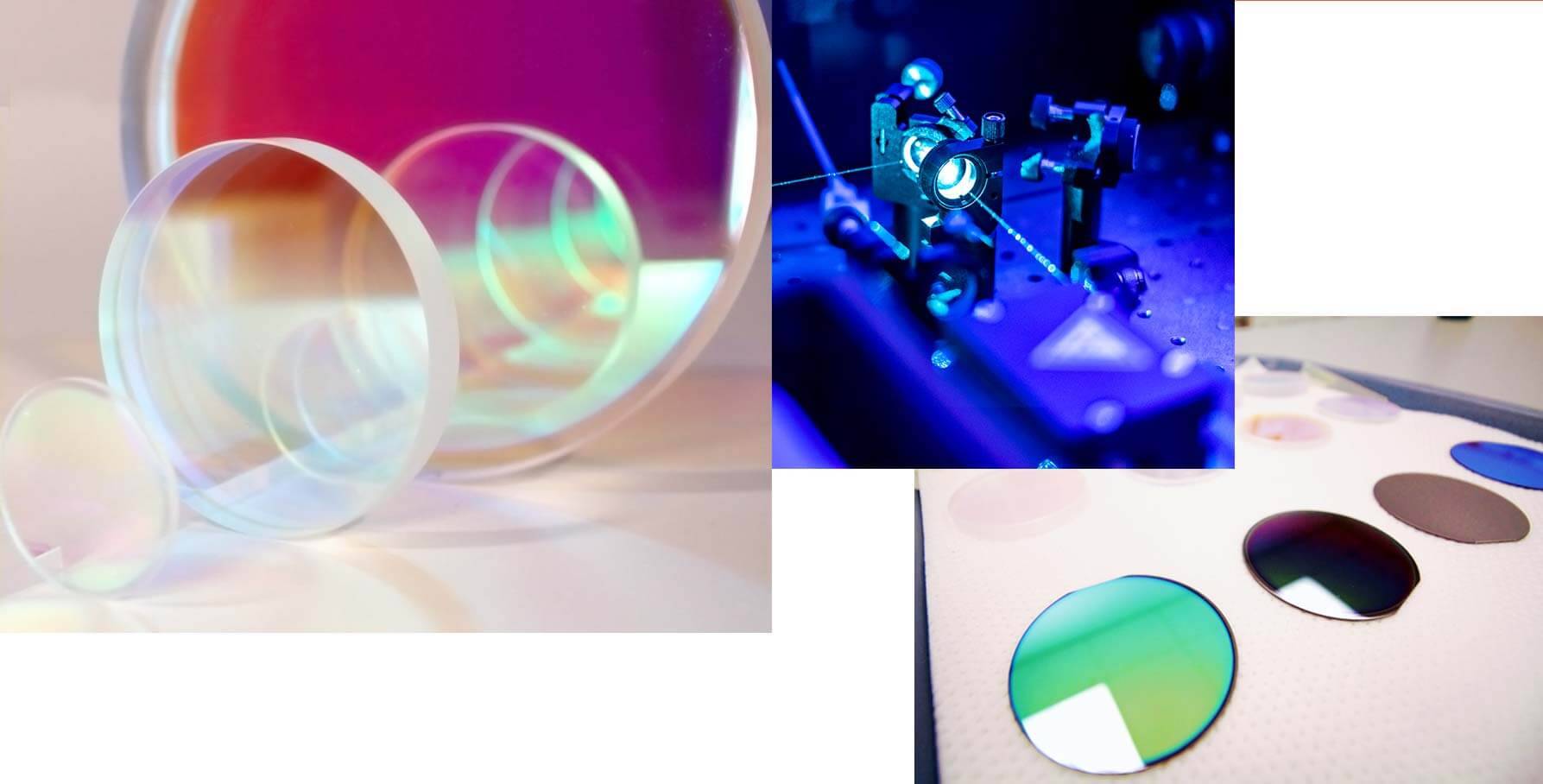

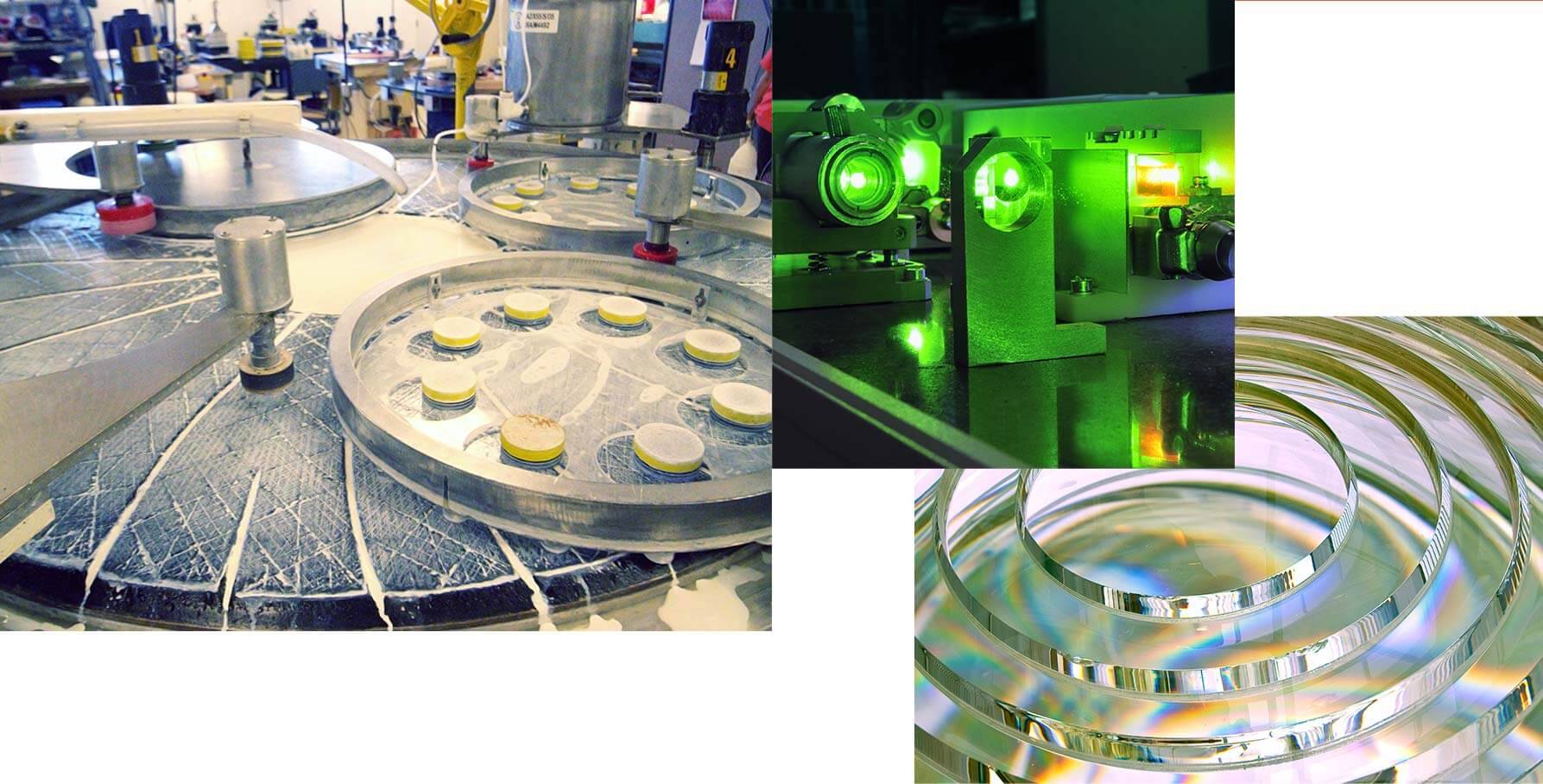

We use the highest quality materials and advanced optical engineering techniques to create custom and laser optic solutions. From fabrication to polishing, our precision optics manufacturing company readily produces custom precision optics, either off-the-shelf, engineered to your needs, or modified stock research products. We have over 30 years of experience manufacturing optics and supplying them across industries. An alpine research optical company is one of the best precision optical manufacturing companies in United States. Our facility offers many optic products such as co2 lenses, windows, optical components, optical filters, prisms and more. Check out our selection below.

Thorlabs

A.R.O. supplies OEM engineering and subassemblies to manufacturers of lasers, laser-based systems, and instruments in a broad range of demanding industries. With our in-house polishing equipment, coating chambers and state-of-the-art metrology, we guarantee parts are made to the top standards from start to finish.

OpticsPlanet

The LibreTexts libraries are Powered by NICE CXone Expert and are supported by the Department of Education Open Textbook Pilot Project, the UC Davis Office of the Provost, the UC Davis Library, the California State University Affordable Learning Solutions Program, and Merlot. We also acknowledge previous National Science Foundation support under grant numbers 1246120, 1525057, and 1413739. Legal. Accessibility Statement For more information contact us at info@libretexts.org.

Lasers use these design research optics and laser technology with short pulse durations on the order of picoseconds, femtoseconds, or attoseconds.

At very high magnifications with transmitted light, point objects are seen as fuzzy discs surrounded by diffraction rings. These are called Airy disks. The resolving power of a microscope is taken as the ability to distinguish between two closely spaced Airy disks (or, in other words, the ability of the microscope to distinctly reveal adjacent structural detail). It is this effect of diffraction that limits a microscope’s ability to resolve fine details. The extent and magnitude of the diffraction patterns are affected by the wavelength of light (λ), the refractive materials used to manufacture the objective lens, and the numerical aperture (NA) of the objective lens. There is therefore a finite limit beyond which it is impossible to resolve separate points in the objective field. This is known as the diffraction limit.

Elite100

EdmundOptics

Optical lenses are components designed to focus or diverge light. They may consist of a single or multiple elements. Optical lens are used from medical to laser processing industries.

Flat, plane-parallel plates that are often used as protective barriers for electronic sensors or detectors from outside environments.

Opticsstartups

Our core strength is our ability to produce durable, long life, high damage threshold coatings on tight tolerance substrates, particularly in the UV. We support a wide variety of laser applications for leading edge equipment manufacturers in the semiconductor, medical, defense, industrial markets. We are also very proud to have many of the world renowned universities and national laboratories as permanent customers.

Our in-house capabilities have expanded from the UV to the NIR spectrum and fabrication of spherical and flat items with complex shapes. Our employees work tenaciously to offer reliable precision optics engineering and remarkably consistent on-time deliveries.

Resolution depends on the distance between two distinguishable radiating points. A microscopic imaging system may have many individual components, including a lens and recording and display components. Each of these contributes to the optical resolution of the system, as will the environment in which the imaging is performed. Real optical systems are complex, and practical difficulties often increase the distance between distinguishable point sources.

RifleOptics companies

This page titled 3.1D: Magnification and Resolution is shared under a CC BY-SA 4.0 license and was authored, remixed, and/or curated by Boundless via source content that was edited to the style and standards of the LibreTexts platform.

Optical beamsplitters are used to split input light into two separate parts. Polarizing beam splitter cube or plate is common in illumination systems.

Magnification is the process of enlarging something only in appearance, not in physical size. This enlargement is quantified by a calculated number also called “magnification. ” The term magnification is often confused with the term “resolution,” which describes the ability of an imaging system to show detail in the object that is being imaged. While high magnification without high resolution may make very small microbes visible, it will not allow the observer to distinguishbetween microbes or sub-cellular parts of a microbe. In reality, therefore, microbiologists depend more on resolution, as they want to be able to determine differences between microbes or parts of microbes. However, to be able to distinguish between two objects under a microscope, a viewer must first magnify to a point at which resolution becomes relevant.

Ms.Cici

Ms.Cici

8618319014500

8618319014500