Fresnel Lenses - fresnell lens

Pt The maximum total height of the profile (Rmax in the case of JIS’82) Wt The maximum total height of the waviness

Rmr indicates the material ratio determined by the difference Rδc between the referential section height level C0 and the profile section height level.

Note This parameter relates to the tip geometry of peaks and valleys and is suitable for analyzing the degree of contact between two objects.

Minimum height discrimination: 10% of the Rz value Minimum length discrimination: 1% of the reference length

Note This parameter relates to the tip geometry of peaks and valleys and is suited to analyzing the contact between two objects.

Pmr (c) The material length rate of the primary profile (formerly tp) Wmr (c) The material length rate of the waviness

This is the number of peaks per unit area. Only peaks that exceed a designated size are counted. Unless otherwise specified, the designated size is determined to be 5% of the maximum height Sz.

Surface roughnessRa chart

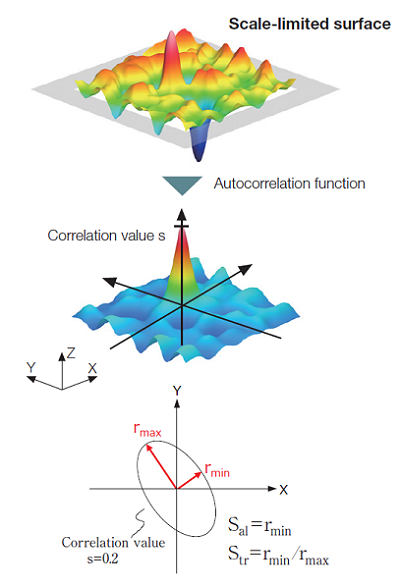

The Str value ranges from 0 to 1; normally Str > 0.5 indicates a strong isotropy while Str < 0.3 is strongly anisotropic.

Rk Core roughness depth Rpk Reduced peak height Rvk Reduced valley depth Mr1, Mr2 Material portion

Terms Of Use | Privacy Notice | Cookies | Cookie Settings | About Us | Imprint | Careers | Careers | Sitemap

This parameter expands the profile (line roughness) parameter Rdq three dimensionally. It indicates the mean magnitude of the local gradient (slope) of the surface. The surface is more steeply inclined as the value of the parameter Sdq becomes larger.

AR Mean spacing of roughness motifs: the arithmetic mean of roughness motifs ARi calculated from the evaluation length R Mean depth of roughness motifs: the arithmetic mean of the roughness motif depth Hj calculated from the evaluation length Rx Maximum depth of roughness motifs: the maximum value of the Hj calculated from the evaluation length AW Mean spacing of waviness motifs: the arithmetic mean of the waviness motif AWi calculated from the evaluation length W Mean depth of waviness motifs: the arithmetic mean of the waviness motif depth HWj calculated from the evaluation length Wx Maximum depth of waviness motifs: the maximum value of the HWj calculated from the evaluation length

Terms Of Use | Privacy Notice | Cookies | Cookie Settings | About Us | Careers | Careers | Sitemap

Surface roughnessConversion calculator

Represents the sum of the maximum peak height Zp and the maximum valley depth Zv of a profile within the reference length.

Note Rzjis is equivalent to the parameter Rz of the obsolete JIS standard B0601:1994. Although ten-point mean roughness was deleted from current ISO standards, it was popularly used in Japan and was retained within the JIS standard as the parameter Rzjis.

Note This is one of the most widely used parameters and is also referred to as the RMS value. The parameter Rq 7corresponds to the standard deviation of the height distribution. The parameter provides for easy statistical handling and enables stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise.

Motif parameters are used for the evaluation of surface contact status based on the enveloped features of the sample surface.

The material volume and void volume are calculated from a material ratio curve as indicated in the diagram. The position that corresponds to a material ratio of 10% and 80% is regarded as the threshold segmenting the peak, core, and dale.

Note Std represents the angle for the strongest orientation, although the second and third strongest angles can also be defined on the directional chart.

Rms surface roughnessformula

Note These parameters are suited to evaluating the slippage of lubrication mechanisms and contact surfaces, such as gaskets.

Note This parameter concerns height distribution. It is suitable for evaluating the abrasion and oil sump of lubricants for slide planes.

This parameter expands the profile (line roughness) parameter Rp three dimensionally. It is the maximum value for peak height.

Rms surface roughnesschart

This signifies the rate of an increase in the surface area. The increase rate is calculated from the surface area A1 derived by the projected area A0.

This parameter expands the profile (line roughness) parameter Rsk three dimensionally; parameter Rsk, is used to evaluate deviations in the height distribution.

Sk Core height: the difference between the upper and lower levels of the core Spk Reduced peak height: the mean height of the protruding peaks above the core Svk Reduced valley height: the mean height of the protruding dales beneath the core Smr1 The areal material ratio segmenting protruding peaks from the core (indicated as a percentage) Smr2 Areal material ratio segmenting protruding valleys from the core (indicated as percentage)

Rku=3: Normal distribution Rku>3: The height distribution is sharp Rku<3: The height distribution is even

Note This function is used to evaluate friction and abrasion. It is also used to evaluate the lubricity of engine cylinder surfaces.

The horizontal distance of the autocorrelation function that has the fastest decay to a specified value s (0≤ s < 1). Unless otherwise specified, the parameter is specified as = 0.2.

Note Although frequently used, this parameter is significantly influenced by scratches, contamination, and measurement noise due to its utilization of peak values.

Rms surface roughnesstable

Note This is one of the most widely used parameters and is also referred to as the RMS value. The parameter Rq corresponds to the standard deviation of the height distribution. The parameter generates good statistics and enables stable results since the parameter is not significantly influenced by scratches, contamination, and measurement noise.

This parameter expands the material ratio curve parameters (Rk, Rpk, Rvk, Mr1, and Mr2) of the profile parameter three dimensionally.

The average value of the heights of the five peaks with the largest global peak height added to the average value of the heights of the five pits with the largest global pit height.

Note This parameter is suitable for evaluating friction and abrasion. It is also used to evaluate lubricity for engine cylinder surfaces.

Rsk=0: Symmetric against the mean line (normal distribution) Rsk>0: Deviation beneath the mean line Rsk<0: Deviation above the mean line

Rk, Mr1, and Mr2 values are calculated from the linear curve (equivalent linear curve) minimizing the sectional inclination corresponding to 40% of the material ratio curve. Draw a triangle with the area equivalent to the protrusion of the material ratio curve segmented by the breadth of the parameter Rk and calculate parameters Rpk and Rvk.

Note Although frequently used, max height is significantly influenced by scratches, contamination, and measurement noise due to its reliance on peak values.

This parameter expands the profile (line roughness) parameter Rz three dimensionally. The maximum height Sz is equivalent to the sum of the maximum peak height Sp and maximum valley depth Sv.

Note This parameter concerns the height distribution and is suitable for evaluating the abrasion and oil sump of lubricants for slide planes.

Represents the sum of the maximum peak height Zp and the maximum valley depth Zv of a profile within the evaluation length, not sampling length.

Minimum height discrimination: 10% of the Rz value Minimum length discrimination: 1% of the reference length

Surface roughnessparameters

Spc indicates the mean principle curvature (average sharpness) of the peaks. Only peaks that exceed a designated curvature are taken into consideration.

Sku=3: Normal distribution Sku>3: Height distribution is sharp Sku<3: Height distribution is even

This parameter is defined as the ratio of the horizontal distance of the autocorrelation function that has the fastest decay to a specified value s to the horizontal distance of the autocorrelation function that has the slowest decay to s (0 ≤ s < 1) and indicates the isotropic/anisotropic strength of the surface.

Note One of the most widely used parameters is the mean of the average height difference for the average surface. It provides for stable results as the parameter is not significantly influenced by scratches, contamination, and measurement noise.

Parts4laser is not affiliated, associated, authorized, endorsed by, or in any way officially connected with Lumenis their affiliates. Any logos and trademarks of third parties that may be found on our website are registered trademarks of their respective owners. The use of any trademark is for identification and reference purposes only and does not imply any association with the trademark holder.

Pmr The relative material length rate of the primary profile Wmr The relative material length rate of the waviness profile

Rms surface roughnesspdf

The difference in height between the p and q material ratio. Unless specified otherwise, the values p=2.5%, q=50% shall be applied.

This parameter expands the profile (line roughness) parameter Rv three dimensionally. It is the maximum value for the valley’s depth.

Note Rt is a stricter standard than Rz in that the measurement is conducted against the evaluation length. It should be noted that the parameter is significantly influenced by scratches, contamination, and measurement noise due to its utilization of peak values.

Note This parameter is used to evaluate the horizontal size of parallel grooves and grains instead of the height parameters.

Surface roughnesschart

Indicates the ratio of the material length Ml(c) of the profile element to the evaluation length for the section height level c (% or μm).

Ssk=0: Symmetric against the mean line Ssk>0: Deviation beneath the mean line Ssk<0: Deviation above the mean line

Note This is one of the most widely used parameters and is the mean of the average height difference for the average plane. It provides stable results since the parameter is not significantly influenced by scratches, contamination, and measurement noise.

Represents the sum of the mean value for the height of the five tallest peaks and the mean of the depth of the five deepest valleys of a profile within the sampling length.

This parameter indicates the direction angle of the texture (parallel groove orientation, etc.). It is derived from the angle maximizing the angle spectrum of two-dimensional Fourier transformation images.

Note These parameters are used to evaluate the horizontal size and complexity of parallel grooves and grains instead of the height parameters.

Material ratio curves signify the ratio of materiality derived as a mathematical function of parameter c, where c represents the height of severance for a specific sample. This is also referred to as the bearing curve (BAC) or Abbott curve. Probability density curves signify the probability of occurrence for height Zx. The parameter is equivalent to the height distribution histogram.

This parameter expands the profile (line roughness) parameter Rku three dimensionally; Rku, is used to evaluate sharpness in the height distribution.

Pdc The section height level difference for the primary profile Wdc The section height level difference for the waviness profile

Ms.Cici

Ms.Cici

8618319014500

8618319014500