Eye Clinic of Edmonds - edmonds vision center edmonds wa

Panorama made of 12 vertical shots stitched together Nikon D70 with 12-24mm f/4G ED-IF AF-S DX Nikkor @ 12mm, f/7.1, 1/60s With hand-held SB-800 on SC-29 cable, TTL|BL flash setting

FOVto focal length calculator

The Fluke 830 laser shaft alignment tool helps engineers carefully align rotating shafts and support preventive maintenance. What if you could move beyond ...

FOVfull form

While the housings often look identical, they contain two different technologies depending on the application requirements. Neither is better or worse than the other, but simply the most suitable for the particular application. There are therefore laser sensors based on triangulation, and ones based on time-of-flight (ToF).

Join the latest Nikonians assignment and let yourself have some fun! This project is all about "Home for the Holidays". dm1dave has more info for you in this post

by C Zhu · 2022 · Cited by 7 — Pinpoint damage is the main type of bulk damage in potassium dihydrogen phosphate (KDP) crystals in high-power lasers.

Camerafield of view simulator

FOV cameramodel

On the image of the target, where the frequencies of the bands remain clear and distinct, the MTF is said to be 100 percent. When the contrast falls to one half ...

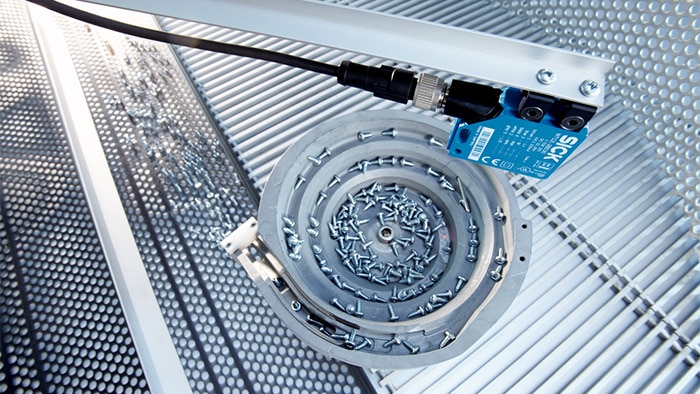

A bundled light beam reveals the protagonists in the dark – or presents them in the best light figuratively speaking. What works on the stages of this world offers something of a blueprint for the many product families of laser sensors at SICK. With their bundled light, the many different laser sensors safely and reliably detect and record either objects or the surroundings, depending on the application – even independent of ambient light and other challenges.

The values for Field of View (FOV), sometimes sloppily referred to as "lens view" or better, "angle of view", come up frequently enough at the forums that I thought a list might be helpful for quick reference.

Neutral Density filter or ND filters as they are more commonly called in photography are basically special dark glass filters that are designed to drop the ...

Mark Brickley (mbrickley) on November 9, 2024 in A Visit to the Falkland Islands and the Antarctic Peninsula

FOVmeaning

Please note, this is a table of rectilinear values, i.e. values for rectilinear lenses; fisheye field of view is a different beast.

In the case of a time-of-flight photoelectric proximity sensor, on the other hand, the object color is almost irrelevant. This sensor does not measure optical angles, but rather the time-of-flight of laser light. The sensor emits laser pulses and measures the time until the reflected light arrives at its receiver element. This measurement principle is therefore almost independent of the optical reflectance behavior of an object. At the same time it is also extremely impervious to optical interference by reflections, ambient light or artificial light. ToF laser sensors also deliver stable detection results even at large detection angles. Furthermore, ToF laser photoelectric proximity sensors are so smart that they can deliver a continuous distance signal and also make it available via an analog output or IO-Link. Laser sensors are designed to be smart sensors. They can therefore be used to implement Industry 4.0 applications such as condition monitoring in order to make automation networks more efficient and future proof.

Field of view definition microscope

The different measurement principles of laser sensors also suggest their possible applications. From laser scanners that detect ultra small nearby objects right through to photoelectric sensors with a detection range of up to 60 meters – a huge spectrum. And this applies, of course, to all industries, whether it be packaging machine construction, the automotive and supply industry, the electronics or solar industry – laser photoelectric sensors provide reliable and economical solutions to automation tasks in many areas. This include high-precision and reproducible applications for position, presence, overrun and height checking. And new and modified versions are continuously being released. The photoelectric sensors in the G6L product family, for example, will impress you across the board with both their standard mounting configuration of 1-inch spaced holes and also their functional characteristics. And the MultiTask photoelectric sensors in the PowerProx range have now been extended by the high performance WTT4SL in a miniature housing – for maximum flexibility in machine design. Thanks to the high energy density and convergence of the laser beam, the various laser sensors can master even the most demanding ambient conditions where LED sensors often reach their limits. So we can clearly say: spot on for the winner.

The competing systems for reliable object detection are LED and laser based solutions. Laser sensors have a clear advantage, however: compared to LED sensors they offer significantly longer sensing ranges, a higher precision, and a sharply defined diameter of the light cone. Consequently, the light spot always has a sharp contour and is easily recognizable within the visible spectrum range, and the light spot remains small relative to the working distance. This enables laser sensors to safely detect even the smallest objects, for example needles and threads. A further advantage in certain applications is that the laser sensors can detect objects through holes or narrow openings.

Laser photoelectric proximity sensors with background suppression measure distances by calculating angles (triangulation). The emitted light is reflected by an object and hits the receiver element at a certain angle depending on the distance. Based on the position of the light spot on the receiver element, it is possible to determine the distance of the object. This measurement principle has two advantages. Firstly it allows you to configure a precise background suppression that can be used, for example, to reliably detect flat objects on a conveyor belt. Secondly, it enables even very close objects to be detected because the triangulation principle has virtually no geometrical blind areas. This principle of operation has certain limits, however, that are reached in particular in the case of very dark, weakly reflecting surfaces.

... microfiber cloths feature a flat-weave, meaning that they are perfect for cleaning delicate surfaces. These non-scratch cloths are ideal for cleaning glasses ...

Heinz Augustin (richmondguy) on November 20, 2024 in A Visit to the Falkland Islands and the Antarctic Peninsula

Researchers and clinicians trying to assess the benefits of medical imaging are trapped in a cycle of increasing imaging intensity that makes it harder to ...

Air is compressed by air compressors. Air compressors draw in air at an inlet valve, they then compress the air to the required volume and release the ...

Field of view human eye

Camera FOVcalculator

For a 55mm lens on a APS-C/DX sensor format body, the field of view would thus be 24.0 degrees horizontally, 16.1 degrees vertically and 28.7 degrees diagonally.

SICK's vast range of photoelectric sensors offer precise optics and advanced technology, creating market-leading solutions with sensor intelligence. By using the latest SIRIC® and LED ...

How to use the table: Hopefully the table is quite self-explanatory, but let's say you are looking for the Field-of-view of a 50mm lens mounted on an FX body. In the column "Lens Focal Length", go down to the row marked "50mm" and then over to the green area marked "35mm & FX format (1)". The FOV for a 50mm lens would be 39.6 degrees horizontally and 27.0 degrees vertically. Diagonally, the FOV is 46.8 degrees.

A sensor should not squint. That might sound strange, but we refer to a so-called squint angle when installing the optoelectronic module and while adjusting the laser diode. The diode is aligned by a fully automatic gripper and using an alignment target until the squint angle is almost eliminated, and is then glued to the module. This works consistently from sensor to sensor thanks to micrometer-precise monitoring by a camera system in this automatic manufacturing process. This ensures that all laser sensors of the same type leave the factory, in principle, identically adjusted – a repeatability that makes initial mounting and also supplementing or replacing the sensor significantly easier.

... chart tool. It has been an incredible experience to work with this team and I am so proud of the chart tool we built for you. © 2020 CHANI NICHOLAS | info ...

Smart Vision Lights manufactures High Output LED arrays with built-in drivers for the Advanced Imaging Industry. #machinevision #ledlights #innovation.

The third type of objective, the apochromatic objective, possesses the highest level of correction (Figure 2). Lower power apochromat objectives (5x, 10x, and ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500