How to Select the Right Memory Card for Your Use - factor 75 cam

Rollers are one of the most affordable solutions for moving your stages. However, they’re also one of the most basic; they allow for less accuracy than the other options.

When working on the nanoscale, it’s all about the detail. Factors such as flatness, perpendicularity, and straightness all take high priority. A high-precision XY stage is critical.

Infraredpronunciation

However, the effects of these disadvantages are so microscopic that they’re still suitable for many applications. And there are ways to combat these problems.

A high-performance XY stage excels in each area the client needs. But that depends on the intended use of the stage. Here are some examples of XY stage applications and which high-performance elements are most necessary.

Therefore, a motorized and automated stage is used to move the slide around. It adjusts remotely and robotically according to the instructions it’s given. They need to be able to move across both the X and Y axis so that on a 2D plane, the user can move their slide up, down, left, and right.

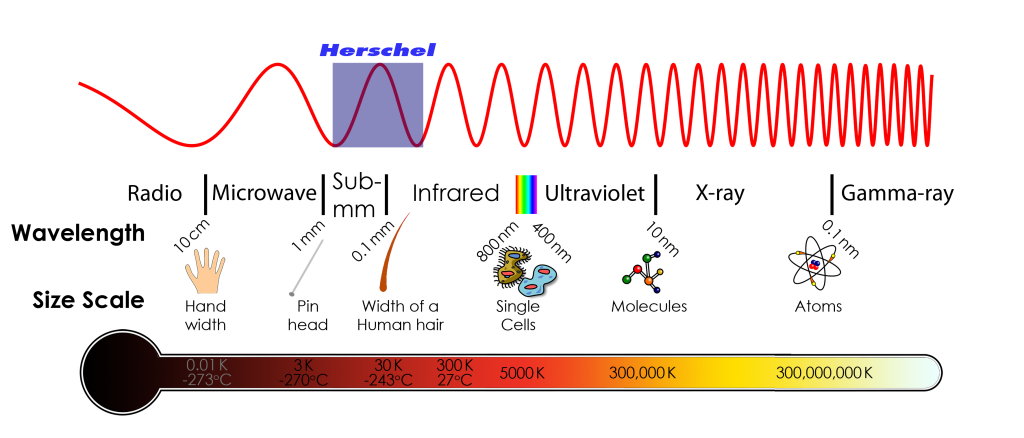

In fact all objects glow (emit electromagnetic radiation), and they do this in the part of the electromagnetic spectrum that depends on their temperature. The diagram below shows how bright objects of different temperatures appear at difference wavelengths.

Load capacity is the weight that the machine can support. This is usually unimportant when dealing with positioning systems on a microscopic scale.

A stepper motor moves your linear stages in set stepped increments. It is the most basic and affordable of the two motors, but it is still highly effective. It requires fewer components to work and is better for slower-speed usage.

As with any product, higher-performing versions will last longer. They take less wear and can bear more use without needing maintenance, repairs, or replacement.

At the same time, the stages need to keep up with the pace required in manufacturing. So high speeds, minimal settling times, and repeatability need to be just as high performing.

Now you have a comprehensive understanding of XY positioning systems, the question is, “What makes an XY stage high-performance?”

If you haven’t been able to find the exact solution you need, ordering a custom stage will yield the best results. It ensures you can prioritize the factors you need to be high performing without buying the most expensive machine out there.

Air bearings are the advanced cousin of a ball bearing. They allow for some of the flattest movement possible in an XY stage.

It is interesting that the basic technique used by Herschel to discover infrared radiation is still used in modern instruments today, including instruments on board the Herschel satellite – the only real difference is a factor a billion or so in sensitivity.

We humans, slightly warmer than room temperature, glow in the mid infrared and we’re brightest at about 10 microns wavelength (black line in the graph). These days we are all familiar with infrared imaging, which allows us to see in the dark using electronic detectors that record infrared light emitted by warm objects such as people. The pictures below show SPIRE team member Prof. Peter Ade in visible light (wavelength about 0.5 micron) and infrared light (about 10 microns).

XY stages are not limited to microscope usage. They’re an essential feature of linear motion engineering. They are a type of linear translation stage.

As semiconductors get smaller and smaller, the engineered systems used to make them need to become more accurate. Precision factors, such as flatness, straightness, and perpendicularity, are crucial.

However, performance levels in load bearing are inconsequential. Speed may also not be a priority, depending on the specific application.

Clearly, depending on what it is that we want to observe, we need to look in different parts of the spectrum, and no one part will tell us everything. The Earth’s atmosphere transmits well in the visible and radio regions, but it blocks out everything from gamma rays to ultraviolet and most of the infrared. So to study the Universe at those wavelengths we need to launch space-borne observatories.

Open frame XY stages are a type of integrated stage designed to allow for non-epifluorescence imaging. In other words, it has clear elements that will enable the slide to be illuminated from underneath.

The Sun has a surface temperature of nearly 6000 Kelvin (where the Kelvin temperature scale is the same as the familiar Centigrade scale except that the zero degrees C is about 273 degrees Kelvin). Its radiation peaks in the visible part of the spectrum at wavelengths of about half a micron, as shown by the yellow-green line in the graph above.

High bi-directional repeatability levels are particularly impressive, as they show that the stage accounts for backlash and other changes while remaining precise and accurate.

XY stages have been used by scientists for decades to make microscopes more effective. They are now more advanced than ever before, capable of nanometer movements.

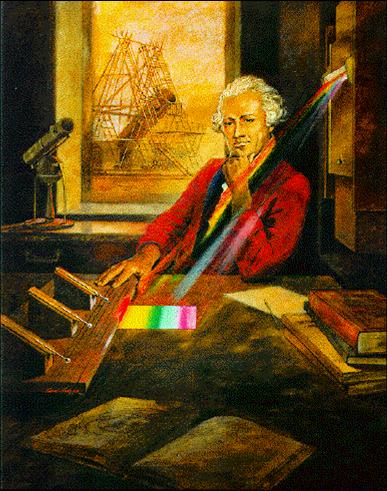

Infrared radiation was discovered by William Herschel in 1800. He was studying the heating effect of different colours of light by using a prism to produce a spectrum of colours and thermometers to measure their heating effect. He noticed that the heating effect got stronger as he went from the blue end of the spectrum to the red. In a moment of inspiration, he moved the thermometer beyond the visible red end and found that the heating effect was even greater.

Crossed rollers are an upgraded version of the roller mechanism. They remain affordable but allow for more stability and reliability, increasing the application of rollers.

Whether you’re looking for an X, XY, or XYZ stage, Motion Solutions is leading the market with its advanced offerings. Not only that, but we can custom-build XY stages specific to your needs.

As technology progresses, manufacturers introduce new features to keep their stages at the forefront of the market. They’re far more intricate and powerful now than they were even five years ago.

Planar stages are the most precise piece of axis linear equipment available today. Instead of using mechanical bearings on cross rollers, they run on air bearings. The best of these positioning stages achieves a flatness of 1µm or less.

The whole region with wavelengths ranging from 1 micron to 1 mm is loosely called the “infrared”, but astronomers tend to break this up into sub-regions: the “near infrared” (from 1 to 5 microns); the “mid infrared” (5 to 30 microns), the “far infrared” (from 30 to 300 microns) and the “submillimetre” (from 300 microns to 1 mm). The exact boundaries are somewhat arbitrary, and the exact definitions can vary.

XY stages serve a variety of roles in the medical industry. One example is medical equipment positioning. Surgical equipment can be precisely positioned for use using overhead gantries.

Infraredwavelength

Flatness is vital so that the XY stage remains on the XY plane. But added to that is the need for the stages to move in an ideal straight line on both the X and Y axis. The highest-performing stages achieve near-perfect straightness levels.

For them to work to their full potential, they must be supported by the highest-grade equipment, such as a granite base. Therefore, they’re generally one of the most expensive options.

Infraredexamples

To decide whether you need low or high-wear elements, consider how much use your stages will get regularly. Also, be sure not to push your machine past its load capacity and other limits. That will help it to last as long as possible.

Automated and even semi-automated stages make automation more efficient. In this application, speed, settling time, and repeatability are often crucial. They enable automation to run endlessly unattended because the stages can be relied upon to stay accurate.

The advantages of a stacked stage include the flexibility of stacking two different models, each of which will offer its own strengths. The simplicity of the design also makes it one of the most affordable XY stage options.

There are many factors that mean a linear stage is high-performance. Often, the one users are most concerned with is flatness. An XY stage should stay as flat as possible, whether the application is microscopic or not.

X stages also exist, which move on a single axis. And as the name suggests, XYZ stages can move in ideal straight lines in three directions.

Stacked stages got their name because they’re made of two X stages stacked on top of each other. These two single-axis stages are stacked at opposing angles so that one serves as the Y-axis.

But as you will see, XY stages have many starkly different applications. Some models can support a high load, even up to 650 lbs, such as for use in aerospace engineering.

Infraredwaves

A low settling time is essential if you need a product that moves at high speeds with no pauses between movements. But this isn’t necessary for all applications. You can still choose a high-performance XY stage with incredible flatness but a longer settling time.

Clouds of interstellar gas and dust that form stars are typically at temperatures of about 50 K (that’s about –220oC). They glow at far infrared wavelengths and are brightest at about 100 microns (red line in the graph above). And the universe itself is filled with radiation corresponding to a temperature of just less than 3 K – very cold indeed – with peak emission in the millimetre wavelength range (blue line in the graph above).

Calibration can become an issue because two separate machines are involved. As the two stages are stacked, the top stage has less support, as it’s not sitting on a solid surface. Improperly cantilevering them can present further rolling and calibration issues.

Each combination of motor and mechanism has a different settling time. That is, how long it needs to pause in position and settle before it moves again.

Infrareduses

How do XY stages achieve the movements needed for microscopy applications at such high speed? The answer is a combination of movement mechanisms and motors that differ from machine to machine.

In these cases, load capacity is crucial to take the weight of the equipment. At the same time, precision is necessary for areas such as straightness and perpendicularity. But factors like settling time may be less critical.

One solution is using a gantry system. This specially designed stacked XY stage ensures each stage receives the support it needs. Rather than making an XY stage yourself, you’ve invested in a ready-made stacked system that is balanced and calibrated.

The only notable limitation of any integrated stage is that it operates on mechanical bearings, as do stacked stages. These bearings are incredibly effective at leveling out microscopic changes on the surface so that the stage moves as linearly as possible. But mechanical bearings can only do so much.

Infraredlight

A repeatability measure shows how accurately your machine will return to the same spot when the instructions are repeated. It must be fast and stop exactly where it’s told.

The electromagnetic spectrum spans a wide range of wavelengths from very short wavelength and highly energetic gamma rays to very long wavelength and low-energy radio waves. The visible part of the spectrum is only a small portion. Infrared light is the same as the light that we can see except that the wavelength is longer and outside the range that our eyes can sense.

To help you keep up to date with the latest developments in XY stage technology, we’ve created this brief guide to high-performance XY stages. We’ll explain how they work, their wide range of applications, and how to choose the right stage for your needs. Read on for all you need to know about XY stages.

The movement mechanisms allow the linear stages to move along the X and Y plane as flatly as possible. Stages commonly use one of the following four options to do this.

Also called monolithic stages, integrated stages operate the X and Y axis on one level rather than stacked on top of each other. This means they have a much lower profile and potentially are better suited to microscopy applications.

XY stages that are flexure-guided, also known as piezo flexure stages, are known for their low wear. In theory, flexure systems won’t wear out but can be used infinitely. Of course, that also makes them one of the most expensive systems.

Infraredfrequency

The more microscope technology and its applications grow, the more powerful microscope stages need to become. Stages have advanced in leaps and bounds from their first introduction, embracing motorization and automation technology. The most common of these are XY stages.

Novanta Inc. (Nasdaq: NOVT) (“Novanta” or the “Company”), a trusted technology partner to medical and advanced technology equipment manufacturers, announced today that it has finalized a definitive agreement to acquire Motion Solutions, a leading provider of highly engineered integrated solutions.

The speed at which linear stages move is inconsequential in some industries but crucial in others. High-speed stages require more expensive components to operate effectively but are a necessary investment for some applications.

Flatness is paramount because it significantly reduces optical focusing times if the stages always stay at the same height.

Infrareddefinition

Like rollers, ball bearings are a cost-effective solution. They are also more versatile in the type of stage they work in, making them a popular choice.

Servo motors are more complex and require an encoder to work. But that makes them more accurate. They are also the more efficient of the two and are better suited to high-speed applications.

Within the umbrella of XY translation stages exist several specific types of linear motors. These include integrated, stacked, and planar XY stages.

A linear translation stage moves by motorization in an ideal straight line. XY stages are motorized stages that can do this in two directions: the X and Y axis.

Straightness measures whether lines ever deviate from their X or Y axis. But perpendicularity expresses whether the two planes stay at a 90-degree angle from each other. The lower the perpendicularity score, the higher performing the machine.

When a microscope user needs to move their slide, they can do so by hand. Outside of a high school science lab, that’s generally too primitive for scientific application. Powerful microscopes reach such high magnification levels that moving the specimen around requires more precision than the human hand can offer.

Microscope application continues to widen from biological studies to non-organic matter, blurring the lines between the tech and medical industries. This significantly contributes to exponential microscope demand.

Ms.Cici

Ms.Cici

8618319014500

8618319014500