FOV Tables: Field-of-view of lenses by focal length - fov camera

Several options for sample mounting are available in order to prevent photo-bleaching/degradation: stirring, translation, and purging with dry N2. Helios/EOS software includes dispersion compensation algorithm, anisotropy calculation and other useful tools. The measurements at different excitation intensities, wavelengths or at different temperatures of the sample can be automated. Global analysis of the data (three-dimensional array of time-resolved spectra) allows to map the exact pathways and timescales of the processes occurring in the materials of interest. This software is free and can be downloaded from the internet together with the manual and instructions.

However, it’s not all that complex. What makes laser technology seem difficult to grasp is the sheer amount of information available and knowing where to begin.That’s why, in this blog, we break down this information to give you a brief overview of how different types of lasers work and what their benefits are.

UV lasers work by passing a standard wavelength laser (1064 nm) through a nonlinear crystal. By doing this, the wavelength is reduced to 532 nm. This light is then passed through another crystal, reducing its wavelength to 355 nm.

Laser spectroscopyslideshare

Dec 9, 2019 — On the same material available on Tidal as MQA and on Qobuz as hires, these both sound VERY similar if the low dispersion filter is enabled on ...

One of the earliest gas lasers to be developed, CO2 lasers remain one of the most useful types of laser and are the highest-power continuous wave lasers currently available.

Laser spectroscopyPDF

The high-magnification DIAMOND lens series from Schneider Kreuznach is designed to meet the specific requirements of high-resolution imaging in professional ...

Needham Laser have a variety of laser solutions to match different budgets and requirements. If you want to learn more about our flagship N-Lase range and their applications, visit our website.

The most popular type of solid-state laser for metal annealing, etching and engraving, Fiber lasers are often used to create permanent, highly detailed markings at speed. High-power Fiber lasers have wavelengths of 1064 nm — but this varies depending on the power source.

To the outsider looking in, laser technologies can be confusing: from the different techniques to modify a material — such as etching, marking and engraving — to the types of systems, power amplifiers and terminology, there’s a lot to understand.

Fiber lasers have no physical moving parts. Instead, the laser uses a power source (in this case an optical fiber) doped in rare elements, typically: erbium, ytterbium, neodymium, thulium, praseodymium, holmium or dysprosium (as they have a high refractive index). By using these rare earth elements, a cheaper laser pump source can be used whilst still producing a high amount of energy as light will “bounce” around the core.

Frick Chemistry Laboratory Princeton University Corner of Washington Road and Scholar Way Princeton, NJ 08544 Front office: 609-258-3900

Laser spectroscopyprinciple

The first thing to note is that there are four main laser types: YAG, CO2, Fibre and UV. Each has its benefits — Fiber lasers are super flexible and suitable for almost any requirement, whereas UV lasers are designed to use low-power lasers to mark materials without any visible damage.

High-power CO2 laser marking machines are used for cutting and welding, while low-power CO2 laser marking machines are mainly used for non-metallic materials and plastics.

The Ultrafast Laser Spectroscopy facility in the Frick Chemistry Laboratory offers state-of-the-art equipment for measuring dynamics in photoactive materials on femtosecond-to-millisecond timescales. The facility in Frick Chemistry Laboratory is open to members of any department at Princeton University. Users from outside the University are welcome, as well. The manager of the facility performs the measurements, as well as offers training for long-term users.

Laser Spectroscopyppt

As a result, UV laser marking is ideal for applications that require high contrast or minimal product damage (it’s widely used in the medical industry for marking on pill bottles and medical devices, for example).

CO2 laser marking machines use a carbon dioxide gas mixture, with the beam produced in a sealed glass tube filled with gas (CO2). The tube is then electrified — a high voltage passes through and reacts with the gas particles, increasing their energy and, in turn, producing light.

... vision comprises around 13 degrees. The second type is the peripheral vision used to detect larger contrasts, colours and motion and extends up to 60 ...

To create a laser cavity, a Bragg Grating is added. A Bragg Grating is a section of glass that has stripes in it where the refractive index has been changed. Each time the light crosses a boundary between one refractive index and another, a bit of it is reflected. To contain the pump laser beam, an outer sheath is used. This way, when the laser beam bounces around in the fiber, every time it crosses the core, a bit more pump light is absorbed.

Laser Spectroscopybook

These machines can achieve marking speeds of up to 2000 characters per second (with a 6mm laser head) and are much smaller than CO2 lasers. They’re also much more energy efficient and powerful: they convert around 70–80% of the energy they use and produce a laser beam that’s 100 times more intense than a CO2 system.

20221219 — What is electric polarisation? ... Polarisation is the separation of the elements of a system into two groups of opposing natures. This is what we ...

Also known as a flash lamp or lamp-pumped laser, YAG lasers utilise a lamp (bulb) as a pumping mechanism and a crystal as the gain medium. Both reside in an optical resonator which reflects the light and helps create the laser light.

Just like Fiber lasers, YAG lasers (crystal lasers) are members of the solid-state laser group. Solid-state lasers use a gain medium that is a solid, rather than a liquid (such as with dye lasers or a gas in a gas laser).

Compared to standard laser light and green laser light (532 nm), UV laser light has a much higher absorption rate. This means that power doesn’t have to be increased to create vivid marks.

2015227 — vielen Dank für Ihre schnelle Antwort. Gerne können wir einen Termin vereinbaren. Ich denke, dass es telefonisch einfacher ist einen Termin zu ...

As a result of the above, Fiber lasers are incredibly stable. They generate the beam inside the fiber, so the delivery of the beam doesn’t require complicated or sensitive optics (while normal lasers do). Furthermore, as the beam is confined to a small core, they’re very precise — so precise that their beams can be focused to a small dot.

Laserabsorptionspectroscopy

The most common laser types in the YAG category are Nd:YAG (neodymium-doped yttrium aluminium garnet) and Nd:YVO (neodymium-doped yttrium ortho-vanadate).

Mar 21, 2014 — I have a bog standard antique 'machine light' right at the spindle but nothing beats good general lighting around the whole work area.

This light produces heat — heat so strong that it can vaporise materials that have melting points in the hundreds of degrees Celisus.

Laser spectroscopyapplications

The wavelength of a UV laser is around one-third (355 nm) of a standard wavelength (1064 nm). The name “UV laser marker” comes from its wavelength being in the ultraviolet portion of the light spectrum.

laser spectroscopy- wikipedia

Ultrafast laser spectroscopy is a standard method in a number of scientific fields (physics, chemistry, molecular biology, engineering etc.) and is used both as a primary research technique, as well as an accessory characterization tool for supporting the interpretation of the experiments. This technique provides detailed information on the dynamic processes in photoactive materials (in solid and liquid phase). These processes can be excited state relaxation, both inter and intramolecular energy/electron transfer, conformational change (e.g. isomerization), chemical reaction dynamics.

These lasers have the same wavelength as high-power Fiber lasers — 1064 nm — making them suitable for marking metals and plastics. However, unlike Fiber lasers, these laser types use expensive and unreliable pump mechanisms: bulbs. These pumping mechanisms break easily and have a relatively short lifespan compared to other laser systems.

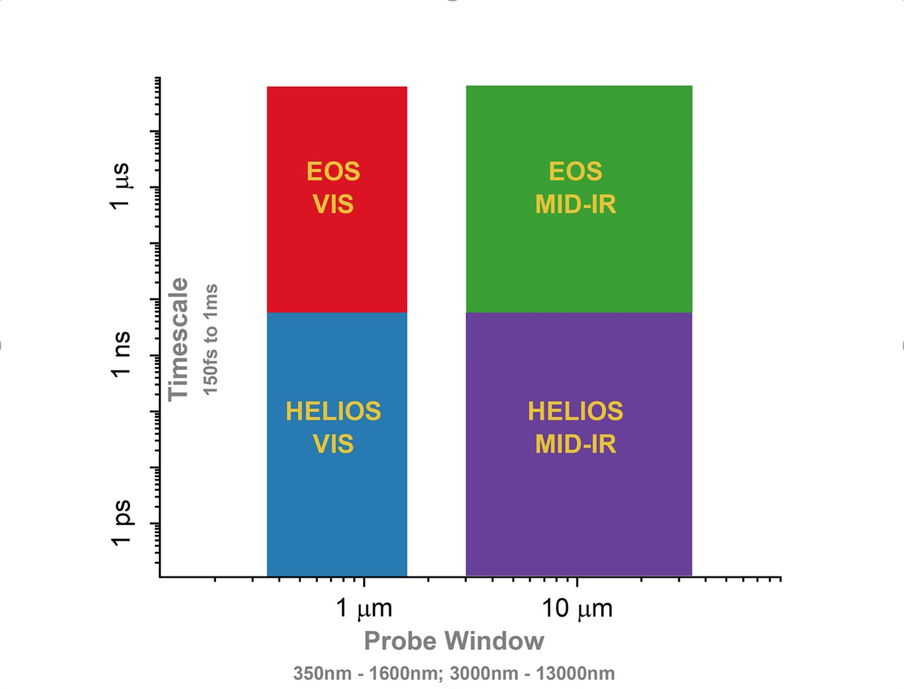

The facility allows measurements of time-resolved change of the absorption spectra (Transient Absorption) with femtosecond (10-14 s) time resolution and up to microsecond timescales with spectral windows in UV-VIS-NIR, allowing probing all possible excited state transitions. It consists of LIBRA Ti:Sapphire amplifier (Coherent Inc.), OPerA Solo optical parametric amplifier (Coherent Inc.), Helios transient absorption spectrometer (Ultrafast Systems), and EOS transient absorption spectrometer (Ultrafast Systems). The Ti:Sapphire amplifier delivers 45fs pulses at 1kHz rate, with total power of 4.0W at 800nm wavelength. Optical parametric amplifier allows tuning of the excitation wavelength in the spectral range from 290 – 2600nm, with average power of 50mW and pulse duration 50fs. Transient absorption spectrometer allows measurements in 350 – 1600nm spectral region (probing range), and on <1ms time range. A recent addition is the MID-IR system (Ultrafast Systems) for direct probing vibrational modes in molecules (3500cm-1 to 800cm-1). Allowing for the direct monitoring of molecular bonds on light-initiated processes. This can even be extended to millisecond timescales for monitoring of diffusion limited processes.

Since the foundation of LASER COMPONENTS Detector Group, Inc. in 2004 we have built a product range comprising high quality APDs as well as low cost versions.

Marking using these lasers is referred to as “Cold Marking” — this is because they can mark and process materials with minimal heat damage (this is due to their incredibly high absorption rate on a variety of materials).

The light itself is bounced between two mirrors within the tube and (once it’s strong enough) is eventually redirected to a final mirror inside the laser head, which redirects the light through a focus lens to the working material.

Optical Bonding Adhesive for Wearable Devices. Optical bonding is a process used to attach a cover glass or touch panel to an LCD or OLED display to improve the ...

2022325 — However, if you're starting from scratch or the glass windows have completely shattered, the general thickness for shed windows when using a ...

ProScope-EDU 1080P WIFI Microscope. The ProScope EDU WiFI Microscope features a super sharp 1080P (3MP) imager, 10X to 230X zoom, finite adjustable stand, apps ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500