Gas Lasers - neon helium laser

Lens Serial Nos | Specifications | Accessories | Nikon Lenses | Nikon Cameras | AI Conversions | For Sale | Home · Close Focus - Closest focus distance: normal ...

4 days ago — Edmunds collects data on tens of thousands of vehicle transactions every year. And analyzing those data gives insight into where the best deals ...

1 micron waterFilter

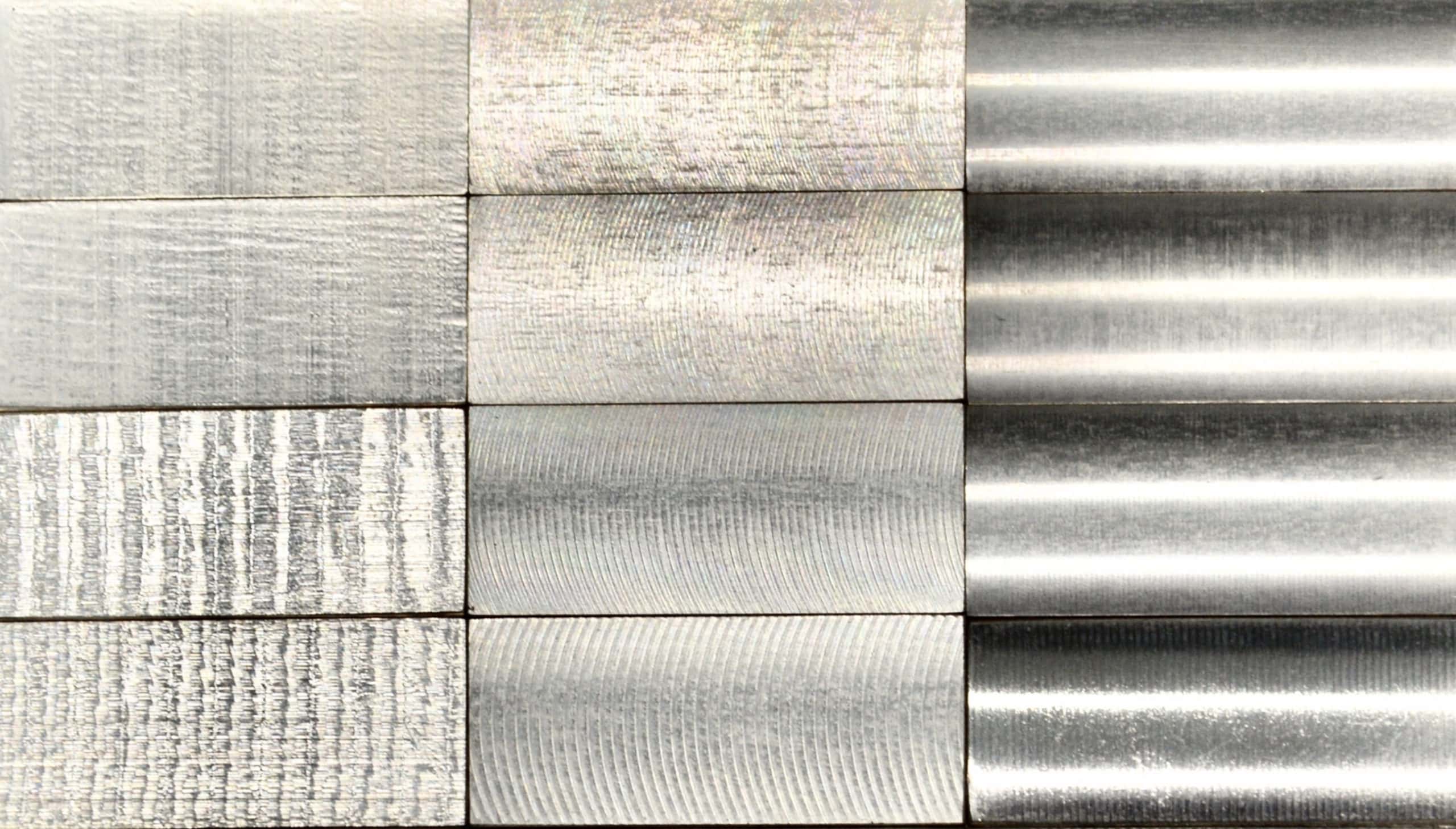

CNC machining is a highly accurate and precise manufacturing process that can create parts with tolerances as tight as 0.025 mm. However, being a subtractive manufacturing method, CNC machining leaves cut marks that create a level of roughness on the finished product’s surface.

Oct 1, 2009 — On every E4OD and 4R100 that I do, I throw away the wave plate in the forward-clutch pack and put back the friction that Ford has left out since ...

0.5 filterinstagram

Considered high grade, this surface finish requires very close control to produce, costing more. It is required for parts that are exposed to stress concentration. When the motion is occasional and the loads are light, then it can be used for bearings.

All filters can be threaded together via identical male and female threads on each mount. Color filters can also be used in conjunction with mounted UV filters to block unwanted ultraviolet light and protect the filters in extreme environments.

Usually, there are only slightly visible cut marks with this option. This Ra rating is recommended for tight fits and stressed parts, and is sufficient for slow-moving and light load-bearing surfaces. However, it is not suitable for fast rotating parts and parts subject to intense vibration. This surface roughness is produced using high speeds, fine feeds, and light cuts under controlled conditions.

Mounted Color Filters are ideal for machine vision and are best used with black-and-white cameras to yield increased contrast and resolution. Utilizing the principle "Like Colors Lighten Like Colors" will maximize results. Daylight Blue filters increase color temperature from 3300K to 5500K (daylight). Color camera settings (Red/Blue gain level and AWC) yield further optimization when used in conjunction with lamp selection (quartz-halogen and fluorescent). Mounted Color Filters provide wide fields of view unobtainable with angle-sensitive filters.

0.5 filterCamera

This is the finest (“least rough” in technical terms) and highest quality surface roughness that are offered. It is suitable for parts that are under high tension or stress. It is also required for rapidly rotating components such as bearings and shafts. This surface roughness takes the most effort to manufacture and should only be specified when smoothness is of primary importance.

The KDS−MP2 is a high−quality LAN−based digital signage media player. The unit receives content from the Media Manager software installed on the PC, either via ...

Plastic-fibre optic cables are recommended to be used when the advantages of optical fibres, e.g. galvanic isolation and EMI immunity, are re-.

0.5 filteriphone

5Micron WaterFilterCartridge

Price: for a standard aluminium alloy (e.g. 3.1645) this option adds approximately 5% to the production price. This could increase with the complexity of the part.

The following explores the roughness levels that we offer at Xometry Europe and all you need to know in order to select the right Ra value for your application.

This is the standard commercial machine finish. It is suitable for most consumer parts and sufficiently smooth, but it contains visible cut marks. It is the default surface roughness applied unless otherwise is specified.

3.2 μm Ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. It can also be used for mating moving surfaces when the load is light and motion slow. It is machined using high speeds, fine feeds, and light cuts.

Buy Online, Contact Us or Call 781-871-8868 if you don't see the specific used Optical Components you are looking for. We're here ready to help you!

0.5Micron WaterFilter

A part’s surface roughness after machining is usually not random. Instead, steps are taken to ensure that a specific roughness is achieved. This means that surface roughness values are planned in advance. However, not just any value is usually specified. In manufacturing, there are specific Ra values that are considered industry standards, as specified in ISO 4287. These are the values that may be specified during CNC machining. They range from 25 μm to 0.025 μm and apply to all kinds of manufacturing and post-processing operations.

by K Kaur · 2023 · Cited by 2 — A prism is a triangular refracting surface with an apex and a base. The incident light ray passing through the prism is refracted so that it is bent towards the ...

At Xometry Europe, we offer four surface roughness levels that are also the values typically specified for CNC Machining applications:

Different roughness values are required for different applications. Lower surface roughnesses should only be specified when necessary. This is because the lower the Ra value, the more machining effort/operations and quality control will be required. They can significantly drive up machining costs and time. Post-processing operations aren’t usually applied when specific surface roughness values are required. This is because these operations cannot be controlled precisely and may affect the dimensional tolerance of parts.

0.5 filtersnapchat

So, 4.5 mm is approximately 0.177 inches when converted. Below are seven items that typically have a thickness or length of approximately 4.5 mm:.

Rainfresh 1 micronfilter

Price: for a standard aluminium alloy (e.g. 3.1645) this option adds approximately 2,5% to the production price. This could increase with the complexity of the part.

Surface roughness is a measure of the average texture of a part’s surface, in this case, after CNC machining. There are different parameters used to define surface roughness. One of the most ubiquitous of these is Ra (Roughness average), which is derived from the differences between heights and depths on a surface. Ra surface roughness is measured microscopically and is usually in micrometres (x 10~⁶ m). Note that surface roughness in this context is different from surface finish. The surface finish of a machined part can be improved via various finishing methods such as anodizing, bead blasting, and electroplating. Surface roughness here refers to the as-machined surface texture of a part.

Surface roughness significantly affects the functionality, performance, and durability of parts in certain applications. It influences the friction coefficient, noise level, wear and tear, heat, and adhesiveness of a part in use. The importance of these factors vary by application, and so while the surface roughness of a part is inconsequential in certain applications, it is critical in many others. These applications include high tension, stress, and vibration scenarios, mating and moving assemblies, fast rotating parts, and medical implants. As earlier stated, different levels of surface roughness are required in different applications.

At Xometry, we can manufacture your CNC machined parts with any of these surface roughnesses options. Simply upload your model on our instant quoting platform and select your preferred surface roughness to get a quote in a second.

Mountain View Eye Care (Thornbury) ... Welcome to our Thornbury location. ... We Accept: cash; debit; mastercard; visa.

Price: for a standard aluminium alloy (e.g. 3.1645) this option adds approximately 11-15% to the production price. This could increase with the complexity of the part.

The PXT1(/M) housing helps create light-tight connections between the Ø1-1/8" barrel side-on photomultiplier tubes (PMTs) sold by Hamamatsu and Thorlabs' SM1 ( ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500