Fresnel lens Definition & Meaning - frenel lens

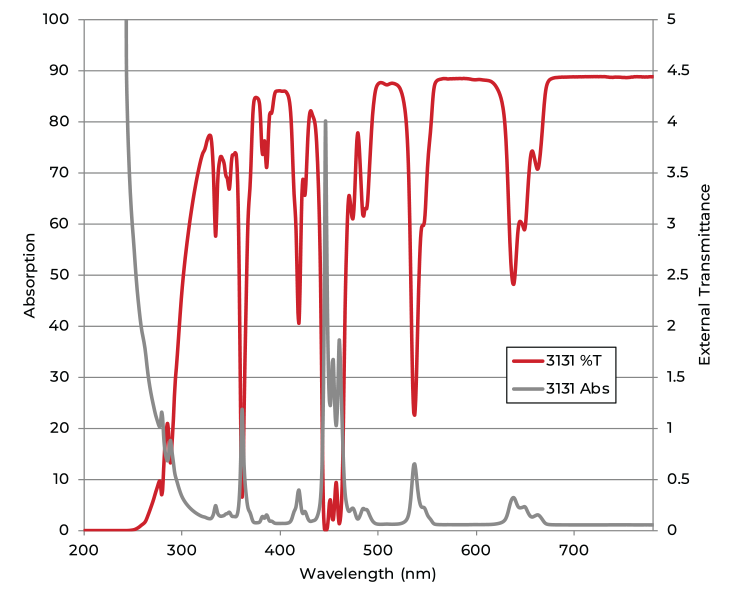

Rare earth glass filters are often used to calibrate the absorption and transmittance of spectrophotometers. These glasses absorb light at very specific wavelengths, which enable the calibration of well characterized absorption peaks across the ultraviolet, visible, and infrared spectrums.

Our IR heaters provide consistent temperatures that can be controlled and monitored easily by operators. Each heater can be programmed with customer-specific recipes, and we can upgrade or alter the controls upon request.

Our engineering team has developed a wide range of heaters, each one consistent with the temperature needs of different manufacturing processes.

As LED adoption increases and replaces conventional light sources, it is important to consider how their light output differs. The image below shows how the spectral power varies between a blue, green, and red LED compared to an incandescent (CIE Illuminant A) source. Colored LEDs have narrow wavelength bands of emitted light which must be considered when designing for specific application wavelengths.

Shortwave irvs swir

Our quartz heating elements maximize the energy that passes through them, providing very efficient heating. They can be found in our Unitube, DuoTube, and Type C+ heaters.

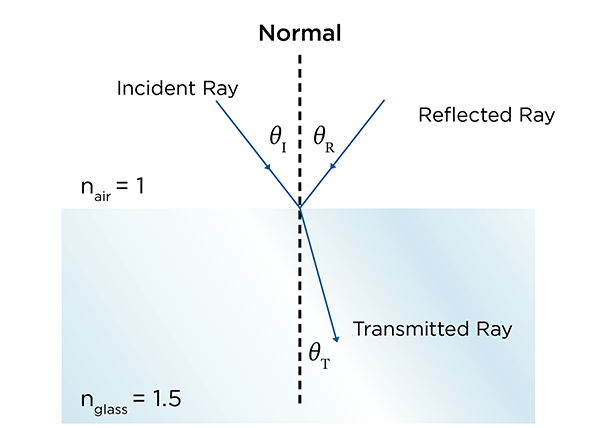

For most glasses with a refractive index of 1.5, reflection losses at the surface result in an approximate 4% decrease in light intensity.

When reviewing a glass property sheet and designing a part, it’s important to know if the industry specifications you’re trying to meet are for external transmission or internal transmittance. For instance, many of the Federal Aviation Administration (FAA) specifications for airport and aerospace applications have requirements that are provided in external transmission. SAE Aerospace Standard AS 25050 requires specific external transmission ratios for the different colored ware. Depending on the transmission level, various grades (A-D) are assigned to the ware.

This is the second article in a three-part series that reviews the thermal, optical, and mechanical properties of glass. We will define common glass properties and explain their application and importance in component design.

It’s important to note that all of the optical properties previously outlined are wavelength dependent. For example, the refractive index of a glass increases as the wavelength of incident light gets shorter. The dispersion of the refractive index is often shown using the example of white light splitting while traveling through a prism. According to Snell’s law, since nblue > nred, light with blue wavelengths refract or change directions more while red wavelengths refract less as they enter, travel though, and leave surfaces of different matter.

Manufacturing cycles often require heat to process materials and produce finished goods. Many manufacturers turn to infrared (IR) heating processes to provide energy efficient, high-intensity heat for various drying applications. More than 60 years ago, Casso-Solar Technologies started out as a simple infrared heaters manufacturer. Since then, weâve continually developed our products to meet the complex, custom specifications of our clientsâ projects.

You’re probably familiar with the concept of “traveling at the speed of light”, but did you know that the speed of light can change? Light’s speed is reduced when it travels through a medium due to the interaction of photons with electrons. Typically, higher electron densities in a material result in lower velocities. This is why light travels fast in glass, faster in water, and fastest in a vacuum. The refractive index (n) of a material is defined as the ratio of the speed of light in a vacuum to that of light in the material.

We deliver cutting-edge production lines to glass manufacturers, backed by decades of experience in glass laminating systems.

At Casso-Solar Technologies, weâve developed infrared heating solutions for over 60 years. We work with each of our clients to ensure they have custom-fitted solutions that integrate with their existing processes and needs, and we partner with each client through the design and implementation process to ensure complete satisfaction. Contact us today to learn more or to get started.

We often hear from engineers who are evaluating the impact of a design change from one lens material to another. For example, they may be switching from an existing polycarbonate lens design to glass due to concerns about durability in harsh environments. They ask “Can I use my existing lens design with the new glass material? Will the resulting light output have the same chromaticity, distribution, and intensity?” The answers to these questions are rooted in understanding the optical properties of materials.

The optical properties of a material determine how it will interact with light. Today, most engineers use advanced software tools to simulate the properties of a material and their impact on optical performance. Still, familiarity with a few fundamental optical properties will help engineers pick the right material for their application. In this article, we review refractive index, transmission, absorption, and wavelength dependency and discuss how these properties impact product design.

Short Wave infrared wavelength

The absorbance of a glass, shown in the figure above as a function of wavelength, is often used to describe the decrease in intensity of light as it travels through the glass. It is defined as

Both short- and medium-wave IR heating systems can heat manufactured goods for processing and finishing, and each one works best for different contexts. Short-wave IR heaters are extremely energy efficient and can reach higher temperatures; the heat can also quickly penetrate objects based on their peak absorption point. Medium-wave IR heaters produce a lot of energy and tend to have a longer lifespan. Our team can help you select the right heating unit based on your manufacturing processes and needs.

The reporting of transmittance values of a material can vary depending on the application or common industry nomenclature. While most industrial glasses report optical properties as external transmittance, values for filter glasses are typically given as internal transmittance. This is because filter glasses may be treated with anti-reflective coatings to prevent intensity losses at the glass surface. For example, a glass filter which has an external transmission of 92% at 589.2 nm might have a much higher internal transmittance of 0.98, as is the case with our 3131 filter.

Medium-wave infrared heating solutions radiate heat with longer length-waves. Our DuoTube heating unit can reach high temperatures of up to 1400°F or 1750 °F, depending on the coating or refractory selected. The gold-coated DuoTube has a dual-coat integral gold reflective coating, which does not oxidize and can reach temperatures of up to 1400°F. The white refractory DuoTube works on a wider emission spectrum and can reach temperatures of up to 1750°F. Both types are completely maintenance-free throughout their useful life.

When a beam of light hits a glass surface, part of the beam is reflected and part is transmitted. The index of refraction of the glass determines not only how much light is reflected and transmitted, but also its refracted angle in the glass. The angle of transmission can be calculated using Snell’s law:

The luminous intensity distribution on the right is from a glass lens with a typical refractive index of 1.5.Displayed on the left, a lens with a refractive index of 1.6.It could be made from a higher index of refraction glass or plastic, such as polycarbonate. For an application that requires light illumination across a larger surface area, it may be better to choose a glass with a smaller refractive index. Or for instance, you want to obtain more intensity closer to the center of the candela distribution; you would choose a material with a higher refractive index. Understanding this optical property will provide you with one more tool to help you select the right material and achieve your desired performance results.

To help you design better-performing glasses lenses, we created a comprehensive eBook that includes more than 40 pages of information on the thermal, optical, and mechanical properties of glass.

SWIR camera

As a New Product Development Engineer, Mike develops a strong understanding of customer needs and works with the Kopp Glass commercial and technical teams to provide innovative solutions in the forms of molded glass. Mike is a Pittsburgh native and graduate of The Pennsylvania State University where he earned a B.S. in Engineering Science and Mechanics and a B.S. in German. He has four years’ experience in thin film organic electronics and five years’ experience in automotive glass product development. He enjoys exploring Pittsburgh and the surrounding areas while jogging, hiking, biking, and skiing with his friends and his wife, Mallory, and their dog, Rocky.

Short Wave Infrared sensor

In some applications it is beneficial to reduce light output in equal parts across all wavelengths. Neutral density filters, for example, absorb all wavelengths nearly equally and are often used in photography to reduce the intensity of light without affecting the color. They’re also used to attenuate lasers and other light sources where the power can’t be adjusted or reduced.

If you want to learn how to design glass lenses and components that are optimized for both your performance requirements and operating environment, download our free eBook.

So far in this series we’ve discussed thermal and optical properties of glass and their impact to product design. These are just two elements of successful design. Our final article in this series will explore the mechanical properties of glass, which are especially relevant when products are used in harsh environments or are subject to corrosive chemicals.

When designing a lens that transmits light, it is necessary to consider the material’s refractive index. Even a small change in the refractive index can affect the candela distribution of the transmitted light. This can be seen in the example below, where light travels through two identically shaped plano convex lenses with different refractive indices.

SWIR camera price

External transmittance includes both the absorption loss of the material and the loss of light due to reflection at the two glass surfaces, while the internal transmittance only includes absorption losses of the material.

Shortwave irapp

If you need uniform heating throughout your materials, we provide flat panel infrared heaters featuring heating elements bonded to refractory that can handle high heat.

Manufacturers must consider both the efficiency of the infrared heat itself and the heat absorption factor of the material being processed. As a more intense heat source than convection heat, infrared heat should be applied directly to your process materials within the processing chambers of an oven or dryer. The ovens help control the timing and amount of heat applied to avoid product damage or overheating. Consult our infrared heating specialists to determine the best way to apply infrared heat to your project.

The reflection, absorption, and transmission of a glass also vary with wavelength. The color of a glass is determined by the wavelengths that the glass absorbs and transmits. For example, a glass that absorbs green, yellow, and red wavelengths and transmits blue wavelengths will appear blue to the eye. Chromaticity is something we know a lot about and will discuss in greater detail in a future blog article.

For example, if you are designing optical prisms or other features of a lens, it is critical to choose the correct index of refraction. As previously mentioned, the index of refraction changes with wavelength, so it may be necessary to address any index changes and design optical features that work across the spectrum with LEDs that range from blue to green to red.

Medium-wave IR heaters produce a high level of energy and can last longer than their short-wave counterparts. They are ideal for drying operations and handling water-based coats, as water can easily absorb medium-wave energy. However, these heaters have alower power density than short-wave heaters and thus require a larger footprint to deliver the same amount of energy.

Larger indices of refraction in glass result in greater differences between the angle of incidence and transmission of light. The reflection of light at the surface occurs due to an instantaneous change in refractive index between glass and its surrounding medium. For normal incidence (Θi = 0°), the amount of light reflected is found by

Learn more about how infrared heating works, the differences between short-wave and medium-wave infrared heaters, and their respective pros and cons.

SWIR wavelength range

Short-wave infrared heaters offer a lot of heating power. The shorter wavelengths can increase the amount of energy absorbed by the heated objects, and short-wave heaters can reach higher temperatures than medium-wave heaters. However, the higher operating temperatures of short-wave heaters can lead to shorter equipment lifespans over time.

Short-wave infrared heating systems use short waves, which give off more energy and operate at higher temperatures. As a result, these heaters offer high-intensity heat that can reach 5000°F or higher. Our Casso-Solar SWL Unitube Heater can radiate waves between 0.76 and 2.0 microns, and operators can control the wavelength to align with the peak absorption point of process materials. Each unit includes controllable emitters that can be shut down to preserve energy, modified for temperature profiling, and more.

IR heaters provide radiant heat without relying on the ignition or combustion of energy sources that can produce contaminants, toxins, or on-site emissions.

Our electric IR heaters are extremely efficient with their power consumption. For instance, our DuoTube heaters feature an integrated ceramic coating reflector to ensure that most of the infrared energy generated is directed at the product.

Short Wave infrared vs near infrared

When light travels through a glass, the intensity of the light is typically reduced. This absorption happens when the energy of a photon of light matches the energy needed to excite an electron within the glass to its higher energy state, and the photon is absorbed by the glass.

here A, B, and C are constants specific to the glass composition. This relationship works well for visible wavelengths, but often does not accurately describe ultraviolet or infrared behavior.

Any light that is not absorbed by a glass or reflected at its surface will be transmitted through the glass. It is often very important to know exactly how much light will pass through a glass at specified wavelengths. Often, glasses are discussed in terms of their transmittance or transmission. The same information is provided by both of these terms but transmission is reported with ranges from 0 % to 100 % and transmittance from 0 to 1.

As a New Product Development Engineer, Mike develops a strong understanding of customer needs and works with the Kopp Glass commercial and technical teams to provide innovative solutions in the forms of molded glass. Mike is a Pittsburgh native and graduate of The Pennsylvania State University where he earned a B.S. in Engineering Science and Mechanics and a B.S. in German. He has four years’ experience in thin film organic electronics and five years’ experience in automotive glass product development. He enjoys exploring Pittsburgh and the surrounding areas while jogging, hiking, biking, and skiing with his friends and his wife, Mallory, and their dog, Rocky.

Casso-Solar only uses high-quality components in our electric IR heaters, meaning that they require little to no maintenance throughout their useful life, which lasts tens of thousands of hours.

Infrared heating is a reliable, basic heating method that integrates well with a myriad of manufacturing processes. The infrared energy wavelength of an object depends on its temperature. The higher the temperature an object produces, the shorter its energy wavelength, resulting in a higher output of energy. Infrared radiation is electromagnetic energy that is categorized as short-wave,medium-wave, and long-wave infrared, with short wavelengths providing the highest energy output and long wavelengths having the lowest. Long-wave or beyond long-wave infrared can be too inefficient for industrial heating processes, so they generally are not used.

Ms.Cici

Ms.Cici

8618319014500

8618319014500