HUAWEI MATE 10 Polarisor 10 pcs - polarisor

Low outgassing is another consideration when choosing optical adhesives. This feature is highly desirable in applications involving lenses, semiconductors, optical components, and vacuums. Many epoxies pass the NASA low outgassing test based on the ASTM E-595 standard, which is tested under vacuum conditions. Specific specialty silicones and UV-curable products also pass this stringent test. Military and aerospace applications may impose NASA low outgassing requirements, combining the need for optical transparency with the ability to withstand exposure to harsh environmental conditions and extreme mechanical stress. Adhesives can provide optical systems vital resistance to high-stress events like sudden acceleration, vibration, and mechanical shock.

Aside from spherical and chromatic aberrations, Fresnel lenses also suffer from distorted images. This means the image seen after light passes through the Fresnel lens will not be a perfect replica of the original object. When using a Fresnel lens to magnify text, the letters and words may be harder to distinguish especially at higher magnifications. This trait limits the effectiveness of Fresnel lenses as a tool for magnification. Of course, this has no impact on a bright white light like a lighthouse.

Optical Glue

The right adhesive allows peak performance for laser systems, optical devices, and fiber optics. Be it temperature resistance, stress relief, or protection from moisture or other corrosives, adhesives are critical partners for a wide range of optics and photonics applications.

In general, optical adhesives must work well on diverse substrates, and offer excellent temperature resistance, stress relief, and protection from moisture and other corrosive elements. Systems can be formulated with additional performance properties like high mechanical strength. Handling and processing parameters such as mix ratios, viscosity, working life, and cure time play a vital role in the adhesive selection process.

Though they were originally deigned for use in lighthouses, Fresnel lenses are useful anywhere a concentrated beam of light is needed. Today, many bike lights use a Fresnel lens to increase visibility for a biker and for vehicles around them. Plastic Fresnel lenses provide extra magnification when reading, though there is often distortion, especially near the edges. Examples of Fresnel lenses, available for purchase can be found here.

NorlandOptical Adhesive

Since many applications focus on the visible light wavelength range, they can be made of plastics, which reduce the cost and weight even more. This was first done with a mold, though today there are many techniques for creating structures on material surfaces. This is possible because many plastics are transparent to visible light. However, UV or IR wavelengths requires lenses to be made of a different material.

A one-component, 80-degree C curable, exceptionally low viscosity epoxy for bonding, coating, and sealing is Master Bond’s EP4CL-80. It is clear and is a reliable electrical and thermal insulator.

In other situations—for example, mounting optics on various substrates or sealing—a more moderate viscosity or even a paste is desirable. Ultimately, the choice depends upon a host of factors including dimensions, the nature of the application, how the material will be applied, and what properties are required after cure.

With the need for alternative energy sources, solar energy is gaining a lot of attention. One of the main drawbacks for solar energy is the inefficiency of many solar cells. They are unable to make full use of the solar energy entering our atmosphere. Fresnel lenses offer a solution, by concentrating light at the solar cell surface.

NorlandOptical Adhesive81

Finally, for optical device reliability, adhesive compounds may be specially formulated to withstand environments of aggressive 85 degree C heat with 85 percent relative humidity, to ensure the adhesive remains physically and chemically sound.

Master Bond’s MasterSil 151 is a two-component, highly flexible silicone with superb optical clarity and a refractive index of around 1.405. It offers very low stress, and is suitable for use in various potting, sealing, and bonding applications involving substrates with different coefficients of thermal expansions.

Optical devices in the medical industry may require nontoxic transparent adhesives that bond tightly to a variety of surfaces while remaining immune to radiation, chemical, sterilization, and biological agents. Medical device manufacturers may impose additional requirements such as the ISO 10993-5 standard for cytotoxicity and/or USP Class VI specifications. Medical applications also present unique requirements for safe and reliable curing methods.

NorlandOptical Adhesive61

Another product, EP30-2, is a two-part, clear, low-outgassing epoxy which was qualified for use in critical bonding applications for the Laser Interferometer Gravitational-Wave Observatory, a.k.a. LIGO. The main applications involved bonding prism elements, and bonding acoustical dampeners to optical components.

The top and bottom of the hive like structure are engineered to reflect the light that would otherwise be lost. These panes have a stepped edges on both sides of the material, instead of just the outer surface and employ total internal reflection, which occurs when light hits a surface at or above the critical angle. The angle of the reflector’s grooves is specifically designed with this critical angle in mind. The light rays from the source have a small incident angle so they are captured by the prism

Norlandadhesive

The central light source radiates light in every direction and is very close to the lens, especially compared to the kilometer length scale the transmitted beam travels. As a result, the lens needs to have a short focal length so the light will focus into a collimated beam. Choosing the right focal length is important to ensure the light reaches its maximum range.

*Note: Fresnel was not the first to try to split traditional lenses to reduce their weight, but he came up with a practical and affordable design for use in Lighthouses.

While Fresnel lenses work very well for collimating a bright central light source, they can also be used to focus incoming collimated light. However, the placement of the lens needs to be precise to minimize the amount of aberrations that occur. The two most notable aberrations are spherical and chromatic. In both cases, the aberrations can be fixed with a multi-lens system, where light passes through more than one lens, whose curvature, focal lengths, and material properties can be specifically chosen.

EP42HT-2LTE is a two-component epoxy for bonding, sealing, coating, and select casting applications featuring an ultralow coefficient of thermal expansion. Photo credit: Master Bond

Using Snell’s Law, you can calculate how much a light ray will bend based on the refractive index of the materials, and the incident angle. If the surface is curved, like in a lens, then the amount of refraction of the incident light will depend on the distance of the incidence point from the optical axis. Parallel light rays incident on a convex surface will bend towards the optical axis, and converge at a focal point.

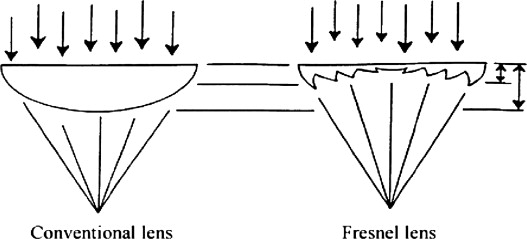

When visiting lighthouses built in the 19th century, you may notice a strange hive like glass cage around the lamp. These are the Fresnel lenses, originally designed by Augustin Fresnel*. At the time, lighthouses were starting to use lenses to extend the distance of the light beam. However, they faced a problem with traditional lenses, which were heavy and lost a lot of light. Fresnel realized that a lot of bulk glass could be removed and designed the strange lens with concentric stepped rings and a flat back. This new design collimates the light and reduces the loss. Today, they have many applications from bike lights to magnifying text. In this article we will learn how they work and how they can be used.

The specifics of any optical adhesive application must be examined, including the geometry of the parts and their dimensions. For example, in a fiber in a ferrule-type application, the compound should be very thin or have an ultralow viscosity, so that it can wick into very narrow gaps.

Polymer systems are engineered such that they can address these concerns across a wide range of CTE requirements. The use of additives such as aluminum oxide or negative CTE fillers such as zirconium tungstate can help achieve low to ultra-low CTEs. On the other hand, engineers can choose an optically clear silicone for applications requiring a flexible compound. Some silicone compounds offer excellent stress relief with their very low modulus of elasticity and low shore hardness levels after cure.

NorlandOptical Adhesive68

A traditional converging lens consists of at least one convex face. This face usually has spherical curvature, though other shapes are also used. For instance a parabolic lens will have fewer aberrations, but will be much more expensive. Other lens shapes include conical and cylindrical. Further, the way the lens is arranged will impact the way a lens focuses. For instance, having two convex surfaces will create a diverging lens in which the focal point lies behind the lens. On the other hand, prescription glasses usually have a meniscus shaped lens, where one side is convex and the other is concave. In all cases, the curvature of each surface can differ. These parameters all affect the focal length and magnification of the lens.

UV or dual-curing chemistries offer ultrafast fixturing and the ability to offer fast alignments in certain bonding situations. UV-curing adhesive systems cure with simple exposure of light of the required wavelength. In fact, dual-cure compounds cure on exposure to UV and to heat, simplifying manufacture of assemblies where UV illumination would be unable to reach concealed areas within complex geometries.

After polymerization, salient features for epoxies include dimensional stability, high modulus, low shrinkage upon cure, and a low coefficient of thermal expansion. The stress-reduction properties of adhesives are vital in many applications. Stress can arise at the bonded interface due to differences in the coefficient of thermal expansion (CTE) of the components. Over time, temperature variations can induce stress, separation, and eventual failure of the bond if large differences in CTE exist between the bonding material, and the components.

Some applications may require a transparent product with high light transmission, whereas other optical assemblies require an opaque compound with light-blocking properties. In many optical devices, the adhesive may not even be in the optical path.

Spherical aberrations occur when the light rays at the edge of the lens are focused at a different location than the rays near the center. This is caused by the shape of the lens, which most often has a spherical curvature. Changing the lens shape to have a parabolic curvature can correct the aberration, but will cost much more. A more cost effective route is to increase the radius of curvature of the lens, so the rays at the edge and the center are focused to the same point. However this increases the focal length of the lens.

An example of a first order Fresnel lens used by lighthouses, which is on display at the San Francisco Maritime Museum. Courtesy of National Park Service

UVadhesivefor glass

Optical AdhesiveFilm

Master Bond’s UV22DC80-1MED is a nano-silica filled, UV plus heat (dual) curable, USP Class VI and ISO10993-5 certified biocompatible and noncytotoxic adhesive that features excellent optical clarity and dimensional stability. It cures upon exposure to a UV light source emitting at 320–365 nm wavelengths with an energy output as low as 20–40 mw/cm2 and shadowed-out areas can be post-cured at 80 degrees C for around one hour.

The key element for lenses is the refractive index of the material they are built out of. This is a property of the material that makes up a lens. For example, air has a refractive index of 1 (it’s actually slightly greater than 1 but is often rounded down for simplicity) and glass has a refractive index of 1.52. When a beam of light travelling in air is incident on a glass surface, it will refract.

When looking at a Fresnel lens from a lighthouse, you’ll notice two distinct parts. The first is the set of rectangular pieces that sit around the center of the lens. This is what a typical Fresnel lens looks like, and is the main part of a Fresnel lens. Unlike a traditional lens, the surface of a Fresnel lens is broken up into rings that are arranged like a sawtooth when viewed from the side. This can be seen in the image above.

For instance, adhesive systems can vary from transparent to opaque. For optical devices, the tendency is to think that you always need optical clarity, but this isn’t necessarily so. There is no hard and fast rule for many optical applications, and the requirements can vary from case to case.

Chromatic aberrations, on the other hand, result from different wavelengths of light being refracted at different angles. The extent of this is determined by the lens properties. This is especially important to consider when using a polychromatic light source, like an incandescent bulb. In this case, the light source consists of the entire visible light spectrum, and the red wavelengths will refract at different angles than the blue wavelengths. Chromatic aberrations are harder to correct since they stem from the natural property of the lens material. However, most applications for Fresnel lenses do not require this step so chromatic aberrations are expected and tolerated.

Optical grade epoxies, silicones, and UV curable compounds provide solutions to engineers for bonding, sealing, coating, and encapsulating in fiber optic and optoelectronic applications, as well as in other demanding areas such as medical, military, and aerospace systems. But, as always, it’s important to pick the right “tool” for the job.

Master Bond’s EP42HT-2LTE is a two-part opaque epoxy, which offers the lowest coefficient of thermal expansion of 9 to 12 ppm. It meets NASA low outgassing standards and withstands 1,000 hours at 85 degrees C and 85 percent relative humidity. It is a great fit for optical bonding and mounting applications where high levels of dimensional stability are needed.

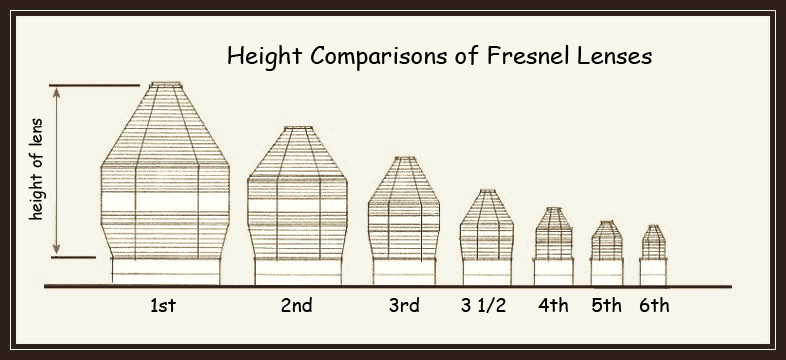

As a result, Fresnel created a 6 order system, detailing the size of each component, the focal lengths, where to use each order, and even the number of wicks for the central light source. This list was expanded later to include a few larger and smaller lenses. The first order, and originally the largest, Fresnel lens has a focal length of 92 cm and an approximate visibility of 35 km. On the other end, the sixth order Fresnel lens has a focal length of 15 cm and a visibility of 8 km.

Ms.Cici

Ms.Cici

8618319014500

8618319014500