Dove Prisms - dove prism

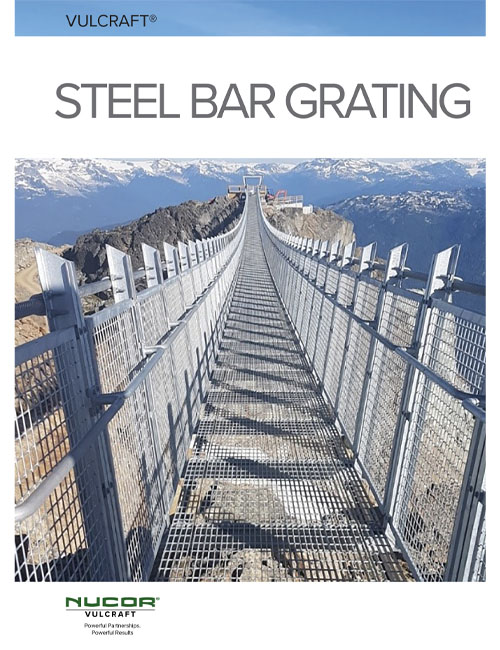

Vulcraft is your premier full-service grating supplier. Whether you're in need of stock panels or custom fabrication, we have you covered. Working with Vulcraft as your trusted partner, you will experience a seamless journey from concept to fully fabricated, ready-to-install grating.

Gratingin construction

Rectangular steel bar stair treads provide a high strength and stiffness-to-weight ratio and are available with a serrated surface when additional safety is required.

When the oil-immersion objective lens is in use, the difference between the light-bending ability (or refractive index of the medium holding the sample) and the objective lens becomes important. Because the refractive index of air is less than that of glass, light rays are bent or refracted as they pass from the microscope slide into the air, as shown in Figure 3-9. Many of these light rays are refracted at so great an angle that they completely miss the objective lens. This loss of light is so severe that images are significantly degraded. Placing a drop of immersion oil, which has a refractive index similar to glass, between the slide and the objective lens decreases this refraction, and increases the amount of light passing from the specimen into the objective lens. This results in greater resolution and a clearer image.

A versatile product with applications beyond standard industrial usage, Standard Duty steel bar grating can be used in applications as wide-ranging as platforms, catwalks, and mezzanines to fencing, benches, shelving, or ventilation covers. The only limit to this product’s usage is imagination. Our Standard Duty steel bar grating is available in bare steel, shop primed, or hot dip galvanized.

The light from the illuminating source is passed through the substage condenser. The condenser serves two purposes; it regulates the amount of light reaching the specimen and it focuses the light coming from the light source. As the magnification of the objective lens increases, more light is needed. The iris diaphragm (located in the condenser), regulates the amount of light reaching the specimen. The condenser also collects the broad bundle of light produced by the light source and focuses it on the small area of the specimen that is under observation.

Welded stair treads are widely used for their strength and ease of installation and are universally used in industrial and commercial applications.

BarGrating

Figure 3.1. The light microscope. A modern light microscope. This is an example of the kind used in the teaching labs at the University of Wisconsin-Madison. The various parts of the microscope are labeled. Please take the time to become familiar with their names.

The compound microscope used in microbiology is a precision instrument; its mechanical parts, such as the calibrated mechanical stage and the adjustment knobs, are easily damaged, and all lenses, particularly the oil immersion objective, are delicate and expensive. Handle the instrument with care and keep it clean.

First let us consider a primary feature of all microscopes, the light source. Proper illumination is essential for effective use of a microscope. A tungsten filament lamp usually serves as the source of illumination. If reflected illumination is used, a separate lamp provides a focused beam of light which is reflected upward through the condenser lenses by a mirror.

The microscope, as shown in Figure 3-1, is one of the most important instruments utilized by the microbiologist. In order to study the morphological and staining characteristics of microorganisms such as bacteria, yeasts, molds, algae and protozoa, you must be able to use a microscope correctly.

Metalgrating

Areas that support heavy loads need a product that is durable, strong, and safe. Our Heavy Duty steel bar grating is resistance-welded using an automated electric hydraulic welding process, which uses high temperatures and high pressure to fuse the bearing bars and cross bars together to form a strong, permanent joint. This process creates grating that can support loads in airfields, industrial plants, truck and bus terminals, parking lots, and railroad yards.

The microscope is basically an optical system (for magnification) and an illumination system (to make the specimen visible). To help understand the function of the various parts of the microscope, we will follow a ray of light as it works its way through a microscope from the light source, through the lenses, up to the eye. Figure 3-8 traces the path of light through the parts of the microscope

On both sides of the base of the microscope are the course and fine adjustment knobs, used to bring the image into focus. Rotation of these knobs will either move the specimen and the objectives closer or farther apart. The coarse adjustment moves the nosepiece in large increments and brings the specimen into approximate focus. The fine adjustment moves the nosepiece more slowly for precise final focusing. In some microscopes, rotation of the fine and course adjustment knobs will move the stage instead of the nosepiece.

Gratingnear me

Figure 3.9. Refraction of light at 100X. Light passing out of the slide, into the air, toward the objective lens is refracted, due to the different in refractive index between air and glass. While the bending cause by this difference is not important at 100X and 400X, at 1000X this refraction is problematic, causing blurring of the image and significant loss of light. Immersion oil has a refractive index very similar to that of glass. Placement of a drop of oil between the objective lens and the slide prevents the bending of light rays and clarifies the image. The blue dashed line represents a potential light ray if immersion oil is not present. The red dashed line represents a light ray if immersion oil is present.

Magnification alone is not the only aim of a microscope. A given picture may be faithfully enlarged without showing any increase in detail. The true measure of a microscope is its resolving power. The resolving power of the lens is its ability to reveal fine detail and to make small objects clearly visible. It is measured in terms of the smallest distance between two points or lines where they are visible as separate entities instead of one blurred image. The resolving power of the objective lens, engraved on the lens, allows us to predict which objective lens should be used for observing a given specimen. However, having good resolution in the microscope does not guarantee a visible image, the resolving power of the human eye is quite limited. Often further magnification is needed to obtain a good image.

We pride ourselves on delivering tailored solutions to meet your project’s requirements. Our teams in Sales, Engineering, Drafting, and Fabrication will work collaboratively with you to bring your vision to life. From initial structural drawings to detailed grating drawings, we employ cutting-edge computer-aided design and 3-D software applications to ensure precision and efficiency at every step.

Gratingmeaning

Vulcraft’s most popular grating product, and is also the most commonly used type of grating in the industrial flooring market.

Nearly all sizes in Standard Mesh Type 19-4 (Type 30-102) are readily available in our warehouses or stocked on the shelves of our distributors.

Gratingin Physics

Our BAR GRATING DESIGN AID is available to help you find the perfect platform and tread size for your design needs. It also takes horizontal and vertical dimensions into account, helping you to determine the number of steps needed to meet code requirements.

When your project requires strength and durability for heavy-load areas, Vulcraft heavy duty welded steel bar grating is your solution.

Gratingfood

As both a manufacturer and fabricator of grating, we possess the unique ability to provide comprehensive "One Source" solutions for all your grating needs. Our commitment to continuous improvement drives us to maximize efficiencies throughout the process.

Figure 3.1. The light microscope. A modern light microscope. This is an example of the kind used in the teaching labs at the University of Wisconsin-Madison. The various parts of the microscope are labeled. Please take the time to become familiar with their names.

Light then passes up through the slide and into the objective lens where the first magnification of the image takes place. Magnification increases the apparent size of an object. In the compound light microscope two lenses, one near the stage called the objective lens and another in the eyepiece, enlarge the sample. The magnifying power of an objective lens is engraved in the lens mount. Microscopes in most microbiology laboratories have three objective lenses: the low power objective lens (10X), the high-dry objective lens (40X) and the oil-immersion objective lens (100X). The desired objective lens is rotated into working position by means of a revolving nosepiece.

Vulcraft’s wide range of steel bar grating includes standard, heavy duty, and stair treads, and is manufactured with versatility in mind. With 45 offices across the country and a fleet of company-owned trucks, we're ready to manufacture and deliver standard grating panels quickly and accurately to your doorstep. We also have the expertise to estimate, detail, and custom fabricate ready-to-install grating in virtually any configuration for specialized projects. With our unparalleled service and the backing of the Nucor family of quality companies, Vulcraft is the one-stop-shop for steel bar grating solutions.

Steelgrating

Our BAR GRATING DESIGN AID is available to help you find the perfect platform and tread size for your design needs. It also takes horizontal and vertical dimensions into account, helping you to determine the number of steps needed to meet code requirements.

Common uses for this product include flooring, driveways, subways and tunnel ventilation grilles, curb inlet grates, ramps, and docks.

Your satisfaction is our top priority, and we're here to deliver exceptional products and service every step of the way.

Figure 3.8. The path of light through a microscope. Modern microscopes are complex precision instruments. Light, originating in the light source (1), is focused by the condensor (2) onto the specimin (3). The light then enters the objective lens (4) and the image is magnified. Light then passes through a series of glass prisms and mirrors, eventually entering the eyepiece (5) where is it further magnified, finally reacing the eye.

Our BAR GRATING DESIGN AID is available to help you find the perfect platform and tread size for your design needs. It also takes horizontal and vertical dimensions into account, helping you to determine the number of steps needed to meet code requirements.

The image of the specimen continues on through a series of mirrors and/or prisms that bend it toward the eyepiece. A further magnification takes place at the eyepiece producing what is called a virtual image. Total magnification is equal to the product of the eyepiece magnification and the objective magnification. Most often eyepiece lenses magnify 10-fold resulting in total magnifications of 100, 400, or 1000X, depending upon which objective is in place. Many modern microscopes will also have focusable eyepieces to compensate for differences between individuals and even between individual's eyes. The adjustment of these is important and is described below.

Ms.Cici

Ms.Cici

8618319014500

8618319014500