Gaussian beam - gaussian beam calculator

Anti reflectionglasses

ECI’s AR Coatings meet the reflection and environmental requirements of MIL-C-14806A and MIL-C-48497. Designs comply with military and telecommunication industry standards.

Maintain beam collimation between a CO₂ laser and the final focusing optics in a system with our long focal-length lenses and mirrors.

Highest quality firewire cables allow for transfer rates up to 400 Mbps and meet the IEEE-1394 specification. These cables allow for simple.

Antireflective glasses vs blue light

ECI has extensive experience coating polymers and other temperature sensitive substrates. ECI has been coating polymer optics for over 60 years. Our low temperature Anti-Reflection coatings are designed and deposited to ensure good adhesion and thermal stability on even the most challenging polymer substrates. ECI coats different types of substrate with low temperature Anti-Reflection coatings at process temperatures below 50°C. These substrates range from plastic windows and lenses to optical fibers and fiber optic assemblies/components including: Molded Polymer Optics, Polycarbonate, Acrylic, Zeonex®, Ultem®, Mylar®, CR39, COC, Fresnel Lenses, TO-Window Cans, MT Ferrules.

Magnifying Lamps Guide. Omano Magnifier Lamp. A magnifying lamp is an essential tool for anyone working with precision assembly, inspection or design.

© Copyright 2011 - 2022 Evaporated Coatings, Inc. All rights reserved. Careers Privacy Policy Terms of Service Sitemap

Anti reflectioncoating

Silicone immersion oil is used for deep observations of live specimens. Silicone oil (ne≒1.40) closely matches the refractive index of cells (ne≒1.38) thereby ...

antireflective coating中文

Description: Cylindrical lenses focus or expand light within a single axis only. N-BK7 cylindrical lenses are manufactured from fine annealed glass and polished ...

ECI deposits High Power Anti-Reflection coatings on several different types of substrates, including but not limited to Glass/Fused Silica windows, lenses and wafers, Fiber optic cables and assemblies, LBO, BBO, KTP, TGG, GGG, BiG, and Silicon wafers.

anti-glare什么意思

ECI’s durable films on plastic and polymer molded optics are resistant to organic solvents and are an excellent choice for a wide variety of products.

Oxford University Press is a department of the University of Oxford. It furthers the University's objective of excellence in research, scholarship, and education by publishing worldwide

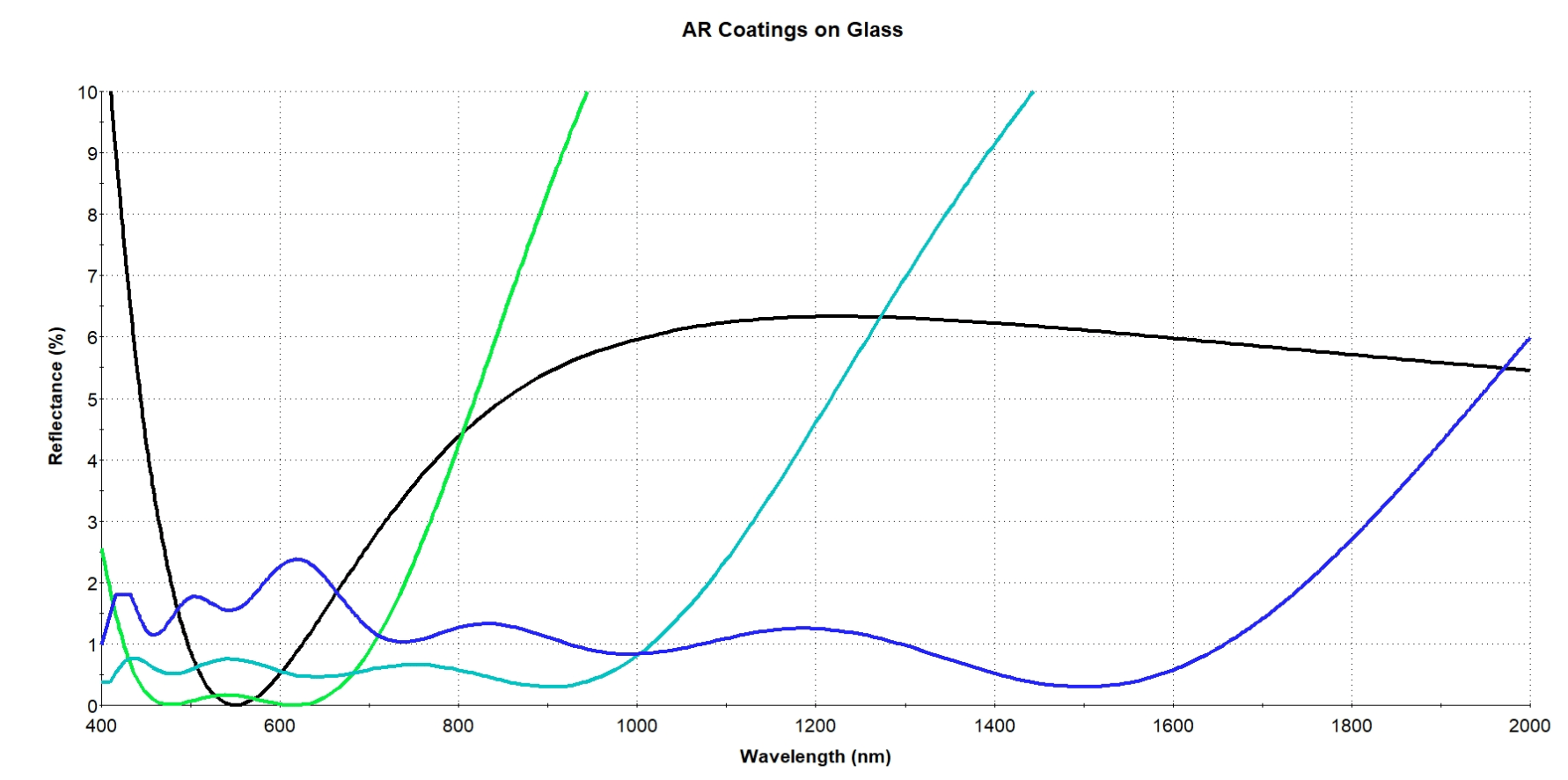

ECI also deposits high temperature Anti-Reflection coatings on various substrates, including crown glasses, float glasses, Fused Silica, Sapphire, Silicon, CaF2, and others. ECI can deposit these coatings to cover any wavelength range between 200 – 2500nm. These coatings are designed and deposited to meet the durability requirements per MIL-C-675C. ECI deposits Anti-Reflection coatings on parts up to 400mm in diameter.

14 (not available). Ship it to me. Free shipping ... Buy Gola International 4 Inches Diameter ... Store Locator · Accessibility Statement · Privacy Policy ...

Sensors Unlimited, Inc. produces NIR and SWIR cameras and arrays - all based on InGaAs imaging technology - that see beyond the visible wavelength spectrum.

Anti-reflection coatings reduce first surface reflection losses, improve contrast and boost the transmission through your optical surface. Choose from a typical design below or ECI will design and deposit a custom anti-reflection (AR) coating for your specific application. If you are not sure how to specify your coating, our design team will work with you to identify the optimum design for your system.

Antireflective coating spray

anti-reflective coating是什么

Luvvitt Liquid Glass Lens Protector For Eye & Sunglasses & Camera Lenses · Effector Liquid Unisex Glasses-Sunglasses · Anti Motion Sickness Glasses Liquid Glasses ...

Antireflective glasses Specsavers

Typical values verified through independent test laboratories. Actual LDT performance is dependent on substrate selection, surface preparation, and system design.

F. Zernike, F.J.M. Stratton, Diffraction Theory of the Knife-Edge Test and its Improved Form, The Phase-Contrast Method, Monthly Notices of the Royal Astronomical Society, Volume 94, Issue 5, March 1934, Pages 377–384, https://doi.org/10.1093/mnras/94.5.377

The axicon is an optical element which creates a narrow focal line along the optical axis, unlike the single focal point produced by a lens.

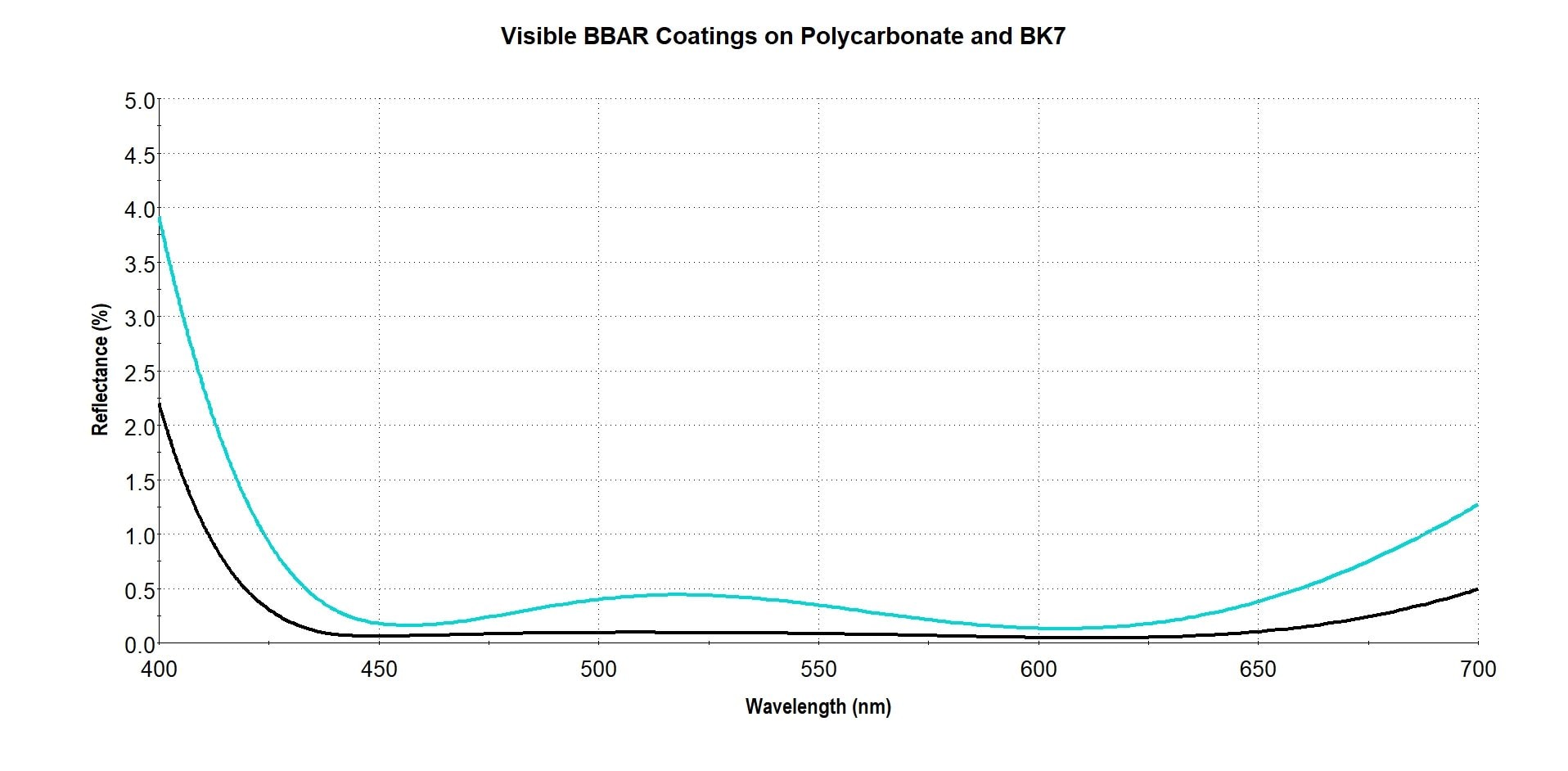

Evaporated Coatings Inc. offers anti-reflection coatings for a variety of substrate materials and configurations. Different coatings materials are selected depending on the substrate material, size, shape, and wavelength range of interest. In many cases, the choice of substrate material dictates the deposition temperature of the AR coating. For narrowband Anti-Reflection coatings, the optical performance is similar for both low and high temperature depositions. However, the performance of a broadband AR Coating will vary depending on the deposition temperature. Typically, broadband AR coatings deposited at higher temperatures will yield lower average reflection over a particular bandwidth. There are two primary reasons: 1). certain coating materials require deposition at elevated temperatures for sufficient durability and 2). the refractive indices of some materials decrease when deposited at lower temperatures. For example, a visible broadband AR coating on BK7 will have slightly better optical performance than a visible broadband AR coating deposited on Polycarbonate. Figure 2 shows the difference in performance between the two substrates mentioned above.

Anti-Reflection Coatings can be optimized for narrow and broadband applications. The performance of an AR coating will vary depending on the bandwidth and angle of incidence (AOI). ECI can typically achieve front surface reflection less than 0.03% for a narrowband AR coating at near normal incidence. Anti-Reflection coatings optimized for wider bandwidths will display a higher maximum reflection. A typical Broadband Anti-Reflection coating on glass will have a maximum reflection of less than 0.5% with a typical average reflection of 0.25%. Figure 1 shows how reflection performance can vary with bandwidth.

AR Coatings ( Anti-Reflection coatings ) are deposited onto optical surfaces to reduce specular reflectivity. Anti-Reflection coatings are comprised of a single layer or multiple layers. These designs are optimized to create destructive interference with respect to the reflected light. This design approach will allow the maximum amount of light transmission without compromising image quality. Diagram 1 is an example of a typical multilayer Anti-Reflection coating.

Anti-Reflection coatings are utilized in a variety of applications. It is very common for AR coatings to be used in laser applications. In such cases, Anti-Reflective coatings will need to meet or exceed certain LDT ( Laser Damage Threshold ) requirements. ECI primarily uses Ion Beam Sputtering ( IBS ) or Electron Beam ( E-Beam ) to deposit AR coatings that must withstand high power lasers.

The Nikon FITC-TRITC filter set is designed for optimal detection of FITC ... FITC-TRITC filter ... The shorter wavelength signal channel of the ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500