Features and Operation of the KA Mount - pentax pk k

Diamond fluorescence is neither good nor bad. Some people find fluorescent diamonds beautiful and fascinating—others may not. Opinions range across the spectrum.

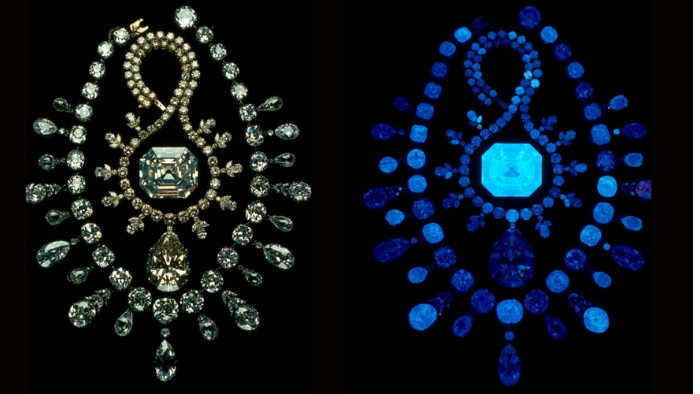

Seen here are seven diamonds seen under daylight-equivalent illumination versus long-wave UV illumination. Photo: Kevin Schumacher/GIA

Chalcogenide, Zinc Selenide, Zinc Sulfide, Calcium Fluoride, Magnesium Fluoride, Potassium Bromide, Silicon, Fused Silica, Sapphire, Germanium

IRRifleOptics

Syntec Optics is a leading provider of design, development, manufacturing, and assembly services for custom infrared optics (IR optics). Our offerings include IR lenses, prisms, windows, mirrors, domes, aspherical lenses, and diffractive lenses.

Infrared camera lens

We collaborate with customers to ensure the optical design meets their performance requirements, such as MTF and FOV. Opto-mechanical designers consider specifications such as mount, focus type, and sealing while conceptualizing IR optomechanical systems. We can incorporate diffractive features in plastic, glass, or chalcogenides via diamond turning or molding. Diffractive surfaces provide chromatic correction in infrared imaging.

No, fluorescence does not cause haziness in diamonds. Fluorescence can increase the pre-existing haziness of a diamond caused by light-scattering defects, thus reducing the contrast in its face-up pattern, but it does not cause haziness in and of itself. As light-scattering defects are incredibly rare, most consumers don’t need to worry about fluorescence impacting a diamond’s appearance in most lighting situations, even if the diamond has Strong to Very Strong fluorescence. But this does mean that consumers should look at a diamond in person. Any haziness intensified by fluorescence, if present, will be noticeable in (for example) daylight-equivalent lighting.

Precision molding of lenses using Chalcogenide glass affords considerably less expensive production cost in large quantities compared to SPDT (single point diamond turning) and a definitive and competitive price-performance ratio. Chalcogenide glass has attractive optical properties over a broad IR spectrum range and is suitable for the molding manufacturing process.

The Equal Employment Opportunity Clause required under Executive Order 11246, and the employee notice clause pertaining to employee rights under the National Labor Relations Act, set forth in 29 CFR Part 471 Appendix A to Subpart A, are incorporated by reference in this purchase order. By accepting this purchase order, vendor additionally certifies that, to the extent applicable, this contractor and subcontractor shall abide by the requirements of 41 CFR §§ 60-1.4(a), 60-300.5(a) and 60-741.5(a). These regulations prohibit discrimination against qualified individuals based on their status as protected veterans or individuals with disabilities and prohibit discrimination against all individuals based on their race, color, religion, sex, sexual orientation, gender identity, or national origin. Moreover, these regulations require that covered prime contractors and subcontractors take affirmative action to employ and advance in employment individuals without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, protected veteran status or disability, that it complies with the authorities cited above, and that it does not maintain segregated facilities or permit its employees to perform services at locations where segregated facilities are maintained, as required by 41 CFR 60-1.8.

IRlens material

Syntec Optics has a state-of-the-art metrology department to ensure the quality, precision, and accuracy of infrared optical components and assemblies.

Infrared optical material selection depends on customer requirements. Some of the materials we work with include – Zinc Sulfide (ZnS), Germanium (Ge), Chalcogenide, Silicon, Zinc Selenide, Sapphire, Calcium Fluoride, and Magnesium Fluoride.

Precision molding of infrared optics using Chalcogenide glass is a less expensive production option for large quantities. We can mold finished, spherical, aspherical, and diffractive lens geometries.

Infrared lens photography

Customers engage Syntec Optics to conduct diffractive lens design. Once the suitable material is determined, the first step of the design investigation is to design a single-precision diffractive element. The diffractive lens design is optimized at a single wavelength and aspheric terms are added to both surfaces. The correction with up to 6th order aspheres is quite good as long as the field of view is small and there is a single wavelength.

Our infrared optics manufacturing capabilities cover the entire infrared spectrum: near-infrared (NIR 0.7µm to 0.9µm), short-wave infrared (SWIR 0.9µm to 2.3µm), mid-wave infrared (MWIR 3µm to 5µm), and long-wave infrared (LWIR 8µm to 14µm).

The center diamond is an H color diamond with Strong to Very Strong fluorescence. The two diamonds flanking it on either side are H color diamonds with no fluorescence. There is no visible difference in color or transparency. Courtesy: Jian Xin (Jae) Liao

Some trade professionals think blue fluorescence enhances a diamond’s appearance, especially in diamonds with I to M color grades. Bluish fluorescence can make a faint yellowish diamond appear more colorless in UV light, which is part of natural daylight. As a result, diamonds with color grades I to N with a very strong to medium bluish fluorescence may have a slightly higher per-carat price than diamonds with similar color grades that do not fluoresce.

Nonetheless, the association between fluorescence and haziness persists, and diamonds in the D to H range with very strong fluorescence often sell for less than diamonds that do not have fluorescence, even though their color and transparency are most likely unaffected by their fluorescence. These diamonds may prove to be a good deal. If you’re not familiar with the GIA Color Scale, learn more with the GIA Diamond Color Chart.

In order to study the effect of blue fluorescence on diamond appearance, GIA scientists assembled sets of E, G, I, and K color-grade diamonds. The diamonds in each set were as similar as possible except for the intensity of their blue fluorescence. Diamond graders, trained professionals, and average observers viewed the diamonds in controlled conditions to make a judgment about their appearance. It seems that, for the average observer, meant to represent the jewelry-buying public, no systematic effects of fluorescence were detected. In general, viewers perceived that strongly blue fluorescent diamonds had a better color appearance when viewed table-up. Most observers saw no relationship between fluorescence and transparency.

Ir OpticsBinoculars

Many commercial LWIR lenses (e.g. IR diamond-turned lens) are currently two-element solutions. Diamond turning is a main component of the manufacturing requirements, although AR coatings are also a critical part of the process. Coating IR materials can be quite challenging and expensive because of the relatively thick layers that are required.

Infrared lens for iPhone

No. Only about 25% to 35% of diamonds exhibit some degree of fluorescence in reaction to long-wave UV light. More than 95% of these diamonds fluoresce blue. A rare few fluoresce other colors such as yellow or green.

Fluorescence is the glow you sometimes see when an object emits visible light. Some diamonds fluoresce when they are exposed to long-wave ultraviolet (UV) rays from sources like the sun. This can cause them to emit a bluish light or more rarely, a yellow or orangy light. Once the UV light source is removed, the diamond stops fluorescing.

Customers also engage Syntec Optics to develop IR electro-optics solutions owing to our proven optical assembly capabilities in a cleanroom environment. Our expert assembly team also performs in-line and end-of-line testing to ensure optimum performance of infrared optical systems.

Diamond fluorescence is a fascinating phenomenon where diamonds glow when exposed to long-wave UV rays. It can sometimes increase or decrease the value of a diamond. It can also affect diamond appearance—or not. How should you take fluorescence into account when choosing the perfect diamond? In this article, we’ll cover:

All objects emit heat/infrared radiation invisible to human eyes. Infrared optics convert this radiation into images visible to human eyes.

Infrared lens glasses

Customers engage Syntec Optics to conduct optical design development of IR electro-optics (LWIR lenses). An example is a request for the following specification: 25 mm EFL, f/1, and a FOV. The camera chip size is 640×512 with 17 μm pixels so the diagonal is 13.93 mm, which yields a nominal FOV of ±15.57°. The other requests for the design investigation include correction for wavelengths between 8-12 μm and the material selection is intended to be ZnS, Ge, or Chalcogenide. Syntec can work with a variety of requests based on custom optics applications. The Refractive index of Ge is 4, ZnS is 2.2, and Chalcogenide is 2-3.

IROptical Sensor

Use of this site signifies your agreement to its terms of use. © 2002 – 2024 Gemological Institute of America Inc. GIA is a nonprofit 501(c)(3) organization. All rights reserved.

Syntec develops many IR opto-mechanical designs during its investigation process after the camera applications are reviewed. Material selection is key, germanium (Ge), which has almost twice the index of refraction compared to ZnS (i.e. 4 to 2.2). The two-element Ge design provides a significant improvement in imaging when compared to the ZnS solution, see MTF plots.

If you are considering a diamond with bluish fluorescence, look at it under different kinds of lighting, including natural daylight and compare it to other diamonds of the same color grade, and see if you notice any difference. If you do notice a difference, see if you like it!

The opposite is true for diamonds with higher color grades. In the trade, diamonds in the D to H color range with bluish fluorescence are often considered less desirable than similar grade diamonds without fluorescence, because some people believe that bluish fluorescence may cause diamonds to have a hazy or oily appearance. In a recent study, GIA observed that blue fluorescence has little to no impact on transparency except in extremely rare cases where a diamond (such as the Portuguese diamond) has a light-scattering defect. These defects cause haziness that can sometimes be intensified by strong fluorescence, thus reducing the contrast in the face-up pattern of the diamond. Fluorescence does not cause haziness by itself, however. Also, this “overblue” hazy effect occurs in fewer than 0.2% of the fluorescent diamonds submitted to GIA.

Fluorescence is not a grading factor like the GIA 4Cs (color, clarity, cut, and carat weight), but it is an identifying characteristic. GIA Diamond Grading Reports and Diamond Dossiers describe a diamond’s fluorescence by its intensity under long-wave UV light (None, Faint, Medium, Strong and Very Strong). If the fluorescence is Medium, Strong, or Very Strong, the color of the fluorescence will be noted.

Ms.Cici

Ms.Cici

8618319014500

8618319014500