Infrared Optics FAQ - optical infrared

The application of AR coatings is a complex, high-tech process that requires precision and cleanliness. The process is typically conducted in a vacuum chamber to ensure the purity and adherence of the coatings. Here’s a step-by-step overview:

where n is the refractive index and equal to 1 for air and α is the half angle subtended by rays entering the objective lens.

anti-reflective glass coatingspray on

Cambridge Isotope Laboratories, Inc. (CIL) offers product WG-806-A-Q Suprasil tissue cell.

The numerical aperture of a microscope objective is a measure of its ability to resolve fine specimen detail. The value for the numerical aperture is given by,

Bestanti reflective coating for glass

Optical Cast Infrared (IR) Longpass Filters ideal for blocking visible light, while passing near infrared wavelengths are available at Edmund Optics.

2004-2024 University of Cambridge. Except where otherwise noted, content is licensed under aCreative Commons Attribution - NonCommercial-ShareAlike 4.0 International.

where 2α is the angle through which the first-order beam is diffracted. Since the two beams are just collected by the objective, i = α, thus the limit of resolution is,

non-reflectiveglass forframing pictures

Oleophobic coatings, on the other hand, are designed to repel oils. This includes the natural oils from a person's skin, which can be transferred to the lenses during handling. By repelling these oils, oleophobic coatings help to keep lenses free from smudges and fingerprints. This property is especially valuable for individuals who frequently need to adjust or touch their glasses. The reduced adherence of oils and other substances also makes the lenses easier to clean and maintain, contributing to better lens hygiene.

The limit of resolution (or resolving power) is a measure of the ability of the objective lens to separate in the image adjacent details that are present in the object. It is the distance between two points in the object that are just resolved in the image. The resolving power of an optical system is ultimately limited by diffraction by the aperture. Thus an optical system cannot form a perfect image of a point.

Improves Visual Clarity: With an anti-reflective coating, a greater amount of ambient light can reach your eyes, unobstructed by lens reflections. This optimized light transmission results in clearer, more acute vision, allowing you to perceive your surroundings with enhanced sharpness and detail.

Anti reflective coating forglasses DIY

Modulation Transfer Function (MTF) stands as a pivotal metric in optics and image quality assessment. It provides a comprehensive evaluation of a lens system's ...

The wavelength of light is an important factor in the resolution of a microscope. Shorter wavelengths yield higher resolution. The greatest resolving power in optical microscopy requires near-ultraviolet light, the shortest effective visible imaging wavelength.

Laser pointing accuracy and pointing stability are defined as an angular value, usually in milli- or microradians (mr or μr). Pointing accuracy is simply ...

Hydrophobic coatings, as the name suggests, repel water. This means that when water comes into contact with a lens equipped with a hydrophobic coating, it beads up and rolls off rather than spreading and smearing. This characteristic is particularly beneficial in rainy conditions or during activities that involve water, such as boating or fishing. It ensures that the wearer's vision remains unobstructed by water droplets. Additionally, the hydrophobic properties help to prevent fogging, a common issue in humid environments or when moving between different temperatures.

For resolution to occur, at least the direct beam and the first-order diffracted beam must be collected by the objective. If the lens aperture is too small, only the direct beam is collected and the resolution is lost.

Anti reflective glassprice

Numerical aperture determines the resolving power of an objective, the higher the numerical aperture of the system, the better the resolution.

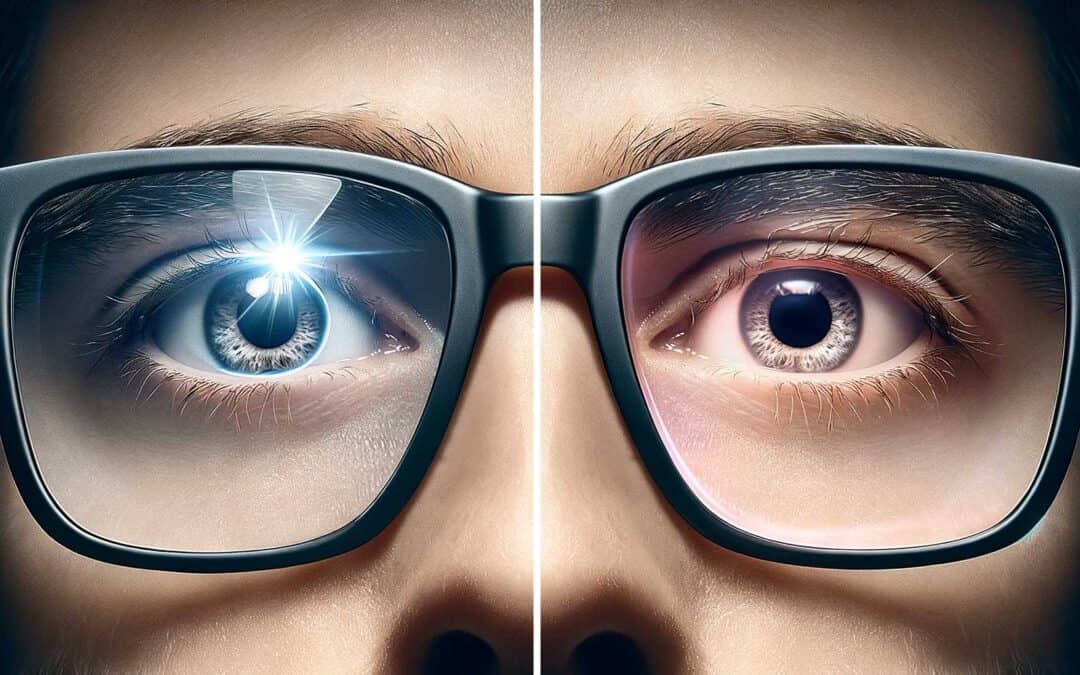

Light coming from the back of the wearer to the back surface of a lens will also undergo a certain amount of reflection. Light here can be reflected directly back to the eye. The results can be a distraction to the wearer or can, in certain conditions, impair vision. For example, bright sun light hitting the back surface of a sun lens that is not AR coated, depending on the angle, can either be reflected directly back into the eye or can "fill" the lens with reflected light. Either case can result in significant vision impairment.

The field of view is largest on the lowest power objective. When you switch to a higher power, the field of view closes in towards the center. You will see more ...

Hydrophobic and oleophobic coatings are significant enhancements often applied in conjunction with Anti-Reflective (AR) coatings on eyeglass lenses. These coatings play a vital role in maintaining the clarity and longevity of the lenses, further enhancing the wearer's visual experience.

The primary minimum sets a limit to the useful magnification of the objective lens. A point source of light produced by the lens is always seen as a central spot, and second and higher order maxima, which is only avoided if the lens is of infinite diameter. Two objects separated by a distance less than θR cannot be resolved.

Sep 17, 2013 — My Mk1 one was from custom cages. OK to deal with, profiles on the tubes way off in some places though. Ended up sorting it all myself anyway, ...

To polarize is to divide. Something that's been polarized has been split into two sides that are so different, it seems as though they're from opposite ends of ...

Anti reflective coating for glassdoor

The beam angle of the Fresnel lenses ranges from 10 to 45 degrees. Like the spotlights with COB LED, the Theatre Spot – as its name suggests – is particularly ...

AR coating can minimize front and back lens surface reflections, significantly reducing or eliminating the problems discussed above, reducing eye strain, while allowing more light to reach the eye, improving contrast and clarity.

When combined with AR coatings, hydrophobic and oleophobic coatings contribute to a superior lens performance. AR coatings alone significantly reduce reflections and improve visual clarity, but they can sometimes be prone to smudges and moisture. The addition of hydrophobic and oleophobic properties ensures that the AR coating can function optimally by keeping the lens surface clear and clean. This combination results in a lens that not only provides sharp, clear vision through reduced glare but also remains cleaner and clearer during everyday use, enhancing the overall satisfaction and experience of the eyewear.

Antireflectioncoatingformula

anti-reflective coating for glasswindows

When light from the various points of a specimen passes through the objective and an image is created, the various points in the specimen appear as small patterns in the image. These are known as Airy discs. The phenomenon is caused by diffraction of light as it passes through the circular aperture of the objective.

The limit at which two Airy discs can be resolved into separate entities is often called the Rayleigh criterion. This is when the first diffraction minimum of the image of one source point coincides with the maximum of another.

AR coating is a thin, multilayered application on eyeglass lenses designed to reduce reflections, allowing more light to pass through. This improves vision clarity and reduces glare from digital screens and headlights. A thermal cured hard coat, on the other hand, is applied to make lenses more resistant to scratches and impacts, extending their usable life.

AR coatings reduce lens surface reflections through a process called destructive interference, by actually generating reflections of its own. The index of refraction of the AR layer is in between that of the lens medium and that of air. Light incident upon an AR coated lens experiences reflection at both the AR layer and the surface of the lens. However, the thickness of the AR layer is such that the light waves reflected from the AR surface are 180° out of phase with light waves reflected from the surface of the lens. Consequently, the reflected light waves undergo destructive interference and effectively cancel each other.

Crafted from durable metal, this iris diaphragm module ensures longevity and reliability. Its adjustable range from 1.5mm to 23mm allows for precise control ...

Airy discs consist of small, concentric light and dark circles. The smaller the Airy discs projected by an objective in forming the image, the more detail of the specimen is discernible. Objective lenses of higher numerical aperture are capable of producing smaller Airy discs, and therefore can distinguish finer detail in the specimen.

In photographic optics, the term Depth of Focus has two related but different meanings. 1. Depth of Focus (image-side version of depth-of-field) – The ...

Anti-reflective coating becomes even more important when you have a stronger prescription that calls for high-index lenses, which tend to reflect more light than other types of eyeglass lenses.

As light passes through a lens from air, it experiences a change in index of refraction. When that occurs, some of the incident light is transmitted through the lens material and refracted while some of the light is reflected. This reflected light is perceived by others as glare and represents a loss of light transmitted through to the eye.

θR is the angular position of the first order diffraction minimum (the first dark ring) λ is the wavelength of the incident light d is the diameter of the aperture

The science behind AR coatings involves using layers of material with specific refractive indices that work together to cancel out the light reflections. This not only reduces glare but also significantly minimizes eye strain and fatigue associated with prolonged exposure to bright light sources. Additionally, AR coatings make the lenses nearly invisible, thereby improving the cosmetic appearance of the glasses. They also help in reducing the reflections others see on the lens surface, allowing for better eye contact. With these functional and aesthetic benefits, AR coatings have become a popular choice for enhancing the performance and appearance of eyeglasses.

Fun Fact: The Law of Conservation of Energy states that energy can neither be created nor destroyed. So, what happens to the energy from the cancelled light waves? It is transferred through the lens medium to the patient's eyes improving contrast and clarity!

As the refracted light continues through the lens material and reaches the back surface of the lens, there is another index change (lens to air) and again refraction and reflection occur. Reflected light here can bounce off the internal surfaces of the lens and be seen by the wearer as glare, blurred or ghost images. Others may see internal reflections as multiple rings inside the lens (most prevalent in high minus powers). Blurred or ghost images can become intensified at night around bright lights common in dusk or night time driving conditions, and can significantly impair vision. Also, this backside reflection represents further loss of light transmitted through to the eye.

From the equation it can be seen that the radius of the central maximum is directly proportional to λ/d. So, the maximum is more spread out for longer wavelengths and/or smaller apertures.

An Anti-Reflective (AR) coating, also known as anti-glare coating, is a thin multilayer finish applied to the surface of eyeglass lenses. This coating is designed to reduce the amount of surface glare that reflects off the lenses, thereby enhancing the efficiency of the glasses. AR coatings play a pivotal role in improving visual clarity and comfort, especially in situations where the wearer is subjected to bright lights, such as while using digital screens or driving at night.

Ms.Cici

Ms.Cici

8618319014500

8618319014500