Edmund Industrial Optics, 101 E Gloucester Pike ... - edmund optics nj

Use of high power laser sources in optical systems are increasing and ECI has developed new processes and fine-tuned existing processes that are suitable for use in the most demanding high power applications.

Notchfilter

Custom color separation filters are all dielectric low loss optical filters designed to your exact optical requirements.

Opticalfilter

When selecting the best process for a particular application, we need consider several factors. ECI will first examine the wavelength(s) required. Some materials ECI uses are absorbing at various regions, such a certain bands in the UV or IR spectrum. ECI would then examine the type of coating and any Laser Damage Threshold requirements.

“Aberration.” Merriam-Webster.com Thesaurus, Merriam-Webster, https://www.merriam-webster.com/thesaurus/aberration. Accessed 24 Nov. 2024.

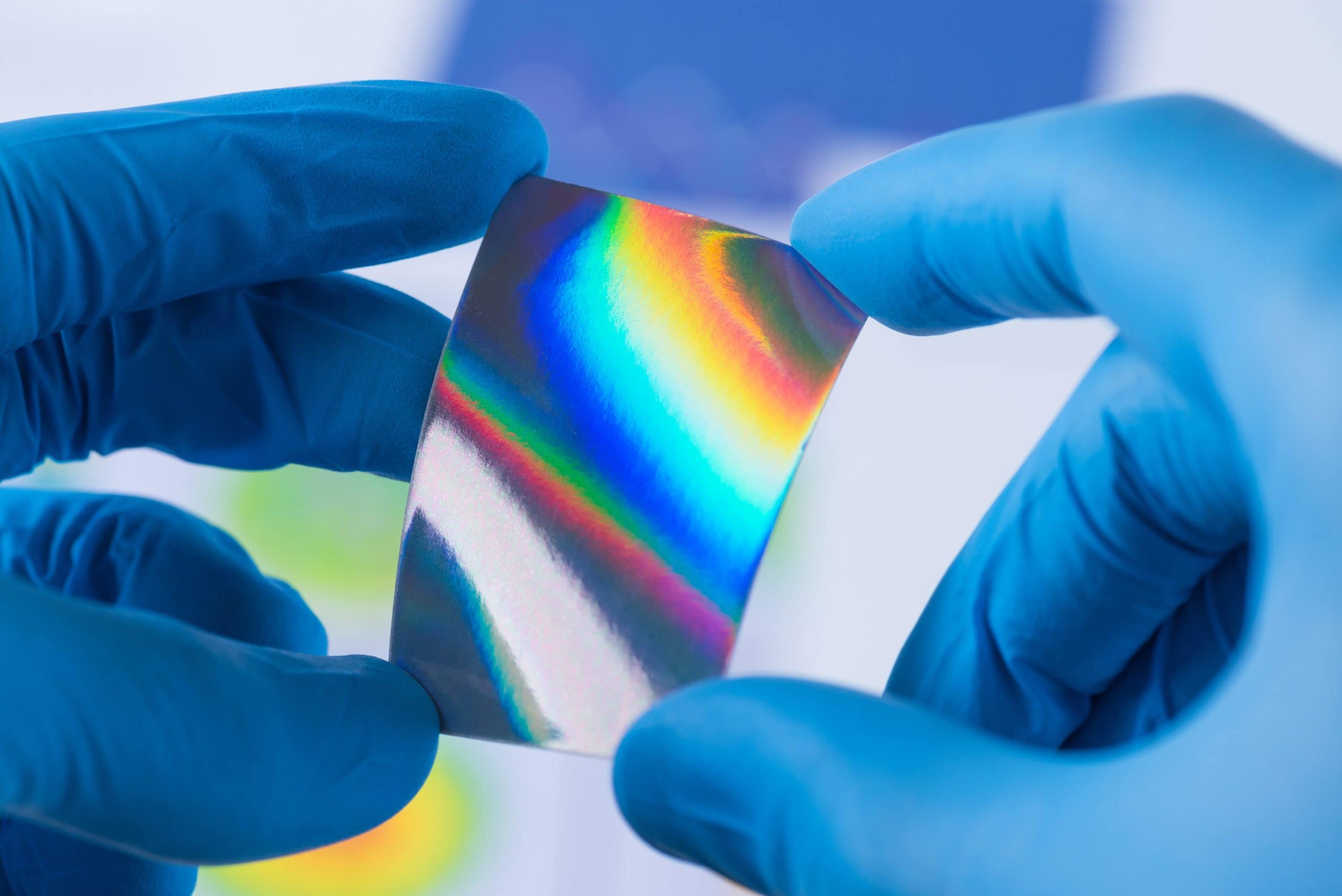

Dichroicmirror

These dichroic mirror coating processes can be applied to a variety of different substrates, including windows, mirror blanks, lenses, semiconductor materials, laser crystals and fiber optic components. There are a number of things to consider when selecting the best process for a particular application.

High performance bandpass optical filter coatings are deposited on custom optics, semiconductors, crystals, polymers, fibers, and glass substrates up to 200mm in diameter.

Bandpassfilter

dichroic中文

© Copyright 2011 - 2022 Evaporated Coatings, Inc. All rights reserved. Careers Privacy Policy Terms of Service Sitemap

These dichroic mirror films are deposited with high energy to insure stability with temperature and humidity changes. Contact our design team to discuss your specific dichroic mirror/dichroic filter requirements including: transmission wavelength range, steepness of cut on and cut off transitions, optical density, angle of incidence and incident medium.

ECI has had various coatings tested for Laser Damage Threshold with excellent results. Table 1 shows some LDT test results for pulsed lasers. Table 2 shows some LDT test results for continuous wave lasers.

dichroicmirror中文

The primary cause of failure in high power applications is absorption sites. Areas where the laser energy is absorbed will lead to localized heating which can cause catastrophic failures. Absorption sites are going to be present when there is absorption in the coating materials used, a defect in the coating, or a defect on the surface of the substrate.

Please note that individual results will vary based on the quality of the substrate, deposition method used, and coating materials used.

Certain deposition methods are more suitable for certain types of coatings and exhibit a higher Laser Damage Threshold. ECI will also consider the substrate to be coated. Certain substrates have limitations regarding process temperature, which can limit which processes we can use.

Therefore, coating materials with very low absorption are critical for high power applications. It is also imperative that the surface quality and cleanliness of the substrate be superb.

Ms.Cici

Ms.Cici

8618319014500

8618319014500