Freewell UV Protection (Ultraviolet) Filter 95MM for ... - ultraviolet lenses

The process of designing and building a camera may seem daunting, but with a bit of patience, the help of this guide, and some further reading, you’ll be able to do it. You can use this information to figure out what you want to build, gather some simple materials and tools, and build it!

IRtransparentplastic

A pinhole camera is the simplest possible camera. Light rays reflect off objects in all directions, and the lens on a camera re-aligns them so that they meet at the same spot on the film when the lens is correctly focused. Instead of a complex arrangement of glass lenses, the pinhole camera uses the simplest optics: a tiny hole that blocks almost all of the light rays except for the ones already aligned correctly. A mechanically timed shutter is replaced with anything that can cover the pinhole when the camera is not taking a shot.

Then, use some 600-grit sandpaper to sand away the protruding metal on the opposite side. If you have a microscope or a flatbed scanner, you can inspect the pinhole roundness and quality. You can buy special carbide micro drills, but you need a high-speed drill press to use them.

Thankfully, there’s a solution. use a chart to estimate the extra time needed. There is one attached above and you can print it out and bring with you when shooting until you have enough experience to make estimates without its help. Your film’s datasheet will have a section on its reciprocity characteristics and can be found online.

There are loads of apps on both android and apple that cover reciprocity failure. Most have detailed charts for most film stocks too. Dunno about windows phone as I’ve only ever used android and apple.

Designing a pinhole camera is a relatively simple and straightforward process. The first thing that you need to do is to make or buy a pinhole. If you want to make your own pinhole at home, you need a thin piece of metal. A good material to use is the metal from the side of a pop can. Alternatively, you can use aluminum foil. The thinner, the better, as long as it is light-proof. Use scissors to cut out your tin and a pin and a hammer to gently poke a hole through it. Use an eraser or something soft to support the aluminum to stay flat when pressed on.

Pinhole exposure is not an exact science, so you don’t need precise math. This is the kind of thing you’ll have to calculate out in the field, so doing it in your head semi-accurately is acceptable. No need to bring a calculator. So, if the pinhole is f221, lets round to f256 to make life easier. If we count backward to f16, there is a difference of 8 values. This means the amount of light through an f16 aperture is 28 times more than f256. This just so happens to be 256. This means that when we take a digital camera or light meter, set the ASA/ISO to the speed of the film in the camera, set the aperture to f16, and get a shutter speed; we multiply it by 256. For example, if we measure a value of 1 second, we will need to expose for 256 seconds to get enough light.

Esco Optics is a leading manufacturer of custom and catalog optics, precision optical components, and ITAR optics in the United States.

Magnesium fluoride (MgF2) is also a crystalline material that transmits well from the UV through the MWIR spectral bands (0.1 to 7.0μm). Magnesium Fluoride has relatively low cost; however, is thermally sensitive and requires special handling considerations.

What istransparent to infraredlight

We love it when our readers get in touch with us to share their stories. This article was contributed to DIYP by a member of our community. If you would like to contribute an article, please contact us here.

Once you determine (or already know) the pinhole diameter, you can calculate the focal length of the camera. The formula is: focal length = (pinhole diameter / 0.03679)2. The focal length is the distance that the pinhole should be from the film.

When dealing with the infrared region, it is important to know this part of the electromagnetic spectrum breaks down into further sub-sections.

Material transparent to infraredradiation

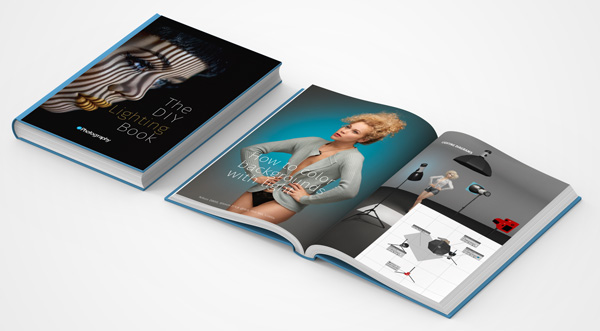

Established in 2006, DIYP has been at the forefront of the industry for over 15 years, providing our readers with the latest news, insights, and inspiration.

If you enjoy taking film photos (and want to try pinhole photography), you know the satisfaction you get from a film photo that you just don’t feel when you use digital. Just imagine seeing the first photo you get out of a camera you designed and built yourself!

The f-stop values have certain cornerstone values, and the difference between these values is that the amount of light allowed through is halved each time. Essentially, the area of the circle formed by the aperture is halved each time, and thus the light. These values are as follows; 1.4, 2, 2.8, 4, 5.6, 8, 11, 16, 22, 32, 44, 64, 88, 128, 176, 256, 352. Anything past f22 is going to be unavailable on a light meter, so here’s how we are going to determine a multiplication factor for the pinhole.

Matt Bechberger is a photographer and a maker from Canada. You can follow his Flickr stream here and his awesome Instructables here.

If all that calculating seemed straightforward, unfortunately, it’s more complex than that. When exposed for a short period of time, the film’s response to light is linear. Expose the film for twice as long, and the film will react twice as much to the light. However, if you begin exposing for more than a few seconds, the film stops responding linearly. It actually takes a lot more light than you would expect. This is called reciprocity failure, and it happens with all films.

This angle of view information is crucial to determining if the pinhole, at its focal distance, will cover the film appropriately. Too little coverage and the result will be a circular image with black corners and edges. The diagonal of the film frame needs to fit inside the diameter of the coverage. The formula to determine the image diameter is:

Your first example uses 0.03679 in your calculation to obtain focal length. What does this number represent? Is it the film diagonal?

We got your attention, didn’t we? There is a great Instructable going into depth (yes, even more than here) on some of the aspects. Matt also wrote it, so expect great explanations, high-end math, and laser cutting.

Germanium (Ge) is a grayish non-transparent crystalline material and one of the most commonly used infrared materials. It is an optimal material for night vision and thermal imaging systems in the MWIR and the LWIR band. Germanium transmission performs best between 8 and 12µm. Ge has a low optical dispersion and a high refractive index which makes it an ideal solution for a wider field of view lenses. Its crystal structure is similar to diamond and when a DLC coating is applied (Diamond Like Carbon), it becomes very durable against outdoor elements and harsh environments.

There needs to be a hole in the back of the box to read the film frame numbers off of it. Keep in mind that you should paint the inside of your pinhole camera black to absorb any stray light.

Using the example of a 256-second exposure, the reciprocity factor is approximately 4x for that length of exposure, so 256 seconds turns into 1024 seconds. Four minutes to 17 minutes, what a huge difference! Of course, this is all just for “ideal” exposure. A few minutes less or more won’t hurt anything. In fact, I exposed my first test roll only 1/8th as long as I was supposed to, and it came out looking pretty good.

A shutter mechanism can be as simple as a piece of tape stuck over the pinhole attached to a pivoting piece of wood. You can also build a more complex spring-actuated sliding shutter with a shutter release cable thread. I built one which could be actuated by shutter release cable, and a spring holds it shut.

Material transparent to infraredwavelength

Sapphire crystal (Al2O3) is an optimal choice due to its mechanical strength, scratch resistance, and its hardness which is second only to diamond. It is used in ultraviolet (UV) and visible wavelengths beginning around 150nm and also performs well in IR to around 5µm. The downside to sapphire is the high material and processing costs.

As the leader for military and defense optics in the United States, Esco Optics adheres to the International Traffic in Arms Regulations.

Infrared transparentmaterials chart

I want it to be clear that building a pinhole camera relies on your abilities, available materials, and your desired outcome. As a result, this guide is less of a step-by-step and more of a lesson on how pinhole cameras work, the physics and math involved, and some practical knowledge I gained while researching and building my own cameras for pinhole photography.

The next value you need to calculate is the view angle of the pinhole. This angle is the maximum angle that a ray of light can make through the pinhole. The controlling factors of this value are the hole’s diameter and the material’s thickness. I know, this all seems like a lot of math and extreme precision, but bear with me. All of this will help you get your pinhole photography to perfection.

Zinc selenide (ZnSe) is another common material that is used in both visible and IR (MWIR & LWIR) from 0.45 to 21μm. It is a light-yellow solid compound comprised of zinc and selenium. It is very similar to zinc sulfide, but has a slightly higher refractive index and is structurally weaker

I remember me teacher making me make a pinhole camera before I could use my brownie. When I graduated I had two Sinars and an old deardorf. I ended up working in a commercial lab as a mural printer. My DeVere was on a train track

It comes from Petzeval’s formula which relates the focal length to the diameter of the hole and the wavelength of the light. This old article is incorrectly tagged as “comprehensive” but it’s clearly not that. There is more detail on the calculations involved over at Wikipedia.

ITAR registered and compliant, Esco manufactures ITAR optics for all of its customers with the strictest confidentiality.

Obviously, no other camera or meter is going to allow f/221 as an option, so we need to make some calculations to find out how to do an equivalent exposure time from something that we can measure.

The next value that can now be determined is the equivalent f-stop. The f-stop value is a relationship between the diameter of the pinhole and the distance to the film. This number is valuable for calculating the exposure time required for taking a photo in pinhole photography. The formula is:

In this example for calculating image diameter, the diameter has come out very large, meaning that combined with a curved film plane, it will allow for a 6cm tall by 17cm wide image to be taken on 120 film. This will produce a very panoramic and extremely wide view.

Material transparent to infraredlight

In conclusion, there are many material options available for infrared capabilities and whether you need a IR windows, lenses, or freeform optics, we are available to help you find solutions to your objectives. Our manufacturing team can fabricate windows, prisms, lenses, aspherical lenses, and prototypes all in-house. Please reach out to us on your next project today at sales@EscoOptics.com.

Infraredplastic

Wow! You really inspired me to build one myself now – Sad enough only that pinhole-day is this sunday and not the next ;)

You can make the camera from a pre-existing box or build one from scratch. You can use any material, even something silly like oranges, a potato, or LEGO bricks – as long as it doesn’t allow light leaks. I’d start with a wooden box though. You can use a metal rod with one end filed flat and a guitar knob to create a film advance handle. You need two: one to loosen the supply spool and one to tighten the take-up spool.

IR fused silica is virtually free of OH-ions providing superior transmittance at the 2.7μm wavelength “water band” region where standard UV grade fused silica absorbs light. The low OH content (<1 ppm) expands the overall usable range of fused silica to 3.6 microns. As with other fused silica designations, IR grade also shares the same outstanding homogeneity, bubble characteristics, low coefficient of thermal expansion, and chemical resistance.

Is silicontransparent to infrared

Once the math of the camera design is complete, the physical design and building can begin. The film and pinhole are placed parallel to each other, and the distance between them should be equal to the focal length. Utilizing a curved film plane allows the entire length of the film to be exactly the correct and consistent distance from the pinhole to ensure an even exposure for the best pinhole photography results.

Custom IR windows are popular because they allow for the transmission of infrared light while providing protection to sensitive infrared sensors and systems. IR windows, stepped windows, lenses, and other precision optics made from materials such as calcium fluoride, germanium, magnesium fluoride, sapphire, silicon, zinc selenide and zinc sulfide, which are highly transparent in the infrared spectrum and possess excellent durability and thermal stability. IR precision optics are ideal for a range of applications, including thermal imaging, spectroscopy, and environmental monitoring. Their ability to withstand harsh environments while maintaining high optical performance ensures accurate and reliable measurements in various industrial, military, and scientific settings.

If you are seeking to build a camera without all the math behind it, check out our Pinhole photography section, there are lots of goodies there, like 23 pinhole cameras you can build at home. If it is a challenge that you are seeking, go after The Battlefield or the La Guillotine – very complex but also very rewarding.

Esco Optics, Inc. 95 Chamberlain Road, Oak Ridge, New Jersey 07438 Tel: 1-800-922-3726 | Fax: 1-973-697-3011Sales@EscoOptics.com

Dunja Djudjic is a multi-talented artist based in Novi Sad, Serbia. With 15 years of experience as a photographer, she specializes in capturing the beauty of nature, travel, and fine art. In addition to her photography, Dunja also expresses her creativity through writing, embroidery, and jewelry making.

There is another group of materials that perform well in the IR but require a high amount of safety precautions during manufacturing due to their harmful material makeup. Chalcogenide glass is a glass containing one or more chalcogens (sulfur, selenium and tellurium, but excluding oxygen). Such glasses are covalently bonded materials and may be classified as covalent network solids. Chalcogenide glass remains amorphous while exhibiting optical transparency over the full IR region of 2-20µm.

Obviously, with shutter speeds this long, you’ll always need to use a tripod and not touch the camera over the duration of the exposure. Keep this in mind if you’re building your own pinhole camera, so you can add tripod mounts.

Zinc sulfide (ZnS) performs best between 8 to 12µm region. Although a lower cost relative to ZnSe, it does not have the longer transmission range. As a strong and stable material, ZnSe has high resistance to particulate abrasion making it an ideal solution for IR windows on aircraft platforms.

Calcium fluoride (CaF2) optics are ideal for a broad range of Ultraviolet (UV), Visible, or Infrared (IR) applications. Its low refractive index reduces the need for anti-reflective coatings. Its application ranges from thermal imaging systems to excimer lasers making it a very versatile material for ultraviolet (UV) to infrared (IR) frequencies.

Silicon (Si) is a crystalline material like germanium primarily used within consumer electronics for microchips, as well as, extensive use in the semiconductor industry. Silicon is an excellent choice for windows and lenses in the 3μm to 5μm MWIR spectral bands for use in imaging, biomedical and military applications. Silicon optics are more heat resistant than germanium ones, as operating germanium in temperatures higher than 100°C leads to reduced optical properties.

If you don’t want to bother, you can buy pinholes from eBay or a few other specialty websites. Google will find an up-to-date list of locations.

NIR and SWIR together are sometimes called "reflected infrared", whereas MWIR and LWIR are sometimes referred to as "thermal infrared".

Ms.Cici

Ms.Cici

8618319014500

8618319014500