Fresnel Lenses, Handheld Magnification - fresnel lens for reading

Change Filters Regularly: Filters prevent contaminants from damaging your system, but they can get clogged over time. Replace filters as recommended to maintain optimal air quality and system performance.

Compressed air is all around us, but where is it used exactly? Discover the different ways compressed air is used and how it impacts our everyday lives.

Air Dryer: Moisture is a common issue in compressed air systems. An air dryer is used to remove excess moisture from the compressed air, protecting downstream equipment and preventing corrosion. Popular types include refrigerated and desiccant dryers.

Air Compressor: The core of the system, the air compressor takes in ambient air and compresses it to a higher pressure. Whether you're using rotary screw, reciprocating, or centrifugal compressors, the role remains the same—producing compressed air for your application.

Together with electricity, water and gas, compressed air keeps our world running. We may not always see it, but compressed air is all around us. Because there are so many different uses for (and demands of) compressed air, compressors now come in all kinds of different types and sizes. In this guide we outline what compressors do, why you need them and what types of options are available to you.

Simple microscope and compound microscopeClass 12

Discover the history of simple and compound microscopes in this first of our two-part series on the history of microscopes.

Join UsSign up for our feature-packed newsletter today to ensure you get the latest expert help and advice to level up your lab work.

Difference between simple and compound microscopepdf

Another advantage of compressed air is its flexibility. It is ideal for use in remote areas such as mines or construction sites, where electrical power may not be readily available. Air compression tools, such as rock drills, run cooler and provide variable speed and torque, making them more suitable for heavy-duty applications in these environments. Achieving similar force with electricity would be difficult, especially in remote areas.

Filters: Compressed air filters are crucial for removing contaminants like oil, dust, and water from the system. Keeping your air clean ensures the longevity of your tools and the reliability of your system.

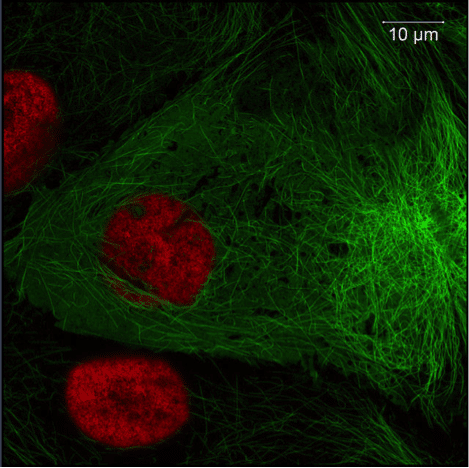

Using fluorescent proteins as imaging probes is a widespread and versatile technique in microscopy. You can use them in a wide range of living systems, from single cultured cells to complete organisms and animals. Fluorescently tagged proteins can be used to track and examine real-time localization, interactions and translocation of your protein of interest, as…

Compressed air-powered tools are also lighter. They can be made from materials that reduce weight, making them more ergonomic and reducing worker fatigue. This balance between the cost of compressed air and labor costs helps improve efficiency on job sites where tools are used for extended periods.

Air Receiver Tank: This tank stores compressed air and helps balance supply with demand, ensuring a steady flow of air while reducing pressure fluctuations within the system.

The primary component of compressed air is, of course, air itself. But what is air? Air is a gas mixture, consisting mainly of nitrogen (78%) and oxygen (21%). These gases move around, and their movement creates kinetic energy.

Difference between simple and compound microscopeClass 12

Would you eat your spaghetti dinner without a plate? No, of course not! It would make a big mess and be ugly to look at. Instead you NEED something to put that spaghetti on, to contain it, to keep it clean, to make it look nice – a bowl, a plate, SOMETHING! By the same…

So, how does air compression work? When you compress air, you force its molecules into a smaller space. This increased density makes the molecules move faster, increasing their kinetic energy and, therefore, the temperature. This is known as the "heat of compression." Essentially, you're storing energy in compressed air for future use by squeezing it into a smaller volume.

Inspect the Compressor: The air compressor is the heart of the system, so it's important to regularly inspect and service it. Keep an eye on oil levels (if applicable), check for unusual noises, and ensure it’s operating within the recommended parameters.

One of the key reasons for using compressed air instead of electricity is safety. In certain applications, especially when equipment is overloaded, electrical equipment may pose a safety risk, including electrical shocks or fire hazards. On the other hand, compressed air and pneumatic tools can be safely used in environments with wet floors or high humidity, where electricity may not be practical.

When it comes to cost, while the energy cost of compressed air can be higher—up to 7 or 8 times that of electricity—the equipment designed for compressed air use tends to be less expensive. Pneumatic tools typically have fewer parts and simpler designs, making them more durable and rugged, particularly in production environments.

You are using a browser we do not support any longer. To continue visiting our website, please choose one of the following supported browsers.

There are a lot of things you have to consider when choosing an air compressor for your business. In this article we will explain what compressor is best suited for you, based on your application and needs.

Simple microscope

To understand the workings of compressed air, a basic introduction to physics can come a long way. Here we give an introduction to maybe the most important element in compressed air: the air itself. Learn more.

Each of these compressed air system components, including chillers, plays a critical role in ensuring your system operates effectively, delivering the required air pressure and quality.

In the same way that you should ‘Think Before You Fix’, the choice of embedding media should be dictated by your required end-point. The basic principle is that by processing tissue into an embedding medium you harden the tissue and provide support protecting it from the mechanical forces associated with sectioning. Parma ham and steak…

Simple compound microscope

Take the example of a balloon: when you inflate a balloon, you're forcing air into a smaller volume. The energy stored in the compressed air within the balloon is equal to the energy you used to inflate it. When you release the balloon, the compressed air escapes and causes it to fly away. This is the same principle that positive displacement compressors use to compress air.

Did you know compressed air is considered the fourth utility? Alongside water, electricity, and gas, compressed air has become essential for both small businesses and large enterprises due to its widespread use.

A compressed air system consists of various essential components that ensure efficient, reliable operation. These components work together to produce, treat, and deliver compressed air to the point of use. Below are the key components:

Check for Leaks: Air leaks can be a major source of energy loss in your compressed air system. Regularly inspect fittings, pipes, and connections to identify and fix leaks, ensuring maximum efficiency.

List five differencesbetween a simple and compound microscope

Difference between simple and compound microscopeclass 9

Maintaining your compressed air system is essential for extending its lifespan and ensuring consistent performance. Here are a few simple tips to keep your air compression system running smoothly:

We will explain what compressed air is, why do we use it and how it is created. We’ll also cover some popular concepts of compressed air along with examples.

You’re a senior postgraduate student, a post doc or a junior PI with little knowledge on microscopes and someone between Senior PI /Dean level approaches you with this: “We have now the funds to buy the fluorescence microscope someone once told me we need. Can you handle this please? Oh, by the way, the funds…

Difference between simple and compound microscopein tabular form

Monitor the Air Dryer: Moisture can cause serious issues in your compressed air system, so regularly check and maintain your air dryer. Make sure it’s functioning properly to keep your system dry and free from corrosion.

Chillers: In some compressed air systems, heat generated from air compression needs to be managed. Industrial chillers are used to cool the compressed air, improving efficiency and preventing overheating of equipment. Chillers are essential in maintaining the optimal temperature of the system and ensuring consistent performance.

Compressed air is a fantastic medium for storing and transmitting energy. It’s versatile, flexible, and relatively safe when compared to other energy storage methods, like batteries or steam. Batteries are bulky, have limited charge cycles, and lose efficiency over time. Steam, while powerful, isn’t cost-effective or user-friendly (due to the extreme heat involved).

Martin gained a PhD in Nanotoxicology from Edinburgh Napier University, has around 20 years experience in biomedical research, extensive experience in light microscopy, and has established and managed a microscopy facility.

The temperature of the air is directly proportional to the mean kinetic energy of its molecules. In simple terms, when the molecules move faster, the air temperature rises. When they slow down, the temperature drops.

Whether you know it or not, compressed air plays a crucial role in our daily lives. From inflating balloons at birthday parties to powering industrial tools, compressed air is everywhere. It even helps manufacture the phone, tablet, or computer you are reading this on.

By following these simple tips, you can ensure that your compressed air system remains efficient, reliable, and cost-effective.

Are you an assiduous biologist who prefers label-free imaging methods for biological samples analysis? Raman spectroscopy offers you a wonderland of imaging technique with unlimited benefits. To start with, Raman Spectroscopy is a spectroscopic technique based on inelastic scattering of monochromatic light usually from a laser in the visible or near infra-red part of electromagnetic…

But how does compressed air compare to electricity? While electricity is generally more cost-efficient, compressed air has its own advantages, especially in industrial settings where safety, power, and versatility are critical.

Ms.Cici

Ms.Cici

8618319014500

8618319014500