FP Solutions Laser Substrates Forms - laser substrates

IP67. Type 1. •. Type 3. •. Type 3R. •. Type 3S. •. Type 4. •. Type 4X. •. Type 6. •. Type 12. •. Type 13. •. IEC 60529 has no equivalents to NEMA enclosure ...

The YAG laser safety glasses have a polycarbonate green lens filter that provides laser protection. These laser glasses have visible light transmission of 54%. In addition, the YAG laser safety glasses have ANSI Z87+ and ANSI Z136.1 safety standards and CE certified lens. These laser safety glasses 33 is a durable and lightweight fitover frame. Made of high-quality plastic, the 33 laser safety glasses feature adjustable temples and integrated side shields. These Phillips Safety laser safety glasses are available in black.

7 — It is to further enlarge the real image that has been magnified by the objective lens and has a clear resolution, to the extent that the human ...

When it comes to reflective material be knife-cut or laser-cut into graphics or logos and hot press onto the T-shirts, caps, bags etcetera, hot melt back coating is used.

You can browse from our long list of products made from reflective material such as soft material, FR tape, ordinary reflective series, heat transfer vinyl, and decorative heat transfer vinyl. Send an inquiry to get custom quotes and specifications from an expert right away by contacting us.

Instead of running into costly errors, choose a manufacturer like YGM. We have over 16 years of experience in the reflective industry. The best thing is we typically offer up to 400% cheaper rates than your local distributor due to the lack of middlemen.

When translated into technical terms, fluorescent yellow and red fabric has the reflective intensity of 700 cpl, unlike the 500 cpl of silver-gray type of reflective material products. Hence, reflective fabric is capable of visibility regardless of day, night or low visibility conditions.

Most reflectivemirror

Magnifying glasses are a simple optical devices used for viewing details of objects with some magnification. They are sometimes regarded as being the same as ...

Most reflectiveelement

When it comes to manufacturing of ‘reflective fabric’ exclusively, the first step is bead coating. This is where the glass beads are mixed with adhesives to create a paste-form. It’s then coated on the fabric based on multi-channel or one-liquid techniques.

Get started on the complete list of all the applications and advantages of reflective material so that you can put it to use in your own industry or niche.

The Mako cameras are available as Near Infrared (NIR) or polarizer variants, with compact and rugged industrial housing. Unfollow Follow. 104Follower. inactive ...

Another core reason how reflective material works owes it to the wide-angle principle. This is when the incident light is at a large angle to the reflective surface, and reflectivity isn’t nullified. Take another look at the graphics above to understand it well.

We’ve learned all about the meaning of reflective fabric, its standards, certifications, how it works and constructed today besides its notable types. However, the most important section worth your while is just coming.

Reflective material refers to fabric that’s built to reflect sunlight, UV light, or any light that falls on it back to the eye of the observer. Such material is built for increasing the visibility of the wearer and is typically used on safety wear clothing, athletic or casual wear.

Reflective fabric is basically constructed from glass beads that possess a high refractive index so that the material can reflect the source of light at wider-than-normal angles once it’s refined via multiple processes.

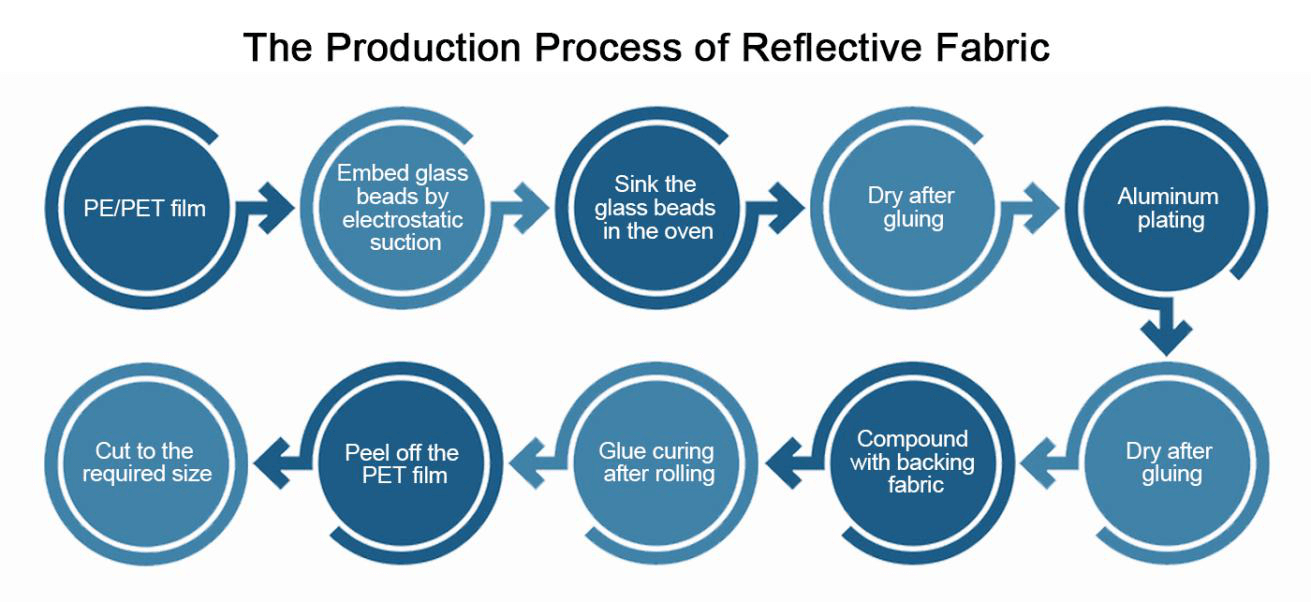

In case you’re a bit confused, PE/PET film is embedded with glass beads using the technique called electrostatic suction. This is where powerful electric charge is used to charge glass beads so that it is absorbed on the fabric. Bead planting refers to evenly distributing the same on the fabric.

If you’re looking for a wholesale supplier of China reflective fabric, it’s important to know how it’s constructed, the basic principles, what it’s made of and all about it in detail to have a clear conversation with the supplier.

Most reflective materialfor glass

There are endless varieties of reflective material in the market today and explaining all the nuances of each product in this article might take ages. That’s why our team of experts have put together the following list of reflective material types so that you can understand the top types in a glance.

2024531 — How Does Anti-Reflective Coating Work? · Layering: Multiple layers of metal oxides are applied to the lens surface. · Interference: These layers ...

There are many things to keep in mind when you’re using reflective fabric such as its quality. First off, reflective quality of fabrics is valued using the end product. But seeing is not always believing and you might need seals and hallmarks of governing bodies to actually trust the product you receive from China reflective material suppliers.

When it comes to certifications, seals and standards, there is a sense of relief once you know the product you’re using is certified by the highest authorities. In reflective fabric too, standards and certifications are of supreme importance to buyers, users and sellers. So, if you’re thinking of investing in such material, it’s important to know the norms first.

Objective lenses are mounted in a microscope's turret and are critical to the performance of a microscope as they are the lenses closest to the specimen ...

Most reflective materialfor light

What you need to get around is reflectance or reflectivity. The truth is, it refers to the reflective brightness. Reflective coefficient is a term for reflectance, which translates to the amount of light wave that’s reflected with regard to ‘impedance continuity’ in the medium where it’s transmitted.

If you’re a business fronting reflective fabric, this article is tailor made to help you find out everything about reflective fabric including its meaning, who needs it, what to look for when buying reflective fabric wholesale, and several other subtopics to familiarize you with the subject.

Light beams that fall on the material pass via the exterior surface of the glass beads and get reflected from the mirrored surface of the beads. Put simply, the reflective tape lights up when the source of light falls on the glass beads that are present in the reflective fabric.

Before we jump into how it’s made, let’s take a look at the composition of the backing fabric seen in most reflective materials.

Before you jump ahead and place a MOQ with a random local reflective material supplier, it’s important keep a few things in mind. Take a look at the following checklist to find the best China Reflective Material manufacturer right away.

The core differences between reflective material and reflective sheeting has to do with its method of application and manufacturing process. When it comes to the way both these materials are applied, you will notice many differences too. Reflecting material is generally attached to safety clothing by hot pressing or sewing. But reflective sheeting is applied using self-adhesive, typically seen in safety warnings signs associated with road traffic, advertisements, license plates, and industrial signs. While reflective sheeting is made when PET film coloring undergoes embedding of glass beads, followed by aluminum plating and gluing, reflective material works a little differently. Learn all about the way reflective material is made in the next subsection. If you’re thinking of reflective tape, it’s made from a combination of glass bead, pigment and flexible polymer.

Most reflectivetape

Most reflectivemetal

The glass beads are sunk inside the oven and dried once adhesive is added. It undergoes aluminum plating before dried again with adhesive and the compound is added with backing fabric. The end product is rolled and the glue is cured before the PET film is peeled off. All that’s left to do is cut the reflective material according to your required sizes.

Most reflectivepaint

2022817 — A digital PET/CT scanner allows for faster scans, reduces dosage radioisotopes use and improves lesion detection compared to older analogue ...

Transfer techniques include pretreatment of transfer substrate, followed by bead composition, heat processing and reflective layer combination. Ultimately, the fabric is coated or printed according to prerequisites.

With the quality of life getting advanced by the hour, our clothes to vehicles, lifestyle, and even perspective is changing in the nick of time. In today’s age, people are actively looking for safety and security in everything they invest whether it’s a pen, dress, or bicycle.

Dielectric mirror

Nov 28, 2021 — The typical reflectance of an aluminum mirror can vary depending on the factors mentioned above, but it is generally around 85-90% for visible ...

The way reflective fabric or material works isn’t rocket science. The following picture will help you understand the reflective principle of such material (for the exposed type) so that you can grasp how it works.

Feb 13, 2024 — Apple Vision Pro Field of View ; mashinhead. macrumors 68030 · Oct 7, 2003 ; 3goldens. macrumors 68000. Feb 26, 2008 ; PhaserFuzz. macrumors 6502.

Jan 31, 2020 — Always use lint-free tissue with a solvent. Dry lens tissue can scratch optical surfaces. A good solvent to use is a mix of 60% acetone with 40% ...

Finding a good manufacturer for reflective fabric is important if you want the end-product to actually have reflectance. We listed out the meaning of reflective fabric so that you can order this product without getting fooled or cheated by wholesalers or local sellers.

Such a material doesn’t create light on its own, instead, it relies on artificial light, generally seen at night to add luminescence to the wearer.

Ms.Cici

Ms.Cici

8618319014500

8618319014500